Self-lubricating wear-resistant polyether-ether-ketone slip sheet and formula and preparation method thereof

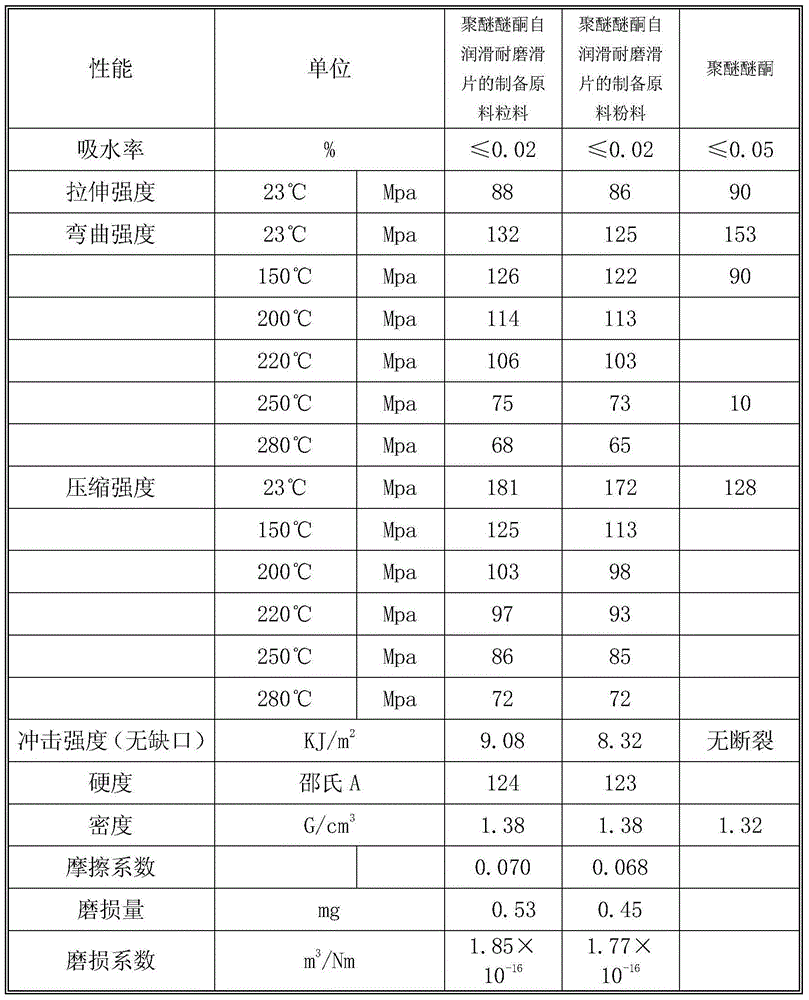

A technology of wear-resistant polyether and polyetheretherketone, which is applied in the field of high-performance polymer materials, can solve problems such as glass transition temperature load thermal deformation temperature is not high enough, friction force and coefficient of friction are large, thermoplastic deformation and flow, etc. Achieve the effects of increasing the contact area, improving self-lubrication, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

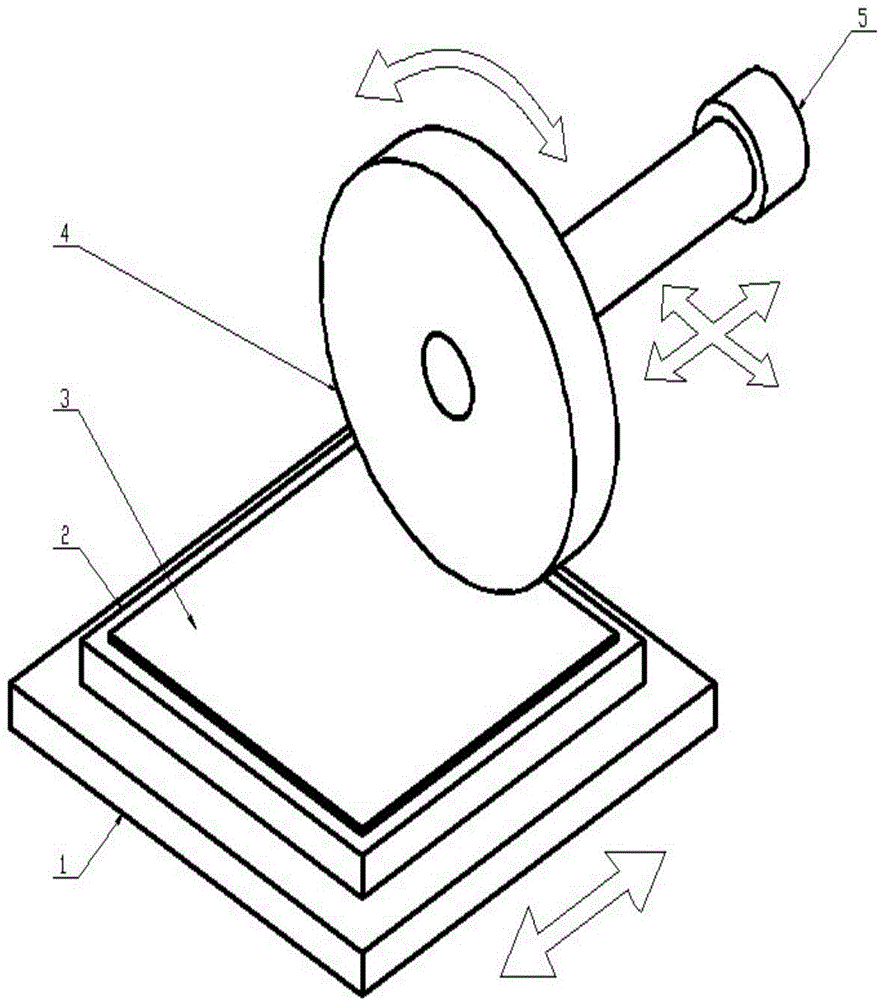

Method used

Image

Examples

Embodiment 1

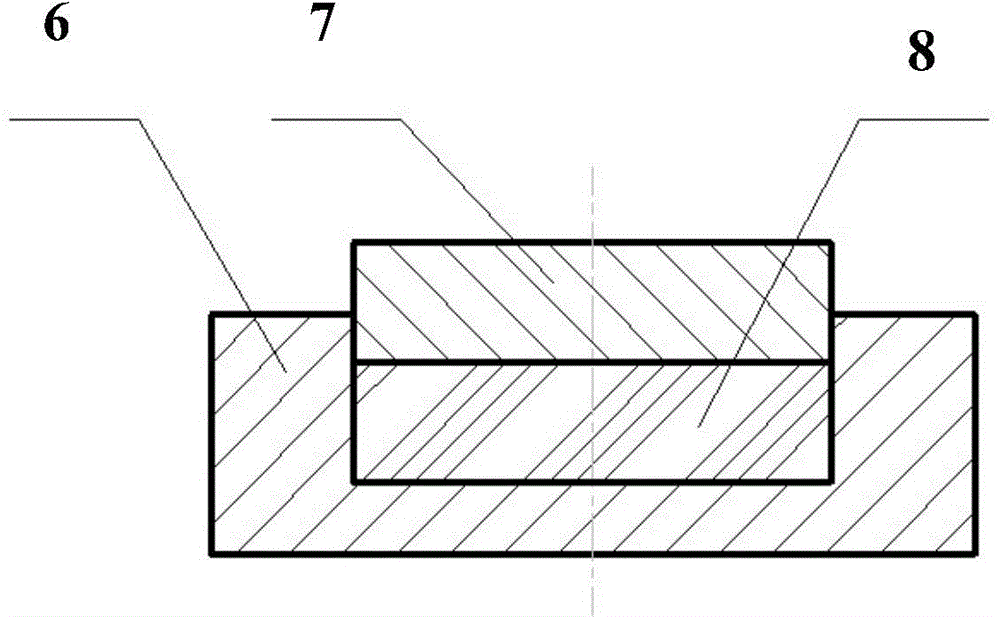

[0031] The raw materials used are 80 parts of polyether ether ketone, 15 parts of polytetrafluoroethylene, MoS 2 2 parts and 3 parts of graphite. After molded by method 1, a wear-resistant sliding piece of 160×150×4 (mm) was processed by a grinder. The tribological properties of the made sliding piece were investigated on a friction and wear testing machine, and the sliding speed was 1m / s, the sliding time is 3h, and the wear amount is 0.9g.

Embodiment 2

[0033] The raw materials are 70 parts of polyether ether ketone, 25 parts of polytetrafluoroethylene, MoS 2 2 parts and 3 parts of graphite. After injection molding by method 2, a wear-resistant sliding piece of 160×150×4 (mm) was processed on a grinding machine. The tribological properties of the made sliding piece were investigated on a friction and wear testing machine, and the sliding speed was 1m / s, the sliding time is 3h, and the wear amount is 1.0g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com