Comprehensive treatment method of dry spinning spandex waste

A comprehensive treatment, spandex waste silk technology, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of unstable quality of polytetrahydrofuran ether, unable to succeed in large-scale production, etc., to achieve great social and economic benefits , small investment, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

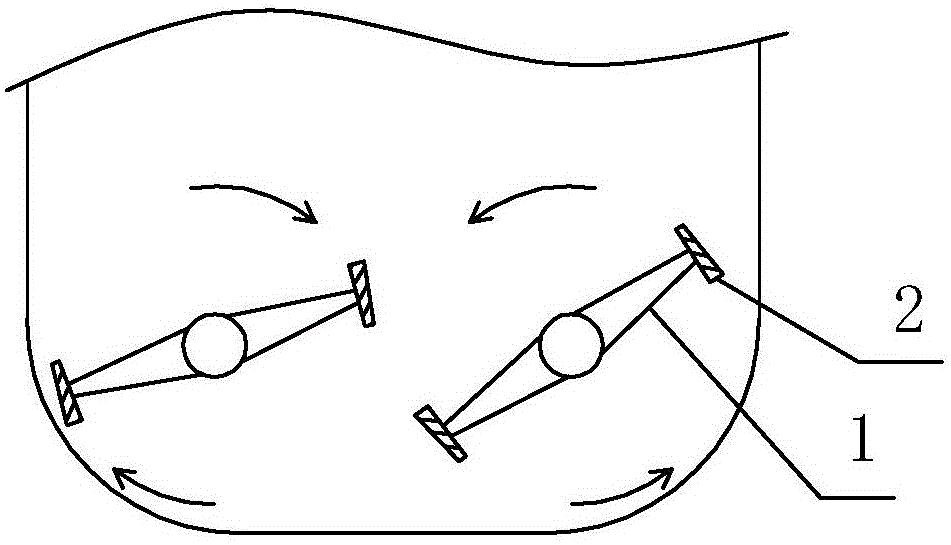

Image

Examples

Embodiment Construction

[0035] A comprehensive treatment method for dry spinning spandex waste, said dry spinning spandex waste refers to dry spinning spandex waste silk, dry spinning spandex waste slurry and dry spinning spandex waste rubber block, the dry spinning spandex The comprehensive treatment method of waste includes the following steps:

[0036] (1) Broken:

[0037] ① Crushing of spandex waste silk by dry spinning method: Put the waste silk into the crusher to obtain shredded waste silk with a length of 2-3cm for later use.

[0038] ②Crushing of spandex waste rubber blocks by dry spinning method: first replace the DMAC (N,N-dimethylacetamide) in the waste rubber blocks (the waste rubber blocks can be soaked in a clear water pool or low-concentration DMAC), so that After the mass concentration of DMAC in the waste rubber block is lower than 5%, put it into the rotary dryer and dry it at 100-105°C until the moisture content is lower than 3%, then put the waste rubber block into the crusher f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com