Preparation method of heparin lithium

A technology of heparin lithium and heparin sodium, which is applied in the chemical industry, can solve the problems of high raw material cost, poor operability, and high price of heparin lithium, and achieve the effects of reducing production costs, wide sources of raw materials, and low preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

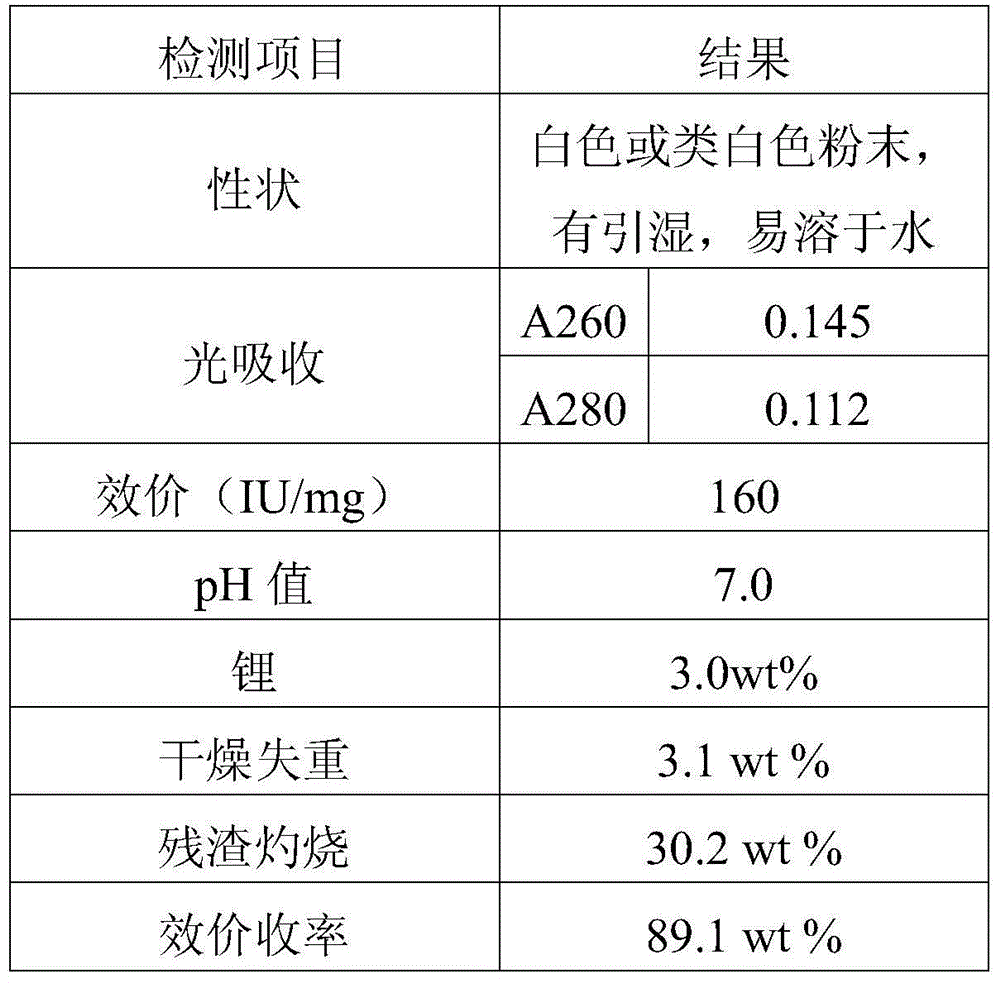

Image

Examples

Embodiment 1

[0031] A preparation method of lithium heparin is as follows:

[0032] (1) Adsorption:

[0033] Weigh 500kg of porcine small intestine mucosa and place it in a reaction pot, add water to dilute, adjust the pH value to 9.0-9.5 with 30% sodium hydroxide solution, heat to boiling, keep for 15 minutes, cool down to 35°C, and at the same time, siphon the filtrate into the reaction tank, add 10% D204 resin resin, heat preservation and stirring for 10h;

[0034] (2) Washing:

[0035] Take the adsorbed liquid in step (1) and let it stand for 30 minutes, then filter it, collect the resin, rinse the resin with water, and drain it for later use;

[0036] (3) Elution:

[0037] Take the solid in step (2) and add 1mol / L sodium chloride to wash for 1~3h, after draining, add 4mol / L sodium chloride 1~3 times, stir and elute for 5h, drain and then elute twice, The amount of 4mol / L sodium chloride solution is halved each time, the elution time is 2h and 1h respectively, and all eluents are c...

Embodiment 2

[0048] A preparation method of lithium heparin is as follows:

[0049] (1) Adsorption:

[0050] Weigh 500kg of porcine small intestinal mucosa and put it in a reaction pot, add water to dilute, adjust the pH value to 9.0-9.5 with 30% sodium hydroxide solution, heat to boiling, keep for 15min, cool down to 35°C, and at the same time, siphon the filtrate into the reaction tank, add 10% D204 resin resin, heat preservation and stirring for 10h;

[0051] (2) Washing:

[0052] Take the adsorbed liquid in step (1) and let it stand for 30 minutes, then filter it, collect the resin, rinse the resin with water, and drain it for later use;

[0053] (3) Elution:

[0054] Take the solid in step (2) and add 1mol / L sodium chloride to wash for 1 to 3 hours. After draining, add 1 to 3 times the amount of 4mol / L sodium chloride, stir and elute for 5 hours, and then elute twice after draining. The amount of 4mol / L sodium chloride solution is halved each time, the elution time is 2h and 1h re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com