Humic acid compound fertilizer prepared by peat fermentation and preparation method thereof

A compound fertilizer and humic acid technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of slow fertilizer efficiency, incomplete fermentation, and inability to replenish nutrients in time, and achieve the effect of enhancing absorption efficiency and reducing fertilizer loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

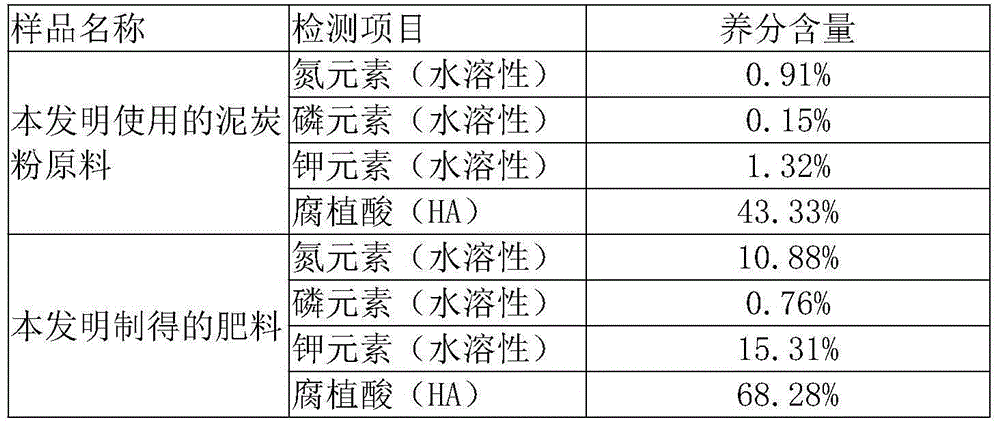

[0056] The preparation of the humic acid compound fertilizer prepared by embodiment 1 peat fermentation

[0057] The preparation steps are divided into three steps: peat fermentation, fermentation chelation and emulsification reaction;

[0058] (1) Peat fermentation

[0059]Crush the peat powder containing 40-45% humic acid to below 100 mesh, add molasses according to the mass ratio of peat:molasses = 100:1, add the mixed bacterial solution until the water content of the mixture is 80%, at 27-33°C Ferment for 5. days to get fermented peat;

[0060] (2) Chelation reaction

[0061] In the reaction kettle, add plant ash and slaked lime into deionized water and stir thoroughly. After 1 hour, add seaweed essence extracted by alkali method, stir thoroughly for 30 minutes, then add fermented peat, and fully react at a temperature of 70°C until pH=6.0 ~7.2, the reaction stops, take the supernatant; the mass ratio of plant ash, slaked lime and deionized water is 10:4:49;

[0062] (...

Embodiment 2

[0085] The preparation of the humic acid compound fertilizer prepared by embodiment 2 peat fermentation

[0086] The preparation steps are divided into three steps: peat fermentation, fermentation chelation and emulsification reaction;

[0087] (1) Peat fermentation

[0088] Crush the peat powder containing 40-45wt% humic acid to less than 100 mesh, add molasses according to the mass ratio of peat:molasses=100:1, insert the mixed bacterial liquid until the water content of the mixture is 90wt%, and ferment at .33°C 5. Days to get fermented peat;

[0089] (2) Chelation reaction

[0090] In the reaction kettle, add plant ash and slaked lime into deionized water and stir thoroughly. After 1 hour, add seaweed essence extracted by alkali method, stir thoroughly for 30 minutes, then add fermented peat, and fully react at a temperature of 60°C until pH=6.0~ 7.2, stop the reaction, take the supernatant; the mass ratio of plant ash, slaked lime and deionized water is 15:2:40;

[00...

Embodiment 3

[0114] The preparation of the humic acid compound fertilizer prepared by embodiment 3 peat fermentation

[0115] The preparation steps are divided into three steps: peat fermentation, fermentation chelation and emulsification reaction;

[0116] (1) Peat fermentation

[0117] Grind the peat powder containing 40-45wt% humic acid to below 100 mesh, add molasses according to the mass ratio of peat:molasses=100:1, insert the mixed bacterial liquid until the water content of the mixture is 85wt%, and ferment at 30°C for 5 God, fermented peat;

[0118] (2) Chelation reaction

[0119] In the reaction kettle, add plant ash and slaked lime to deionized water in turn and stir thoroughly. After 1 hour, add seaweed essence extracted by alkali method, stir thoroughly for 30 minutes, then add fermented peat, and fully react at a temperature of 60°C to 70°C. =6.0~7.2, the reaction stops, take the supernatant; the mass ratio of plant ash, slaked lime and deionized water is 13:3:45;

[0120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com