Method and system for quickly producing lead-free multi-flavor multi-layered preserved egg

A multi-taste, preserved egg technology, applied in the field of food science, can solve the problems of not being able to guarantee the layers of egg white and egg yolk, and cannot meet commercial needs, and achieve the effects of elastic egg white, convenient transportation, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

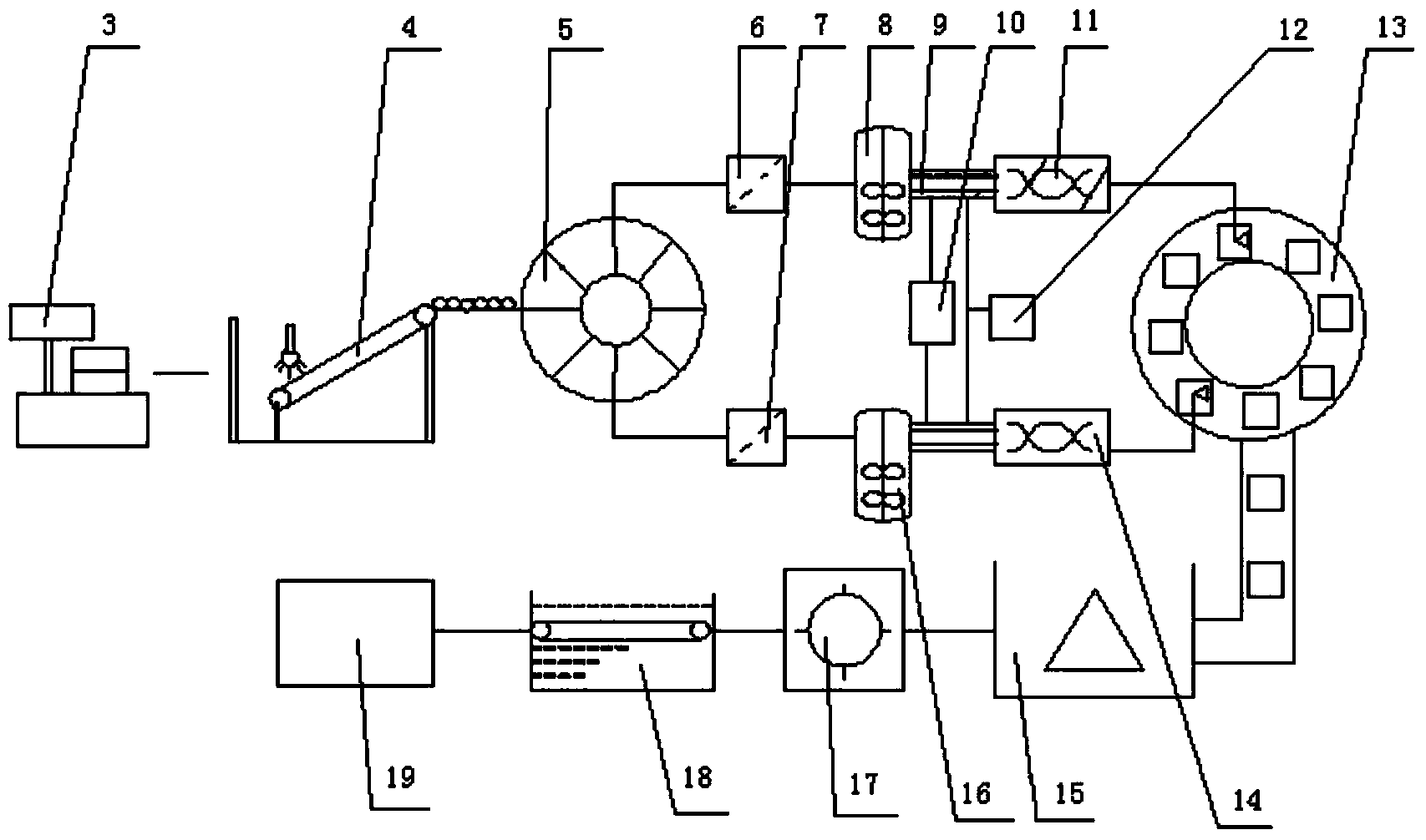

[0036] A method for rapidly producing lead-free multi-taste preserved eggs, the specific steps are as follows:

[0037] (1) Egg selection and egg washing: Strictly select fresh poultry eggs (including eggs, duck eggs, goose eggs, quail eggs, ostrich eggs, etc.), remove cracked, damaged, old and blood-spotted eggs and other inferior eggs, and wash them with water Let dry and set aside.

[0038] (2) Preparation of feed liquid: Weigh food-grade sodium hydroxide and prepare it into an alkaline solution with a mass concentration of 3.2%, weigh sodium chloride and prepare it into a sodium chloride solution with a mass concentration of 2.1% .

[0039] (3) Beating eggs and separating egg whites and egg yolks: put the washed poultry eggs into the egg beater, and divide them into two parts after passing through the egg white and egg yolk separator. In the material tank for use.

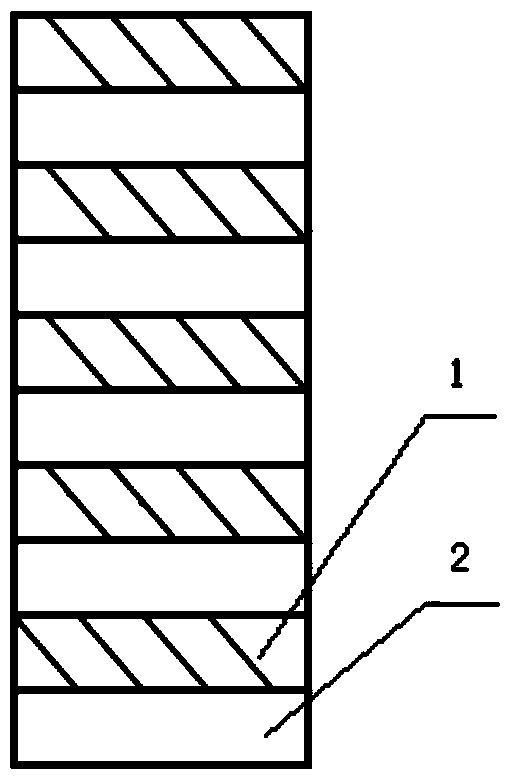

[0040] (4) Production of Preserved Eggs:

[0041] Take out 100 kg of egg white from the egg white storag...

Embodiment 2

[0048] A method for rapidly producing lead-free multi-taste preserved eggs, the specific steps are as follows:

[0049](1) Egg selection and egg washing: Strictly select fresh poultry eggs (including eggs, duck eggs, goose eggs, quail eggs, ostrich eggs, etc.), remove cracked, damaged, old eggs, blood-spotted eggs and other inferior eggs, and wash them with water Let dry and set aside.

[0050] (2) Preparation of feed liquid: Weigh food-grade sodium hydroxide and prepare it into an alkaline solution with a mass concentration of 3%, weigh food-grade sodium chloride and prepare it into a chloride solution with a salt concentration of 2%. sodium solution.

[0051] (3) Beating eggs and separating egg whites and egg yolks: put the washed poultry eggs into the egg beater, and divide them into two parts after passing through the egg white and egg yolk separator. In the material tank for use.

[0052] (4) Production of Preserved Eggs:

[0053] Take out 100 kg of egg white from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com