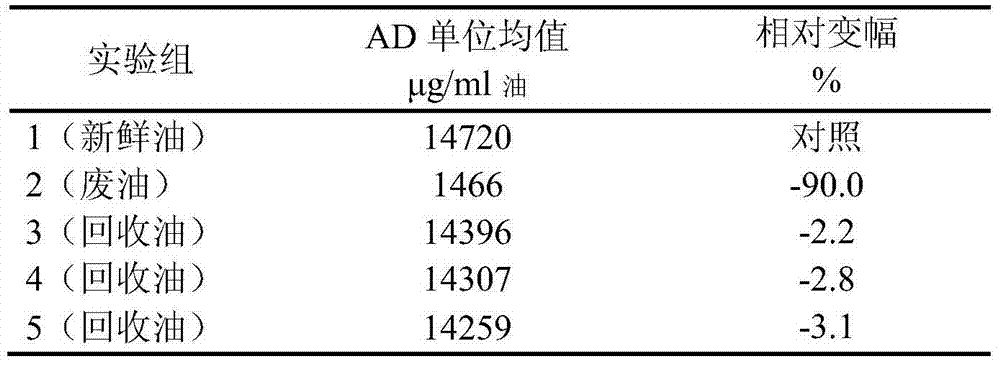

Method for recycling edible oil in androstenedione production process through biotransformation

A technology of androstenedione and biotransformation, applied in the direction of organic chemistry, steroids, etc., can solve the problems of environmental pollution, waste of vegetable oil resources, etc., and achieve the effects of protecting the environment, reducing the heating time, and shortening the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Material source: The biotransformation reaction liquid of androstenedione in the upper section adopts a two-liquid-solid-solid four-phase process, and the obtained biotransformation reaction liquid is a liquid-liquid-solid-solid four-phase system, and the liquid phases are water phase and The oil phase (food grade vegetable oil), the solid phase are the cells and the medium containing the product respectively. The vegetable oil can be corn oil, rapeseed oil, sunflower oil, soybean oil, peanut oil, salad oil, edible blending oil, etc.

[0026] The separation process steps are as follows

[0027] Step 1: Place the liquid-liquid-solid-solid four-phase system in the washing tank and settle naturally. Temperature, 10°C, settling time: about 10 hours.

[0028] Step 2: Open the discharge valve at the bottom of the washing tank, discard the heavy water phase to the three waste collection pool, the liquid-solid-solid three-phase feed liquid left in the washing tank; the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com