Supermolecule corrosion inhibitor for copper and copper alloy and superfine grinding preparation method thereof

A corrosion inhibitor and supramolecular technology, which is applied in the field of copper and its alloy corrosion inhibitor and its ultra-fine grinding preparation, can solve the problems of copper and its alloy corrosion and poor anti-corrosion measures, and achieve a small amount of use , Excellent anti-corrosion effect, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

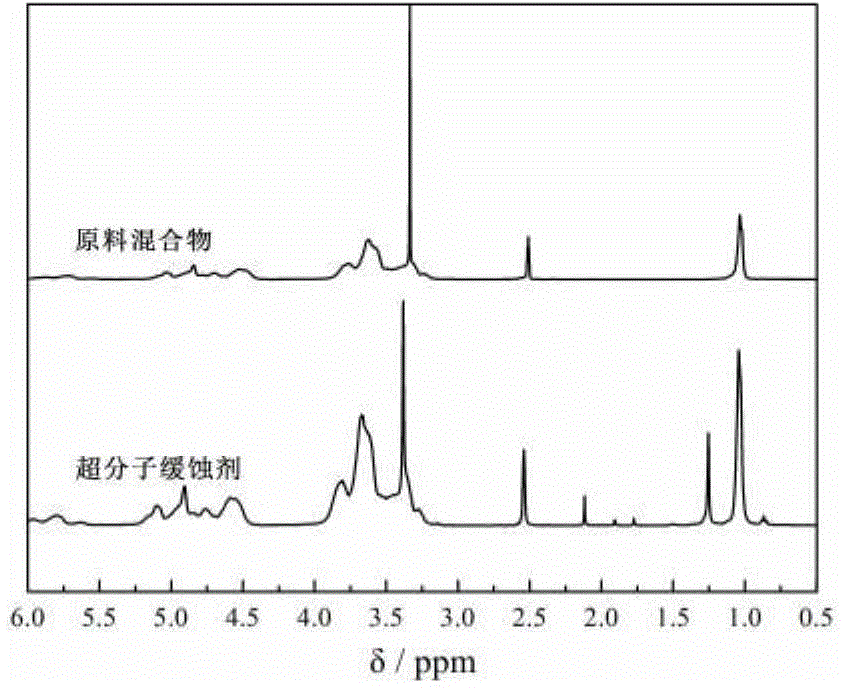

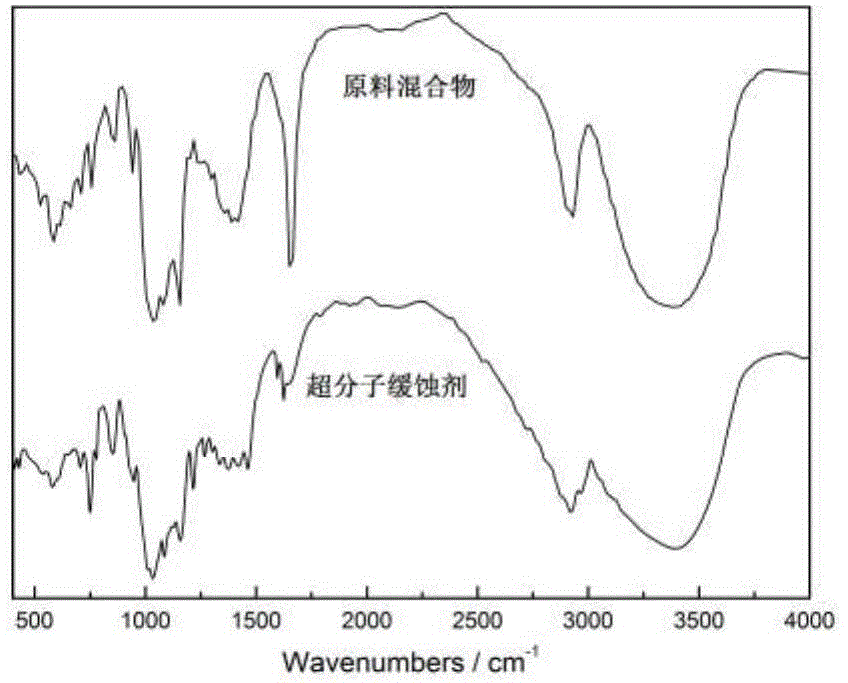

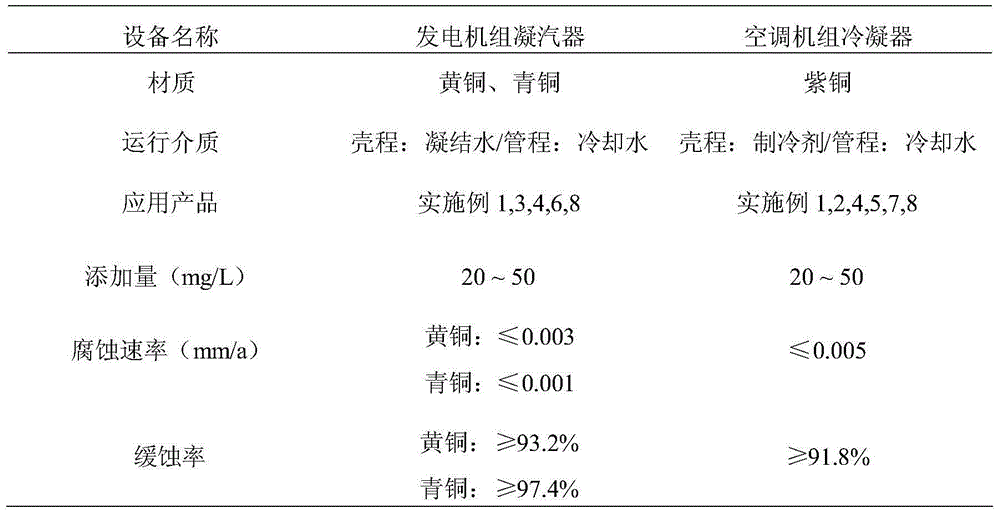

[0022] Mix 5g of methyl-β-cyclodextrin and 1ml of water into a paste and transfer it into a dispersing sand mill and mix evenly at a grinding speed of 600r / min; then add 1.2g of benzothiazole to the dispersing sand mill, Continue to grind at a grinding rate of 600r / min for 30min; then slowly add 2.5mL of ethylene glycol dropwise, adjust the grinding rate to 2000r / min, and continue grinding for 40min; finally, vacuum dry and remove water at 80°C to obtain copper and its A supramolecular corrosion inhibitor for alloys, the corrosion inhibitor is a combination of methyl-β-cyclodextrin with hydrophobic cavity and benzothiazole induced by ethylene glycol and combined with weak interactions between molecules. Inclusion compound of molecular structure. The application effect is shown in Table 1.

Embodiment 2

[0024] Mix 10g of hydroxypropyl-β-cyclodextrin and 5ml of water into a paste, then transfer it into a dispersing sand mill and mix evenly at a grinding speed of 800r / min; then add 2.5g of benzotri For nitrogen azole, continue to grind at a grinding rate of 800r / min for 15min; then slowly add 3mL of cyclohexanol dropwise, adjust the grinding rate to 4000r / min, and continue grinding for 45min; finally, vacuum dry and remove water at 70°C to obtain copper Supramolecular corrosion inhibitor and its alloy, the corrosion inhibitor is a combination of hydroxypropyl-β-cyclodextrin with a hydrophobic cavity and benzotriazole induced by cyclohexanol and through weak intermolecular interactions And the formation of clathrates with supramolecular structure. The application effect is shown in Table 1.

Embodiment 3

[0026] Mix 10g of carboxymethyl-β-cyclodextrin and 6ml of water into a paste, transfer it to a dispersing sand mill and mix evenly at a grinding speed of 1000r / min; then add 4.2g of 2-mercaptobenzene to the dispersing sand mill And thiazole, continue to grind at a grinding rate of 1000r / min for 25min; then slowly add 2mL of dicyclohexylamine dropwise, adjust the grinding rate to 5000r / min, and continue grinding for 30min; finally, vacuum dry and remove water at 80°C to obtain Supramolecular corrosion inhibitor for copper and its alloys, the corrosion inhibitor is carboxymethyl-β-cyclodextrin with hydrophobic cavity and 2-mercaptobenzothiazole induced by dicyclohexylamine and passed through the weak intermolecular Inclusion complex with supramolecular structure formed by interaction and combination. The application effect is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com