An efficient sterilization composition containing hexamethylene flusulfamide

A technology of cyclohexanesulfanilamide and a composition is applied in the application field of a high-efficiency bactericidal composition on crop diseases, and achieves the effects of high control efficiency, reduction of residual amount and alleviation of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

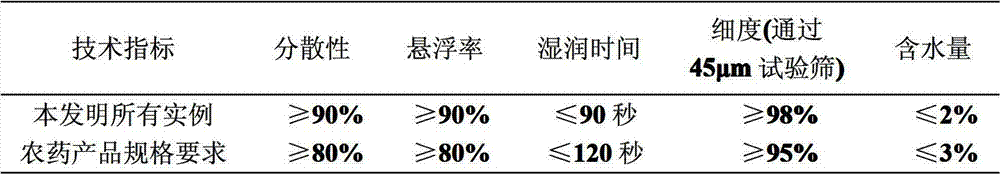

[0040] Embodiment 1~15 wettable powder

[0041] Mix cyclohexasulfame, active ingredient B, dispersant, wetting agent, and filler, mix evenly in a mixing tank, pulverize through a jet mill and mix evenly, then the wettable powder product of the present invention can be made . See Tables 1, 2, and 3 for details.

[0042] Table 1 Embodiment 1~5 each component and content

[0043]

[0044] Each component and content of table 2 embodiment 6~10

[0045]

[0046] Table 3 Embodiment 11~15 each component and content

[0047]

[0048]

Embodiment 16~30

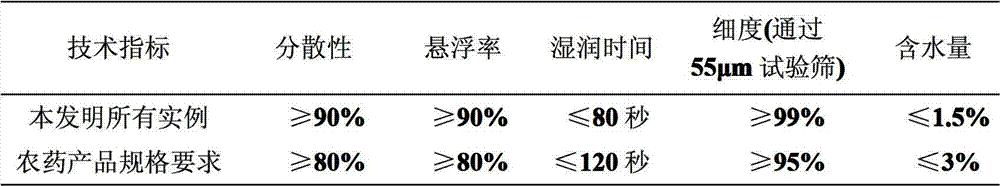

[0049] Embodiment 16~30 water dispersible granules

[0050]Combine cyclohexasulfame, active ingredient B, dispersant, wetting agent, disintegrating agent, filler, etc. through airflow pulverization to obtain the required particle size, and then add binder (optional) and other additives to obtain Granulation materials. The water-dispersible granule product of the present invention can be obtained after quantitatively sending the material into the fluidized bed granulation dryer for granulation and drying. See Tables 4, 5 and 6 for details.

[0051] Table 4 Embodiment 16~20 each component and content

[0052]

[0053] Table 5 Embodiment 21~25 each component and content

[0054]

[0055]

[0056] Table 6 Embodiment 26~30 each component and content

[0057]

Embodiment 31~45

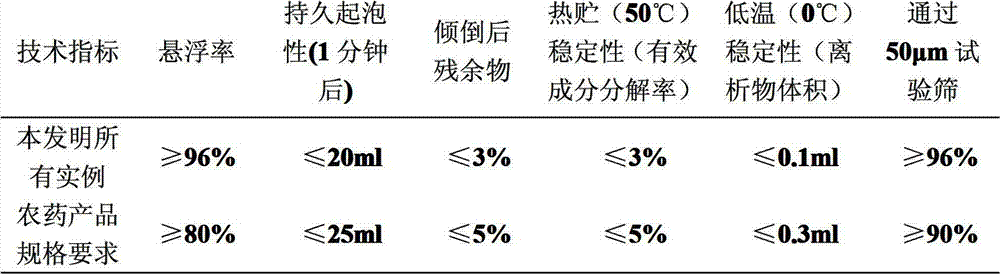

[0058] Embodiment 31~45 suspending agent

[0059] Dispersant, wetting agent, defoamer, thickener (can be added or not), antifreeze agent (can be added or not), mixed evenly through high-speed shearing, add cyclohexasulfame and active ingredient B, in Ball milling in a ball mill for 2 to 3 hours, so that the particle size is all below 5 μm, and the balance is supplemented with deionized water, and the suspension product of the present invention can be obtained. See Tables 7, 8, and 9 for details.

[0060] Table 7 Embodiment 31~35 each component and content

[0061]

[0062]

[0063] Add deionized water to 100%

[0064]

[0065] Table 9 Embodiment 41~45 each component and content

[0066]

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com