CO2 supercritical extraction method for effective components of sonchus arvensis

An effective ingredient and a technology of radicchio, applied in the field of radicchio extraction, can solve the problem that the yield of flavonoids and triterpenoids cannot be guaranteed at the same time, the content of insoluble impurities in supercritical fluid is high, and the active ingredients of medicinal materials are easily destroyed. and other problems, to achieve the effect of good flow and transfer performance, increased extraction capacity, and strong dissolving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

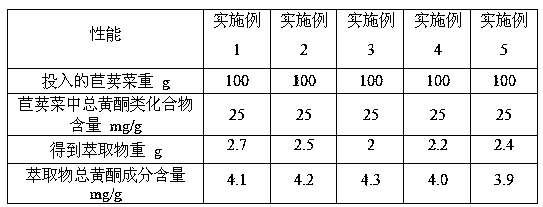

Examples

Embodiment 1

[0021] a) Take 100g of Chinese lettuce medicinal materials and crush them with a crusher, and pass through a 20-mesh sieve;

[0022] b) Soak the broken lettuce in an ethanol-water solution for 2 hours, and the concentration of ethanol in the ethanol-water solution is 30% by volume;

[0023] c) Put the soaked lettuce into the supercritical extraction equipment for CO 2 Supercritical extraction, extraction kettle temperature 60°C, extraction kettle pressure 15Mpa, separation kettle I temperature 65℃, separation kettle I pressure 8Mpa, separation kettle II temperature 35℃, separation kettle II pressure 6Mpa, add 100ml of 30% ethanol as entrainer, The extraction time is 6 hours;

[0024] d) The extracts obtained from the two separation tanks were combined and concentrated at 50° C. under normal pressure for 6 hours to obtain the lettuce extract.

Embodiment 2

[0026] a) Take 100g of Chinese lettuce medicinal materials and crush them with a crusher, and pass through a 10-mesh sieve;

[0027] b) Soak the broken lettuce in an ethanol-water solution for 1 hour, and the concentration of ethanol in the ethanol-water solution is 40% by volume;

[0028] c) Put the soaked lettuce into the supercritical extraction equipment for CO 2 Supercritical extraction, extraction kettle temperature 55°C, extraction kettle pressure 18Mpa, separation kettle I temperature 55°C, separation kettle I pressure 10Mpa, separation kettle II temperature 39°C, separation kettle II pressure 7Mpa, add 100ml of 30% ethanol as entrainer, The extraction time is 6 hours;

[0029] d) Combine the extracts obtained from separation tanks I and II, concentrate at 55° C. under reduced pressure at 0.02 Mpa for 5 hours, and obtain the lettuce extract.

Embodiment 3

[0031] a) Take 100g of Chinese lettuce medicinal materials and crush them with a crusher, and pass through a 10-mesh sieve;

[0032] b) Soak the broken lettuce in an ethanol-water solution for 8 hours, and the concentration of ethanol in the ethanol-water solution is 60% by volume;

[0033] c) Put the soaked lettuce into the supercritical extraction equipment for CO 2 Supercritical extraction, extraction kettle temperature 40°C, extraction kettle pressure 25Mpa, separation kettle I temperature 40°C, separation kettle I pressure 8Mpa, separation kettle II temperature 36°C, separation kettle II pressure 5Mpa, add 100ml of 90% ethanol as entrainer, The extraction time is 1 hour;

[0034] d) Combine the extracts obtained from the separation tanks I and II, and concentrate at 40° C. under normal pressure for 7 hours to obtain the lettuce extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com