Compound instant health care rice flour

A rice noodle and instant technology, applied in the field of rice noodle, can solve the problems that GABA cannot meet the needs of the body, the accumulation of GABA is difficult, and the production process is complicated, so as to achieve high nutritional value, enhance physiological function, and improve the effect of entrance and edibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

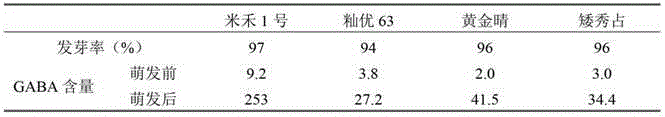

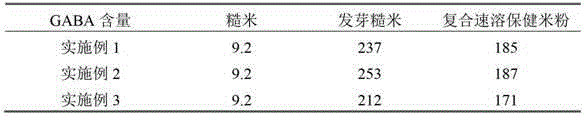

[0032] Select the high-quality fresh Mihe No. 1 rice produced in the year, go through the husking machine, and then go through the selection machine to remove the grains, diseased grains, impurities, etc. to make brown rice; the brown rice is rinsed with clean water, soaked in clean water, The soaking time is 10 hours, the soaking temperature is 33°C, and the water is changed every 4 hours during the soaking process; the brown rice after soaking is taken out and cultured in a germinator in the dark for 30 hours, the germination temperature is 34°C, 12 hours before germination, and the relative humidity is controlled at 75- 80%, ventilation once every 4 hours; relative humidity is controlled between 90-95% in the late germination period of 18 hours, ventilation once every 0.5 hours, rinse every 4 hours; after germination, put it in a hot air dryer Dried at 40°C until the moisture content is less than 15%, and then crushed by a grinder with a built-in 60-mesh sieve to obtain germ...

Embodiment 2

[0034]Choose the high-quality fresh Mihe No. 1 rice produced in the year, go through the husking machine, and then go through the selection machine to remove the grains, diseased grains, impurities, etc. to make brown rice. After the brown rice is rinsed with clean water, it is soaked in clean water. The soaking time is 16 hours, the soaking temperature is 32°C, and the water is changed every 4 hours during the soaking process; the brown rice after soaking is taken out and cultured in a germinator in the dark for 48 hours, the germination temperature is 32°C, 12 hours before germination, and the relative humidity is controlled at 75- 80%, air change once every 4 hours; relative humidity is controlled between 90-95% in the 36h late germination period, air change once every 0.5h, rinse every 4 hours; after germination, put in a hot air dryer Dried at 60°C until the moisture content is less than 15%, and then crushed by a grinder with a built-in 60-mesh sieve to obtain germinated ...

Embodiment 3

[0036] Choose the high-quality fresh Mihe No. 1 rice produced in the year, go through the husking machine, and then go through the selection machine to remove the grains, diseased grains, impurities, etc. to make brown rice. After the brown rice is rinsed with clean water, it is soaked in clean water. The soaking time is 14 hours, the soaking temperature is 28°C, and the water is changed every 4 hours during the soaking process; the brown rice after soaking is taken out and cultured in a germinator in the dark for 44 hours, the germination temperature is 29°C, and the relative humidity is controlled at 75-12 hours before germination. 80%, ventilation once every 4 hours; relative humidity controlled between 90-95% for 32 hours in the late germination period, ventilation once every 0.5 hours, rinse every 4 hours; after germination, put in a hot air dryer Dried at 60°C until the moisture content is less than 15%, and then crushed by a grinder with a built-in 60-mesh sieve to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com