A kind of bamboo wood composite electrical laminated wood

A technology of electrical laminated wood and bamboo, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc., to achieve the effects of increasing added value, reducing production costs, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Bamboo rotary-cut veneer and fast-growing poplar low-density veneer with a thickness of less than 2mm±0.1mm are used as basic components;

[0020] 2) The peeled bamboo veneer needs to be boiled to remove the hot water extract, and dried to a moisture content of 12-14% to avoid cracking during handling; the double-sided coating of poplar veneer has a solid content of 30%, a pH value of 7.5, and a molecular weight of 400 The following low molecular weight phenolic resin, double-sided glue amount 300g / m 2 ;Dry the dipped veneer to a moisture content of 6-10%;

[0021] 3) Dried moso bamboo veneer and fast-growing poplar low-density veneer coated with low-molecular-weight phenolic resin, and then applied polyvinyl butyral modified phenolic resin, and the double-sided glue amount is 300g / m 2 , after sizing, dry to a moisture content of 6-10%;

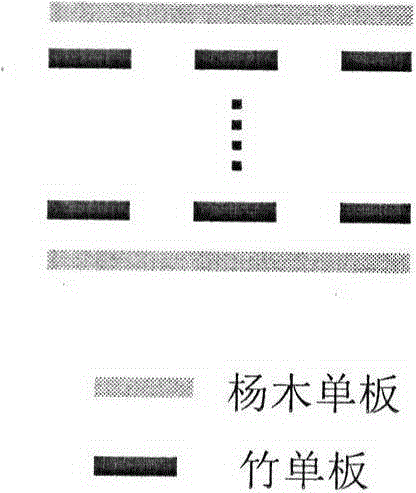

[0022] 4) The blank assembly structure is adjusted according to the performance requirements, usually the bamboo rotary-cut vene...

Embodiment 2

[0030] Step 1) adopting bamboo rotary-cut veneer and fast-growing poplar low-density veneer with a thickness less than 2mm±0.1mm as basic constituent units;

[0031] Step 2) same as above example 2);

[0032] Step 3) Bamboo veneer is coated with polyvinyl butyral modified phenolic resin, double-sided sizing amount 350g / m 2 , after sizing, dry to a moisture content of 6-10%;

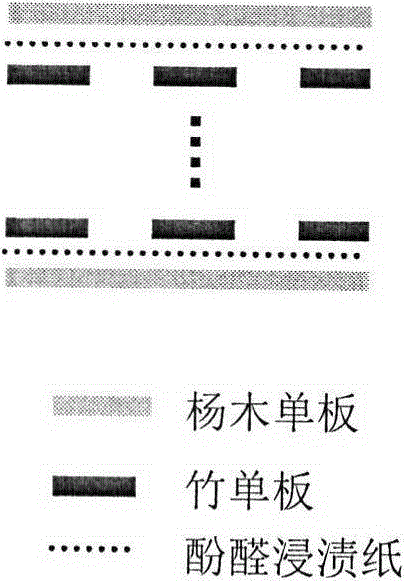

[0033] Step 4) The bamboo veneer, 120 grams of phenolic resin impregnated paper, and fast-growing poplar low-density veneer are assembled symmetrically, as shown in Figure 2.

[0034] Step 5) Hot-press the above slab at 150°C±5°C, pressure 7.0-8.0MPa, time: 1.2-1.5min / mm into a plate, cool the plate surface to below 50°C, and unload the product.

Embodiment 3

[0036] Step 1) adopting bamboo rotary-cut veneer and fast-growing poplar low-density veneer with a thickness less than 2mm±0.1mm as basic constituent units;

[0037] Step 2) same as above example 2);

[0038] Step 3) Coat the peeled bamboo veneer with polyvinyl butyral resin, double-sided sizing amount 330g / m 2 , after sizing, dry to a moisture content of 6-10%;

[0039] Step 4) Assemble the bamboo rotary-cut veneer symmetrically with 120 grams of phenolic resin impregnated paper and fast-growing poplar low-density veneer, as shown in Figure 2.

[0040] Step 5) Hot press the above slab at 150°C±5°C, pressure 8.0-10.0MPa, time: 1.2-1.5min / mm into a plate, cool the plate surface to below 40°C and unload the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com