Cooling method of compressed air in methanol air separation plant

A technology of compressed air and cooling method, which is applied in the direction of water shower cooler, heat exchange equipment, damage protection, etc., and can solve problems such as pulverization, molecular sieve carrying water, heat exchanger blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

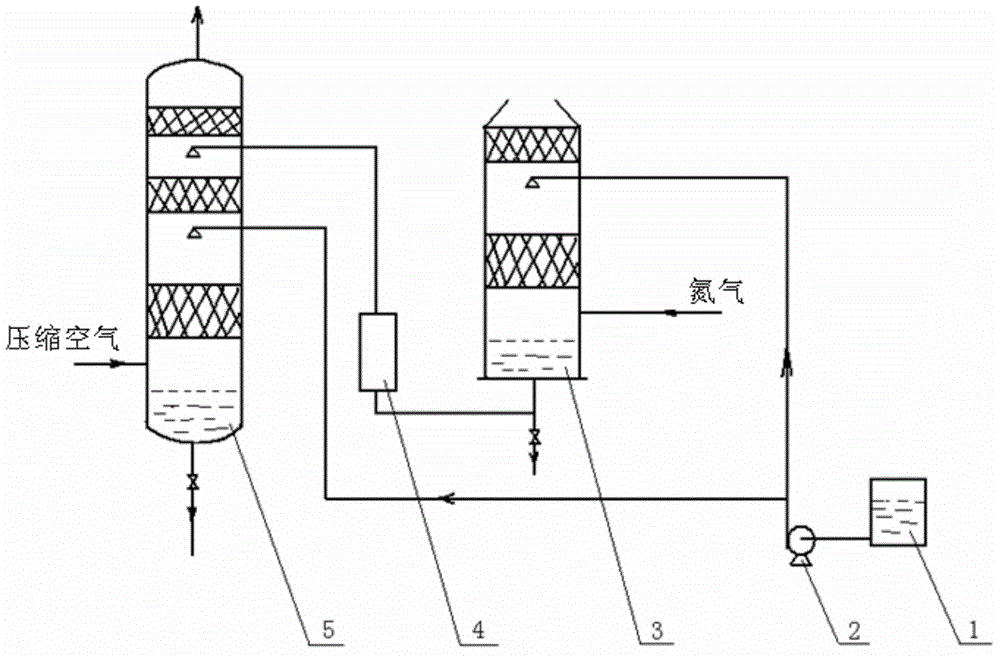

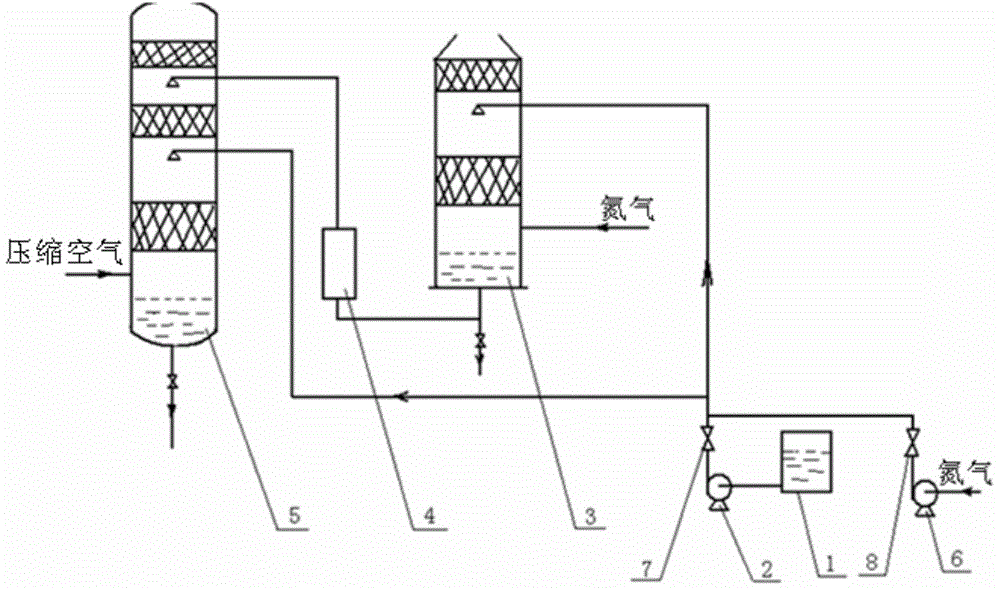

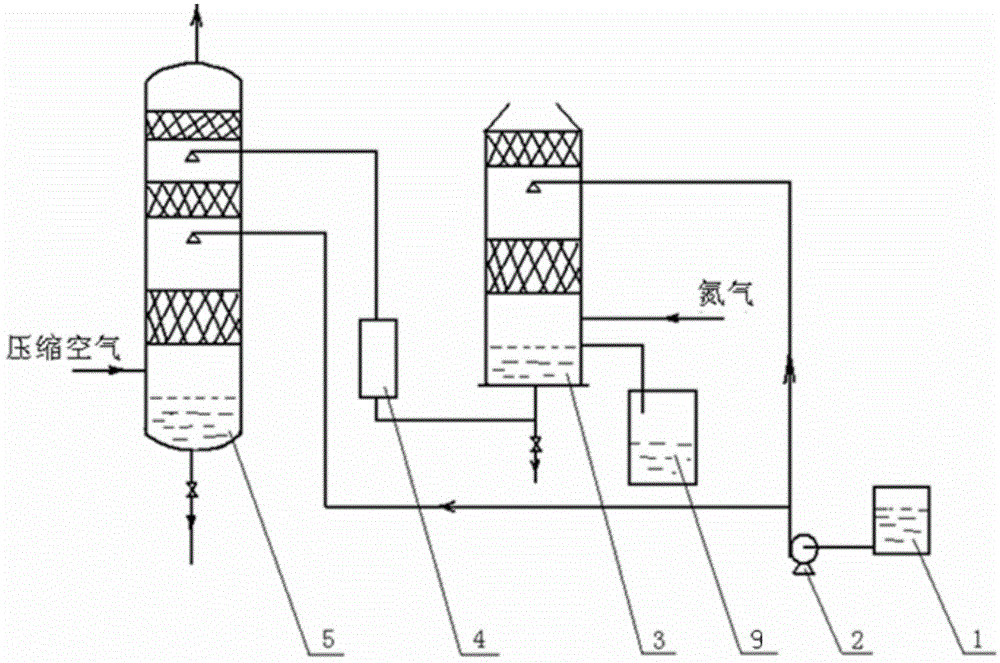

[0021] Specific implementation mode one: (see attached figure 1 ) The method for cooling the compressed air in the methanol air separation workshop of the present embodiment includes the following steps:

[0022] 1. Set up a cooling system: the system includes a clean water tank 1, a clean water pump 2, a water cooling tower 3, a chilled water pump 4 and an air cooling tower 5,

[0023] The side wall of the water cooling tower 3 is provided with a water inlet and a nitrogen inlet successively from top to bottom, and the bottom of the water cooling tower 3 is provided with a water outlet; the top of the water cooling tower 3 has an air outlet;

[0024] The side wall of the air cooling tower 5 is sequentially provided with a chilled water inlet, a cooling water inlet, and an air inlet from top to bottom;

[0025] The clean water pool 1 is connected with the clean water pump 2, and the outlet of the clean water pump 2 is provided with two pipes, one pipe is connected with the wa...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the flow rate of the water entering the water cooling tower 3 is 18~20m 3 / h. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the flow rate of the water entering the water cooling tower 3 is 19m 3 / h. Others are the same as the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap