High-capacity unified power quality conditioner based on chain structure and control method thereof

A technology of power quality and control method, applied in the direction of AC network voltage adjustment, reactive power compensation, multi-phase network asymmetry reduction, etc., can solve the problems of capacitor voltage imbalance, high requirements, small UPQC capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

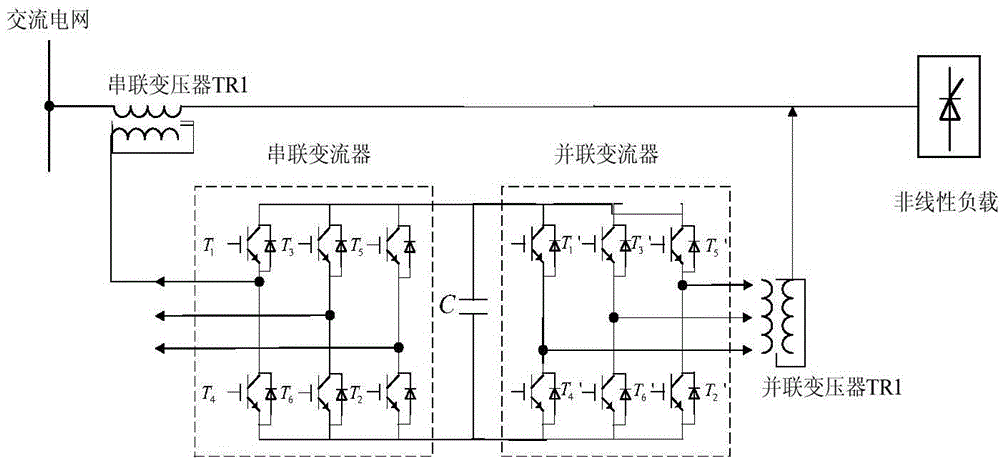

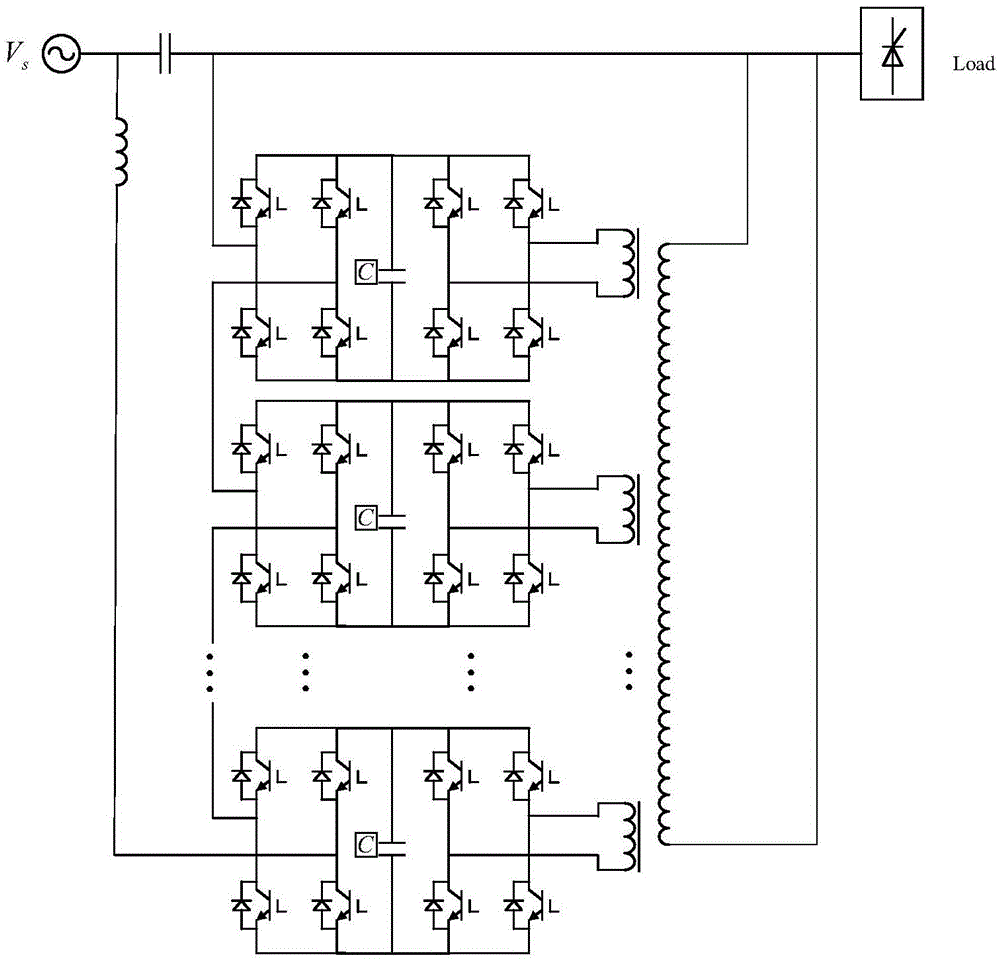

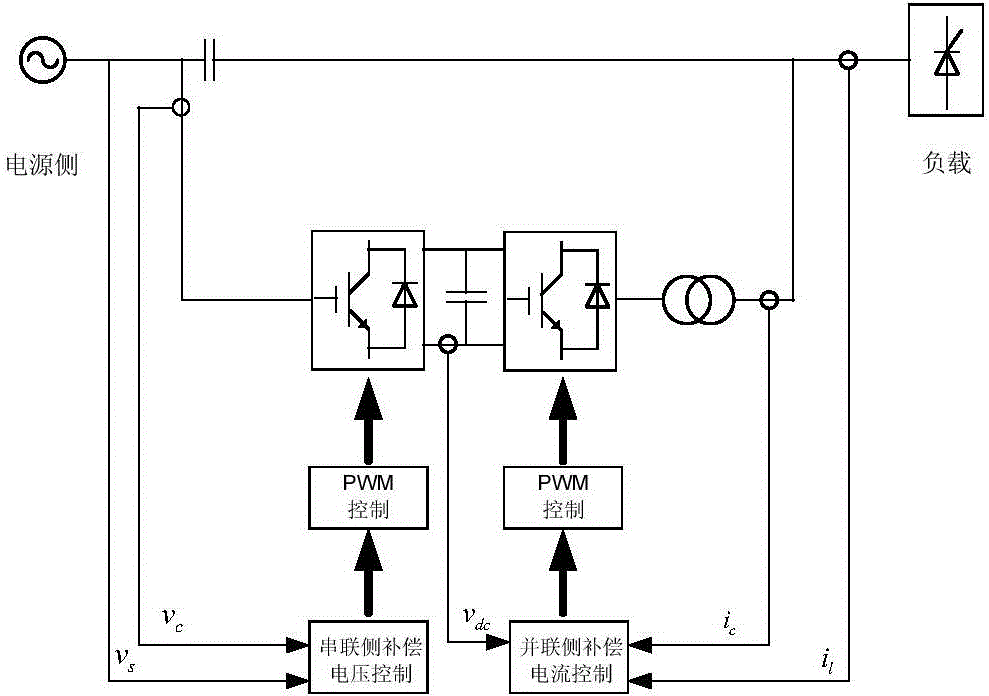

[0031] The chain structure-based large-capacity three-phase three-wire system serial-parallel structure UPQC main loop topology proposed by the present invention is as follows: figure 2As shown, it includes series-connected voltage source converters and parallel-connected voltage source converters connected through the common DC bus. The capacitor is connected to the grid on the AC side (system side or power supply side). The parallel voltage source converter is a single-phase H-bridge structure, which forms a "back-to-back" structure with the H-bridge links on the series side. Each H-bridge link of the parallel voltage source converter is connected to the secondary side of the single-phase multi-winding transformer. On the load side (load side or DC side). The parallel voltage source converter plays the role of volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com