Waterproof tile adhesive material

A technology of tile adhesive and penetrating material, applied in the field of waterproof tile adhesive materials, can solve the problems of weakening the bonding performance of walls and tiles, failing to achieve the waterproof function of buildings, and single function, so as to improve the compactness and waterproof resistance. permeability, improve compaction and waterproof and impermeability, and promote the effect of hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

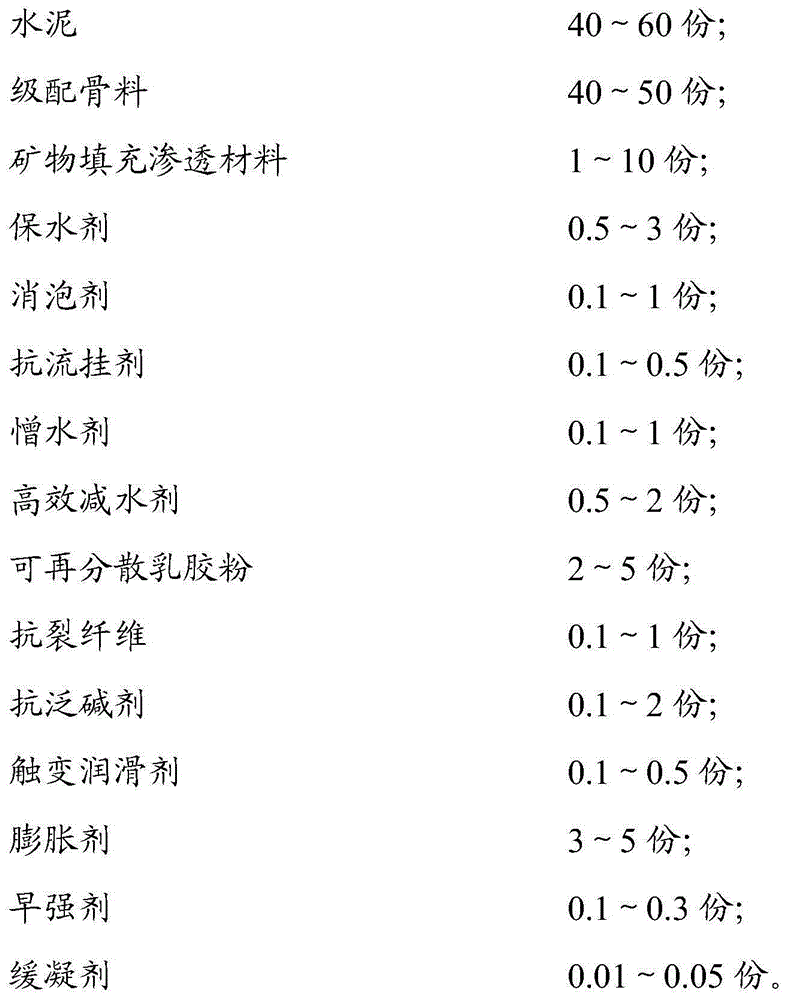

[0041] Example 1——In parts by weight, 40 parts of cement, 40 parts of graded aggregate, 1 part of mineral-filled permeable material, 0.5 part of water-retaining agent, 0.1 part of defoamer, 0.1 part of anti-sagging agent, hydrophobic 0.1 part of superplasticizer, 0.5 part of superplasticizer, 2 parts of redispersible latex powder, 0.1 part of anti-cracking fiber, 0.1 part of anti-efflorescence agent, 0.1 part of thixotropic lubricant, 3 parts of expansion agent, 0.1 part of early strength agent and moderate 0.01 part of coagulant is mixed evenly, and the mass ratio of the above mixture to water is 1:0.2, and then the above materials are stirred with water, and there is no agglomeration after stirring, and the prepared slurry is left for about 5 minutes, and then mixed with a stirrer It can be applied evenly.

Embodiment 2

[0042] Example 2——In parts by weight, 60 parts of cement, 50 parts of graded aggregate, 10 parts of mineral-filled permeable material, 3 parts of water-retaining agent, 1 part of defoamer, 0.5 part of anti-sagging agent, hydrophobic 1 part of superplasticizer, 2 parts of superplasticizer, 5 parts of redispersible latex powder, 1 part of anti-cracking fiber, 2 parts of anti-efflorescence agent, 0.5 part of thixotropic lubricant, 5 parts of expansion agent, 0.3 part of early strength agent and moderate 0.05 parts of coagulant are mixed evenly, and the mass ratio of the above mixture to water is 1:0.3, and then the above materials are stirred with water, stirring evenly without agglomeration, and the prepared slurry is left for about 5 minutes, and then mixed with a stirrer It can be applied evenly.

Embodiment 3

[0043] Example 3—In parts by weight, 50 parts of cement, 45 parts of graded aggregate, 3 parts of mineral-filled permeable material, 1 part of water-retaining agent, 0.5 part of defoamer, 0.2 part of anti-sagging agent, hydrophobic 0.5 parts of superplasticizer, 1.5 parts of superplasticizer, 3.5 parts of redispersible latex powder, 0.6 parts of anti-cracking fiber, 1 part of anti-efflorescence agent, 0.2 parts of thixotropic lubricant, 3.5 parts of expansion agent, 0.2 parts of early strength agent and moderator 0.04 parts of coagulant are mixed evenly, and the mass ratio of the above mixture to water is 1:0.2.5 for configuration, and then the above materials are stirred with water, stirring evenly without agglomeration, and the prepared slurry is placed for about 5 minutes, and then stirred Mix well and start construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com