A kind of preparation method of porous crystalline tio2 photoanode

A technology of photoanode and crystalline state, which is applied in the direction of photosensitive equipment, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of complex preparation process and harsh experimental conditions, and achieve simple preparation process, improve charge collection efficiency, The effect of improving the diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

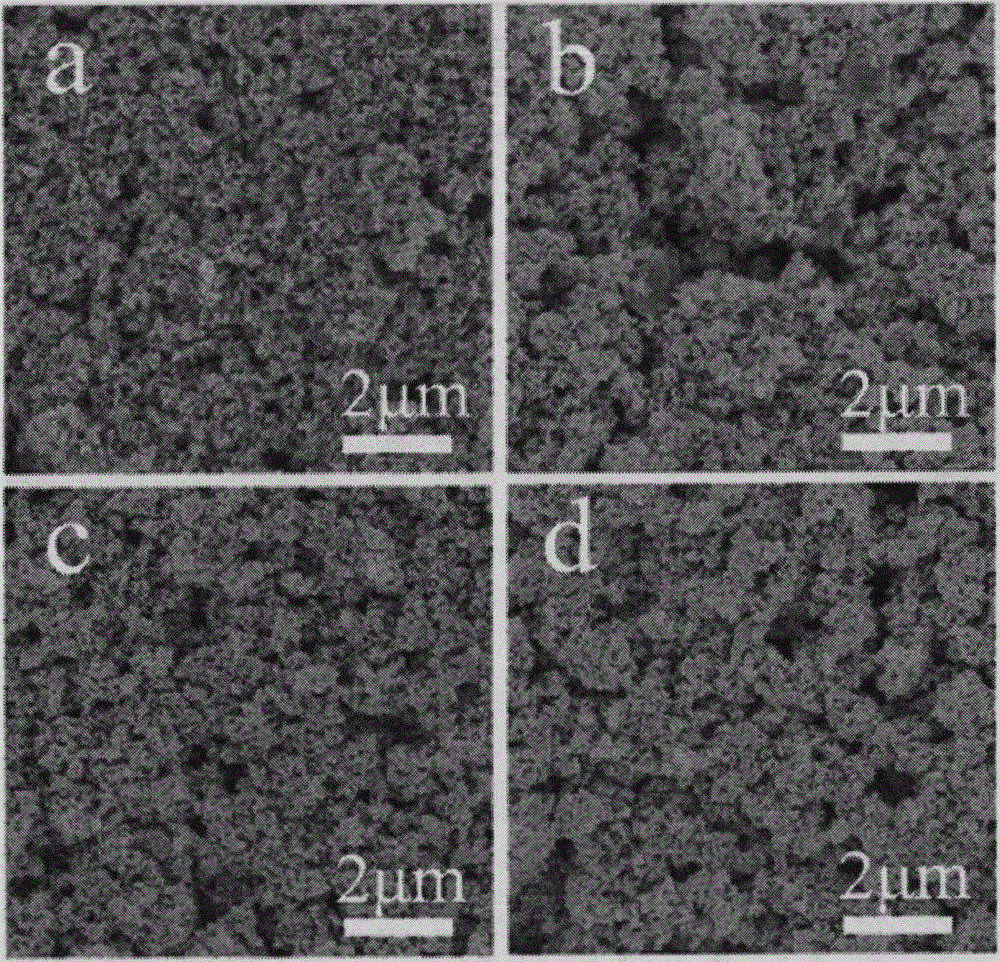

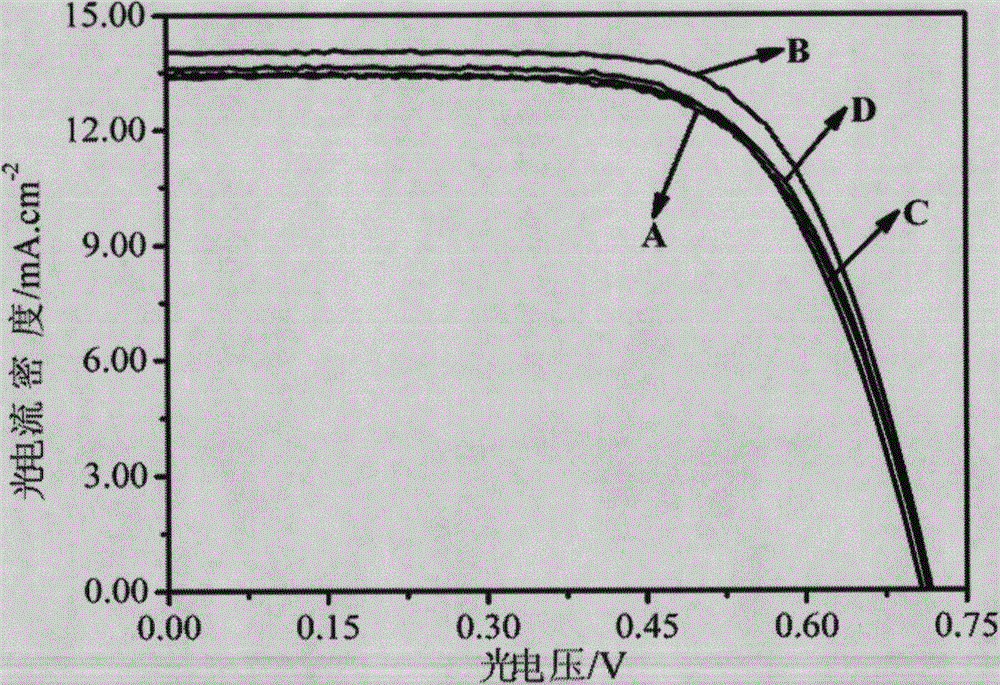

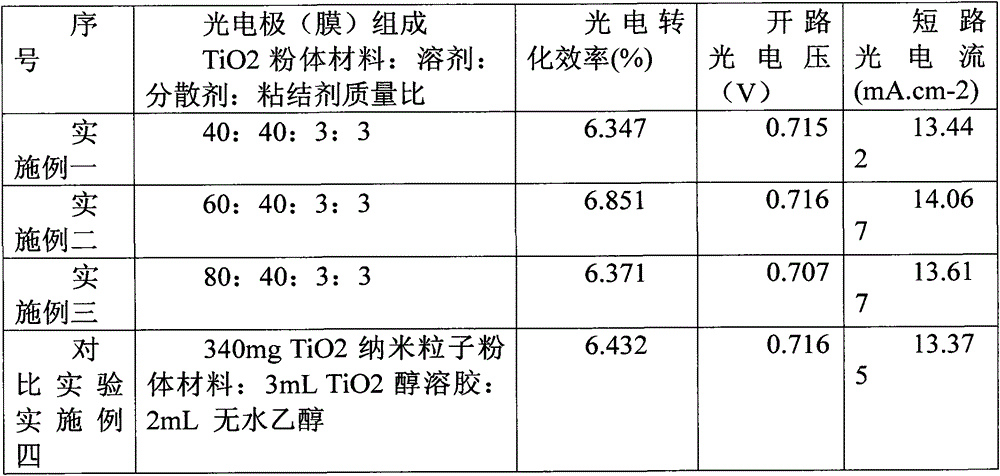

[0023] Weigh commercial TiO2 nanoparticle powder material, camphene solvent, Texaphor3250 dispersant and polystyrene binder in a mass ratio of 40:40:3:3, then stir and mix the above-mentioned weighed reagents for 30min to obtain a mixed reagent ; 2. Ball mill the mixture reagent in step 1 at a temperature of 80° C. for 60 hours to obtain a slurry; 3. Stir the slurry in step 2 at 60° C. in an external water bath for 1-3 hours, and then scrape-coat it on a layer containing a single layer of crystalline TiO2 On the conductive glass of the nanoparticle film; 4. Put the photoanode prepared in step 3 into the muffle furnace, first raise the temperature to 100°C at a speed of 1°C / min and keep it for 30min, and then heat up to 100°C at a speed of 2°C / min. Keep at 450°C for 30 minutes to obtain a porous crystalline TiO2 photoanode, and the total thickness of the film is 10 μm.

[0024] Preparation of Pt counter electrode:

[0025] Use a micro-syringe to draw 20 μL of anhydrous isoprop...

Embodiment 2

[0029] The difference between this embodiment and embodiment one is that in step one, the commercial TiO2 nanoparticle powder material, camphene solvent, Texaphor3250 dispersant and polystyrene binder are weighed successively by mass ratio of 60:40:3:3, Others are the same as in Embodiment 1.

Embodiment 3

[0031] The difference between this embodiment and embodiment one is that in the step one, the commercial TiO2 nanoparticle powder material, camphene solvent, Texaphor3250 dispersant and polystyrene binder are weighed successively by mass ratio of 80:40:3:3, Others are the same as in Embodiment 1.

[0032] Comparative Experiment:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com