Method for preparing regular-triangular-pyramid-shaped bismuth germinate visible-light catalyst

A technology of regular triangular pyramid and bismuth germanate is applied in the field of environmental purification to achieve the effect of simple preparation process, low cost and good visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0025] 1) Under normal temperature (25 °C) and magnetic stirring conditions, 12 mmol of bismuth nitrate pentahydrate and 1 mmol of germanium oxide were dissolved in 70 mL of 5 mol / L sodium hydroxide solution to obtain a mixed solution A; Add 0.5 g cetyltrimethylammonium bromide (CTAB) to mixed solution A to obtain mixed solution B;

[0026] 2) Transfer the above mixed liquid B to a 100 mL stainless steel reaction kettle lined with polytetrafluoroethylene (volume filling degree is 75%), and heat it in a constant temperature oven at 180 °C for 12 h. Cool to room temperature;

[0027] 3) The product obtained in step 2) was centrifuged and washed 5 times with pure water and absolute ethanol, and then dried at a constant temperature of 70 °C for 5 h to obtain regular triangular pyramid Bi 12 GeO 20 catalyst of light.

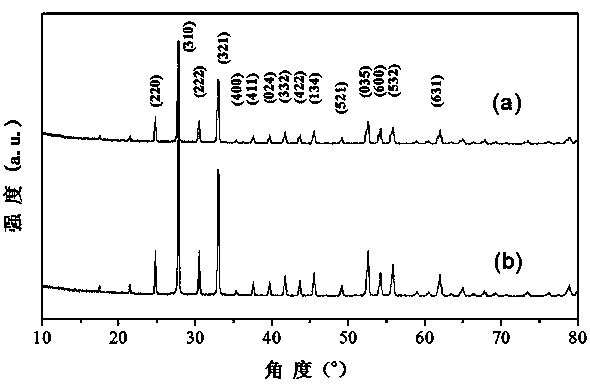

[0028] The XRD spectrogram of the product obtained in this embodiment is shown in figure 1 (b). figure 1 (b) shows that all its XRD peaks are consistent with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com