Polarizing plate and laminated optical member using photocurable adhesive

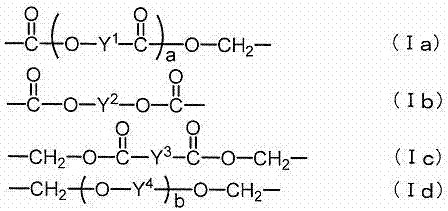

A light-curable, optical component technology, applied in the direction of polarizing elements, optical elements, polyether adhesives, etc., can solve the problems of low moisture permeability, insufficient adhesive strength, high moisture permeability, etc., to achieve excellent coating applicability, The effect of reducing bubble defects and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-3

[0178] (1) Preparation of photocurable adhesive

[0179] According to the proportion shown in Table 1 (the unit is part), the above-mentioned photocation curable components and photocation polymerization initiator were mixed, and then defoamed to prepare a photocurable adhesive liquid. It should be noted that the photocationic polymerization initiator (b1) was blended in the form of a 50% propylene carbonate solution, and Table 1 indicated its solid content.

[0180] (2) Determination of the viscosity of the adhesive liquid at 25°C

[0181] The viscosity at a temperature of 25° C. was measured for each of the adhesive liquids prepared above using a rotary viscoelasticity measuring device “Physica MCR 301 ” manufactured by Anton Paar. The results are shown in Table 1.

[0182] (3) Solubility of protective film

[0183] A retardation film [trade name "N-TAC KC4FR-1", manufactured by Konika Minolta Opto Co., Ltd.] made of an acetylcellulose-based resin and having a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com