Aerogel material and preparation method thereof

A technology of airgel and carrageenan, applied in chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve problems such as low preparation efficiency, uneven material performance, environment and personnel safety, and achieve high production efficiency and easy Promote and enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

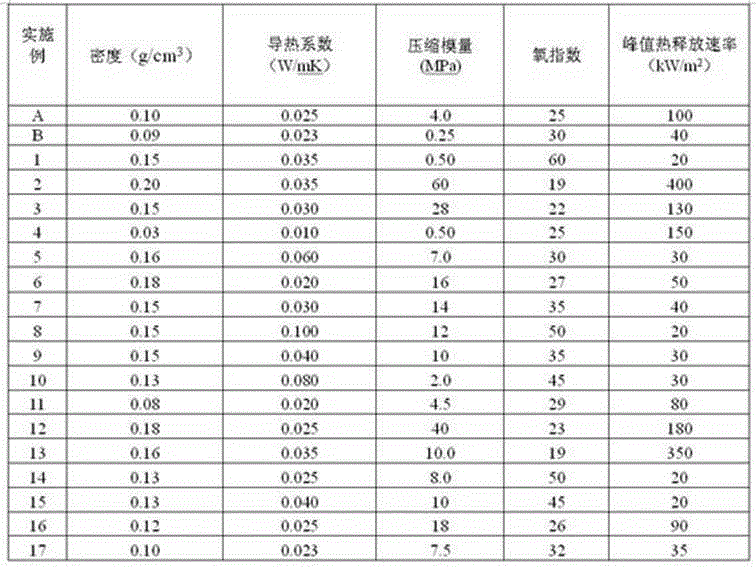

Examples

Embodiment 1

[0022] First, 0.8 g of polyvinyl alcohol (Mw 31,000~50,000, alcoholysis degree 99%) was heated and dissolved in 100 mL of deionized water, 15 g of montmorillonite was added, and then stirred at high speed until it became a uniform colloid. For irradiation crosslinking of kGy, the product was snap-frozen at -78 °C (ethanol bath of dry ice) until ice crystal growth was complete, and vacuum lyophilized at room temperature to complete dryness.

Embodiment 2

[0024] First add 1 g of montmorillonite to 100 mL of deionized water, stir at high speed until a uniform suspension, then heat 20 g of polyvinyl alcohol (Mw 31,000~50,000, alcoholysis degree 99%) to dissolve in the above suspension, in Irradiation crosslinking at a total dose of 200 kGy was performed under gamma rays, and the product was snap-frozen at -78 °C (ethanol bath of dry ice) until ice crystal growth was complete, and vacuum lyophilized at room temperature until complete dryness.

Embodiment 3

[0026] First, 10 g of polyvinyl alcohol (Mw 31,000~50,000, alcoholysis degree 99%) was heated and dissolved in 100 mL of deionized water. After adding 5 g of deionized soil, it was stirred at high speed until it became a uniform colloid. The total dose was 100 under gamma rays. For irradiation crosslinking of kGy, the product was snap-frozen at -78 °C (ethanol bath of dry ice) until ice crystal growth was complete, and vacuum lyophilized at room temperature to complete dryness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com