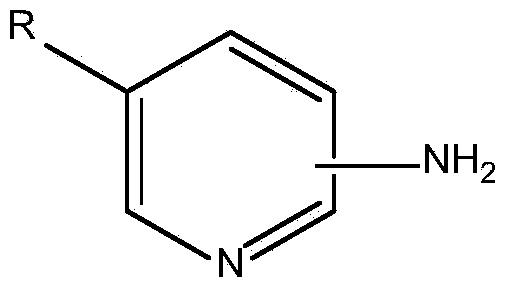

Method of aminopyridine modified resin for adsorbing rhodium octanoate dimer and metal ions

A technology of aminopyridine and modified resin, applied in chemical instruments and methods, ion exchange, selective adsorption, etc., can solve the problems of long production cycle, large discharge of three wastes, damage, etc., and achieve the effect of simple method and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 8.00g of chlorine ball resin and place it in a dry four-necked bottle, and add 200mL of 1,4-dioxane to reflux for swelling for 3h; accurately weigh 8.30g of 3-aminopyridine and add it to the above solution, and add 17.8g of triethylamine , using electromagnetic stirring (stirring speed is enough to disperse the resin), control the reaction temperature to 60°C, and the reaction time to 6h. After the reaction, use Buchner funnel to suction filter, the solvent can be recycled, and then rinse several times with water, absolute ethanol, acetone, ether, etc., the amount of solvent is about 50 ml each time, and the modified resin is stored in a vacuum oven. , Dry below 60 degrees for later use. The functional group content of the obtained modified resin was 3.1 mmol FG / g resin.

[0034] Pretreatment of 3-aminopyridine modified resin: wash with warm water first, then soak in 0.1mol / L NaOH solution for 17h, wash with water until neutral, then soak with (0.1mol / L) HCl solu...

Embodiment 2

[0036] Weigh 7.50g of polyglycidyl methacrylate into a dry four-necked bottle, add 150mL of 1,4-dioxane under stirring at room temperature, reflux and swell for 3 hours; accurately weigh 10.20g of 2-aminopyridine into the above solution , add 21.3 grams of triethylamine, under the condition of magnetic stirring (the stirring speed can be dispersed by the resin), control the reaction temperature to 70°C, and the reaction time to 4h. Using Buchner funnel suction filtration, the solvent can be recycled, and then washed several times with water, absolute ethanol, acetone, ether, etc., the amount of solvent is about 50 ml each time, the modified resin is in a vacuum oven, less than 60 Dry it for later use. The functional group content of the obtained modified resin was 3.5 mmol FG / g resin.

[0037] Pretreatment of 2-aminopyridine modified resin: wash with warm water first, then soak in 0.1mol / L NaOH solution for 20h, wash with water until neutral, then soak with (0.1mol / L) HCl solut...

Embodiment 3

[0039] Weigh 9.00g of chlorine ball resin and place it in a dry four-necked bottle, add 200mL of toluene, and swell under reflux for 5h; accurately weigh 11.50g of 2-aminopyridine and add it to the above solution, add 23.5g of triethylamine, and stir under magnetic force ( Stirring speed is enough to disperse the resin), control the reaction temperature to 55°C, and the reaction time to 6h. After the reaction, use Buchner funnel to suction filter, the solvent can be recycled, and then rinse several times with water, absolute ethanol, acetone, ether, etc., the amount of solvent is about 50 ml each time, and the modified resin is stored in a vacuum oven. , Dry below 60 degrees for later use. The functional group content of the obtained modified resin was 2.9 mmol FG / g resin.

[0040] Pretreatment of 2-aminopyridine modified resin: wash with warm water first, then soak in 0.1mol / L NaOH solution for 15 hours, wash with water until neutral, then soak with (0.1mol / L) HCl solution f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com