Method of green synthesis of nanogold through kiwi fruit juice

A kiwifruit juice, green synthesis technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of limited ability to control the shape of nano gold particles, high equipment requirements, high production costs, etc., to achieve the amount of raw materials. The effect of less, low cost and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Draw 20 mL of ultrapure water into a 50 mL Erlenmeyer flask, and add 0.2 mL of chloroauric acid solution, the solution at this time is 0.01% chloroauric acid solution. The resulting solution was heated and stirred in a boiling water bath for 10 minutes.

[0017] 2. Quickly add 1mL of fruit juice, and after stirring for about 30 minutes, stop heating and cool to room temperature. During the reaction process, the color of the mixture gradually changed from colorless and transparent to wine red, such as figure 1 As shown, the color transition indicates the formation of gold nanoparticles.

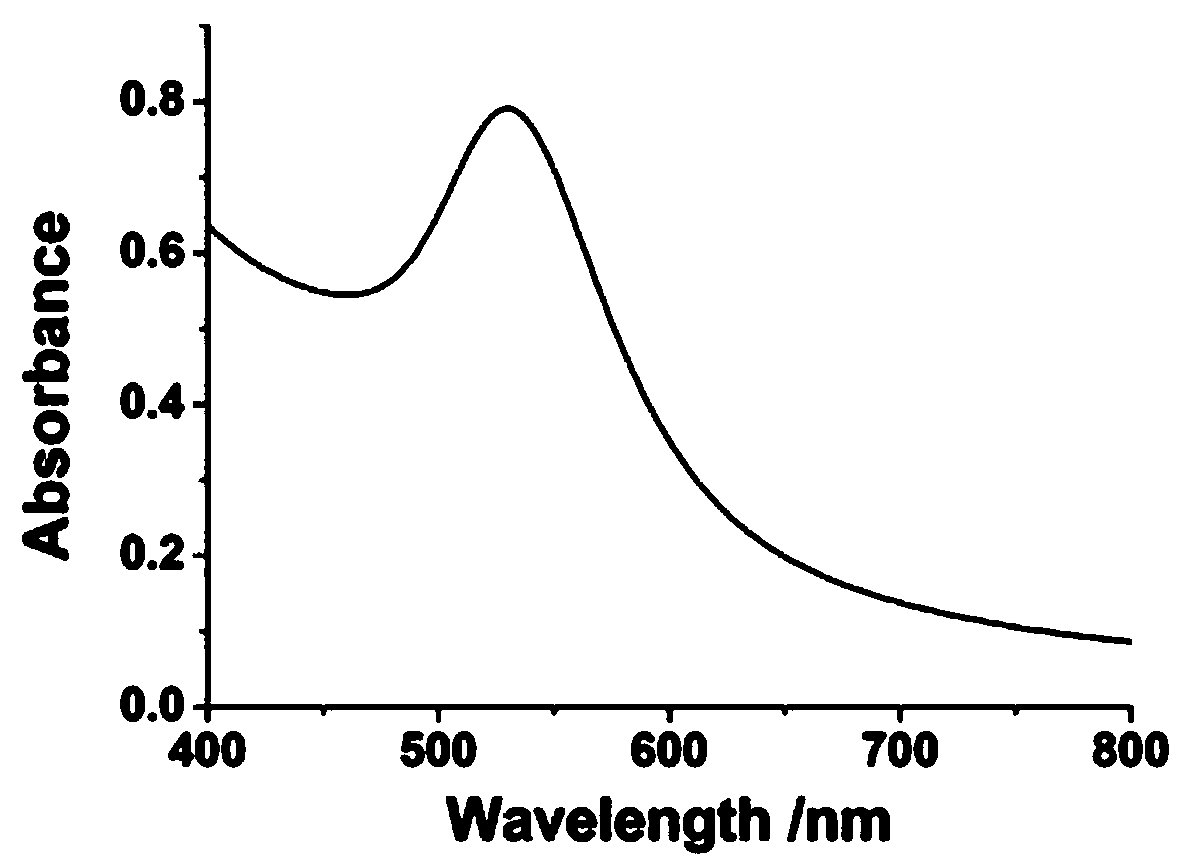

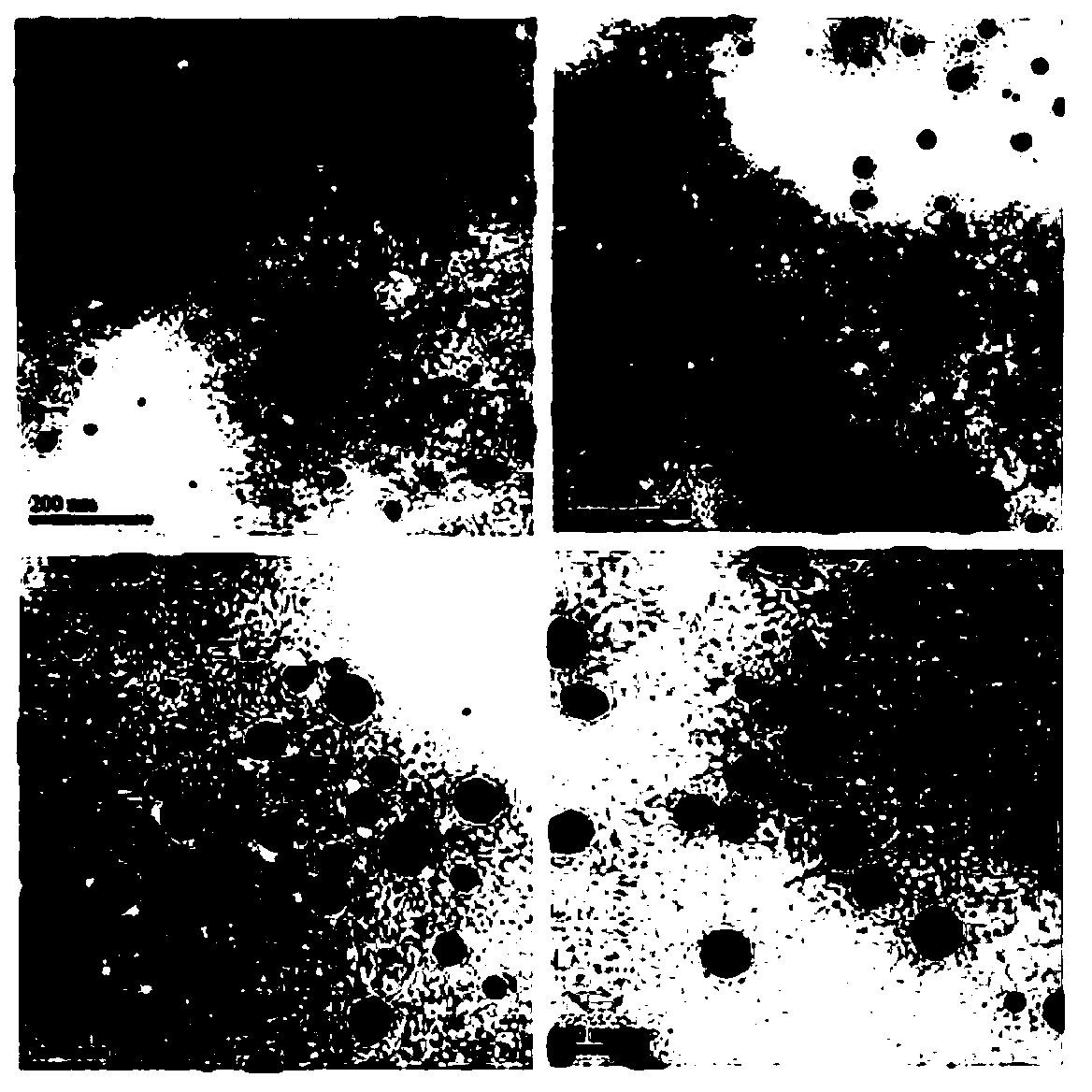

[0018] 3. The ultraviolet-visible absorption spectrum (UV-vis) characterization results of the synthesized gold nanoparticles solution are as follows: figure 2 shown. Transmission electron microscopy (TEM) characterization results are as follows image 3 shown.

Embodiment 2

[0020] 1. the steps of this process method and embodiment one are substantially the same, and the difference is that the control synthesis temperature is room temperature (25 o C). The specific method is to quickly add 1 mL of fruit juice to 20 mL of 0.01% chloroauric acid solution at room temperature, and stop the stirring reaction after stirring for about 3 hours. The reaction obtains a spherical gold nanomaterial with a particle size similar to that of Example 1 and a more dispersed particle size.

[0021] 2. The characterization results of ultraviolet-visible absorption spectrum (UV?vis) are as follows: Figure 4 shown. Transmission electron microscopy (TEM) characterization results are as follows Figure 5 shown.

Embodiment 3

[0023] The steps of this process method and embodiment one are substantially the same, except that the amount of kiwi fruit juice controlled in the nano-golden green process is 2mL. The specific method is to quickly add 2 mL of fruit juice to 20 mL of 0.01% chloroauric acid solution in a boiling water bath, and stop the stirring reaction after about 30 minutes of reaction. The reaction obtains a spherical gold nanomaterial with a particle size distribution similar to that of Example 1 and a larger particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com