Preparation method for low-carbon aluminum-silicon-carbide carbon brick

A technology of silicon carbide carbon bricks and alumina, which is applied in the field of refractory materials, can solve the problems of increased energy consumption, increased heat loss, and large temperature drop of molten iron, and achieves good performance, reduced use, and reduced thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

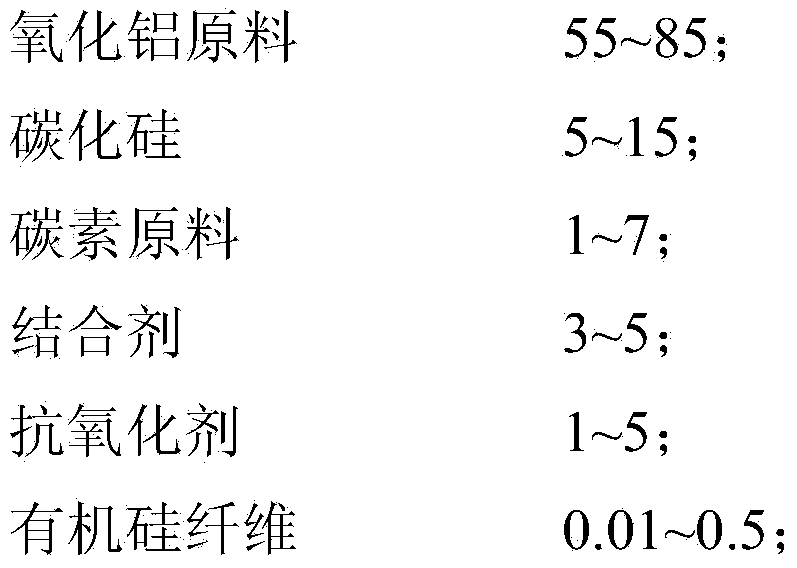

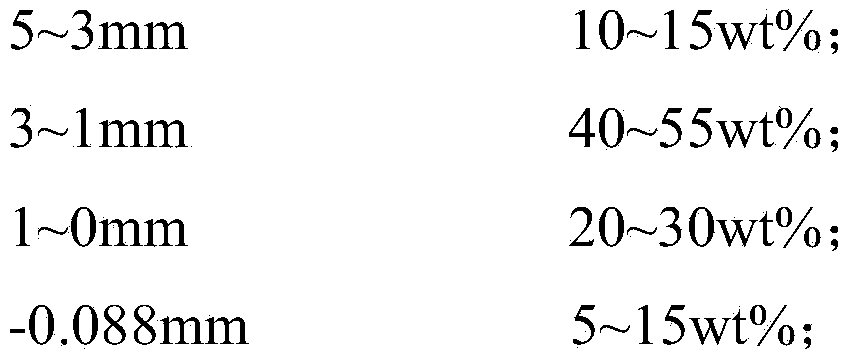

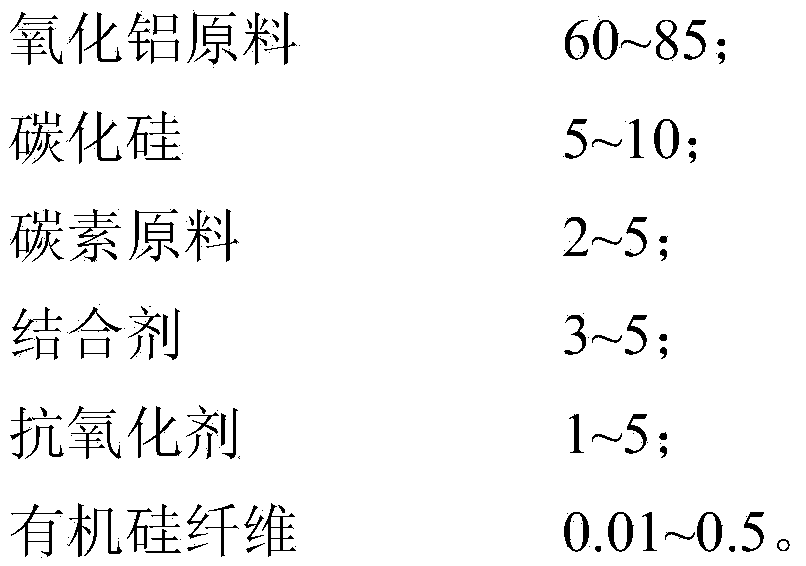

Method used

Image

Examples

Embodiment 1~2 and comparative example 1~2

[0040] The preparation method of the aluminum silicon carbide carbon bricks in Examples 1-2 and Comparative Examples 1-2 is as follows:

[0041] (1) Mix and stir the particles with a particle size of 1 mm or more in the raw material of aluminum silicon carbide carbon bricks and organic silicon fibers for 2 minutes;

[0042] (2) Mix the mixture obtained in step (1) with the phenolic resin and stir for 5 minutes;

[0043] (3) Mix the mixture mixed with phenolic resin and graphite in step (2) and stir for 10 minutes;

[0044] (4) Mix the mixture mixed with graphite in step (3) with the remaining components and stir for 45 minutes;

[0045] (5) The final product in step (4) is finished at 80MPa, and then dried at 220°C for 48 hours to obtain a low-carbon aluminum silicon carbide carbon brick.

[0046] The compositions in parts by weight of the raw materials in Examples 1-2 and Comparative Examples 1-2 are shown in Table 1, and the particle diameters in Table 1 are all average pa...

Embodiment 1

[0054] The aluminum silicon carbide carbon brick prepared in Example 1 has a carbon content of 6.7%, a thermal conductivity of 5.3W / (m K), and a water-cooled thermal shock stability of 20 times at 1100°C. It is used on a ladle , the temperature of the iron shell of the ladle is 20°C lower than that of Comparative Example 1, the heat preservation effect is better, and the service life is the same as that of Comparative Example 1.

Embodiment 2

[0055] The carbon content of the aluminum silicon carbide carbon brick prepared in Example 2 is 8.2%, the thermal conductivity is 6.2W / (m K), and the number of water-cooled thermal shock stability at 1100°C is 20 times. When in use, the temperature of the iron shell of the mixed iron car is 30°C lower than that of Comparative Example 2, the heat preservation effect is better, and the service life is the same as that of Comparative Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com