Physical strength and flexible helical blade-coupled walnut shell and kernel drum two-way separation equipment

A helical blade, two-way separation technology, used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems of automatic separation, long working cycle, and no pollution of walnut and walnut.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

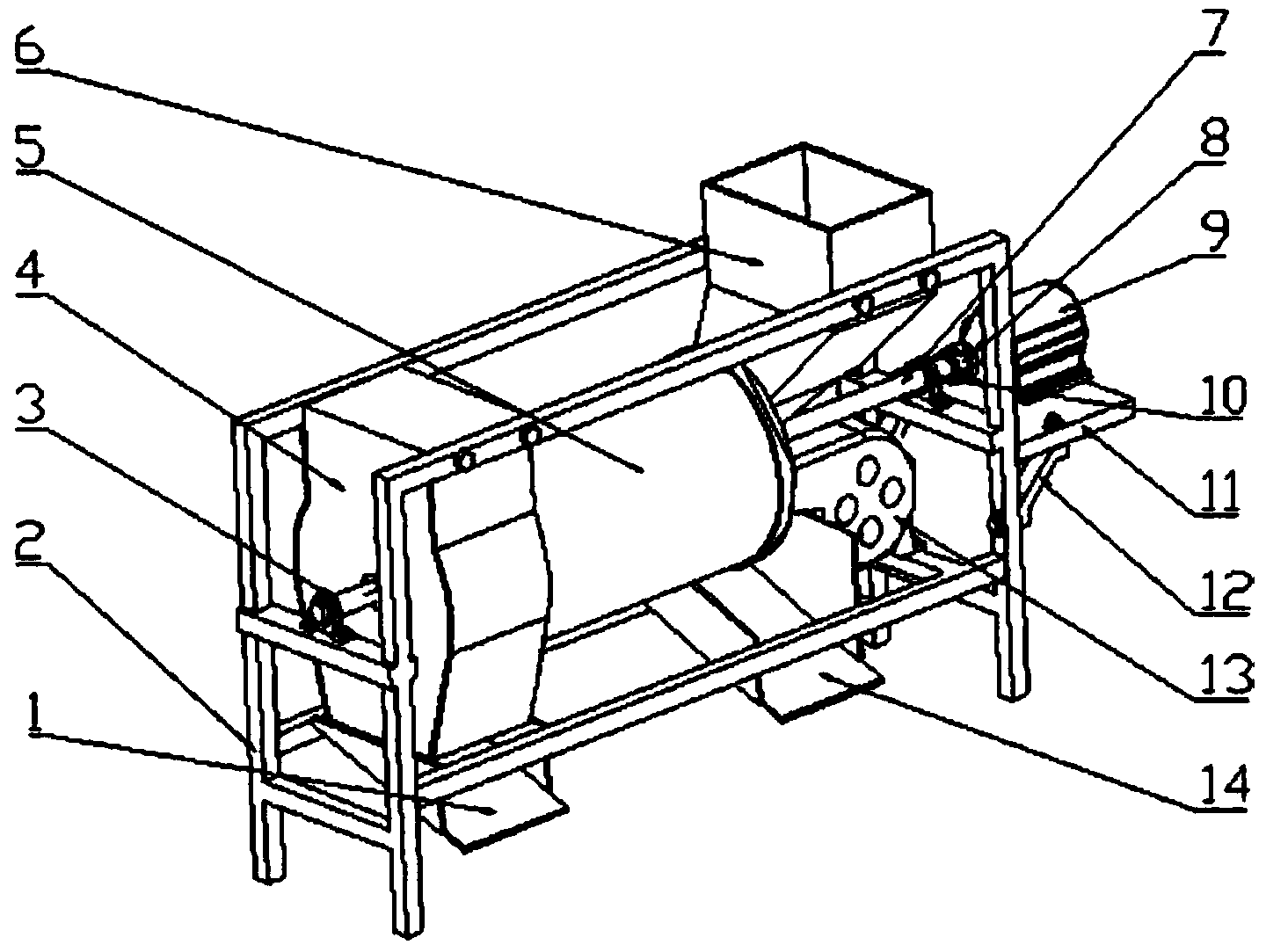

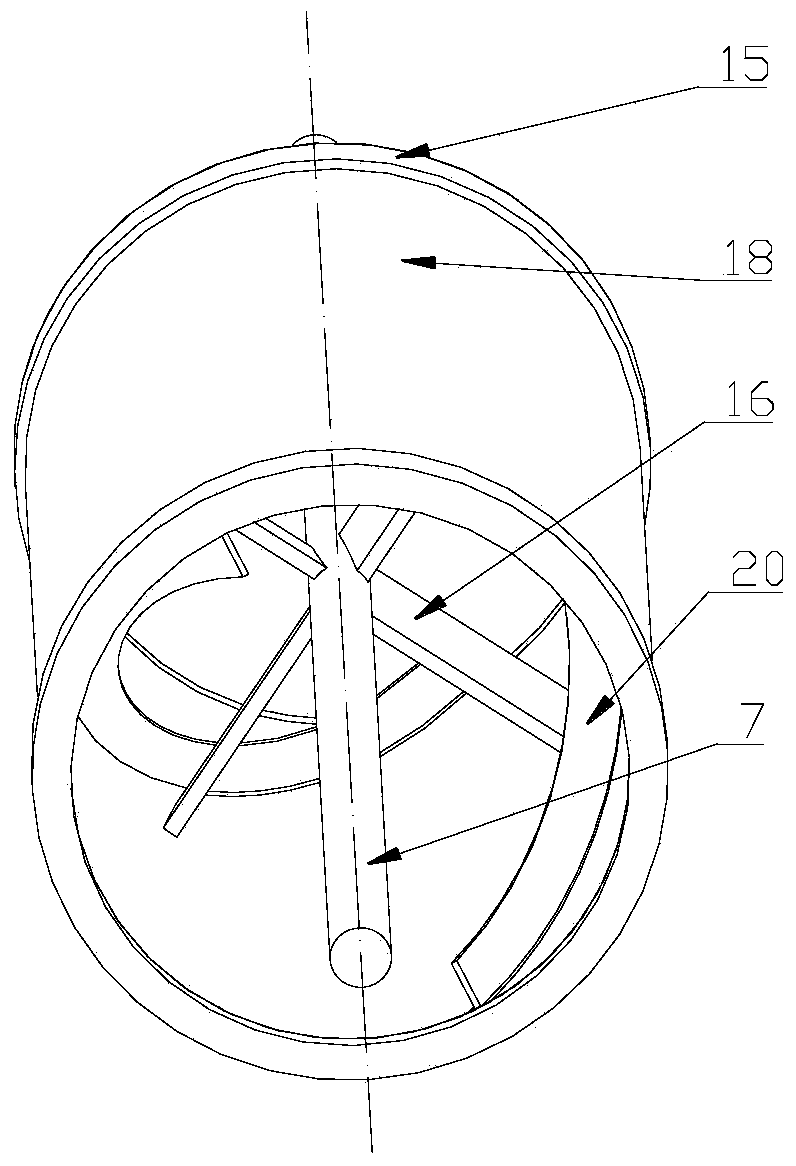

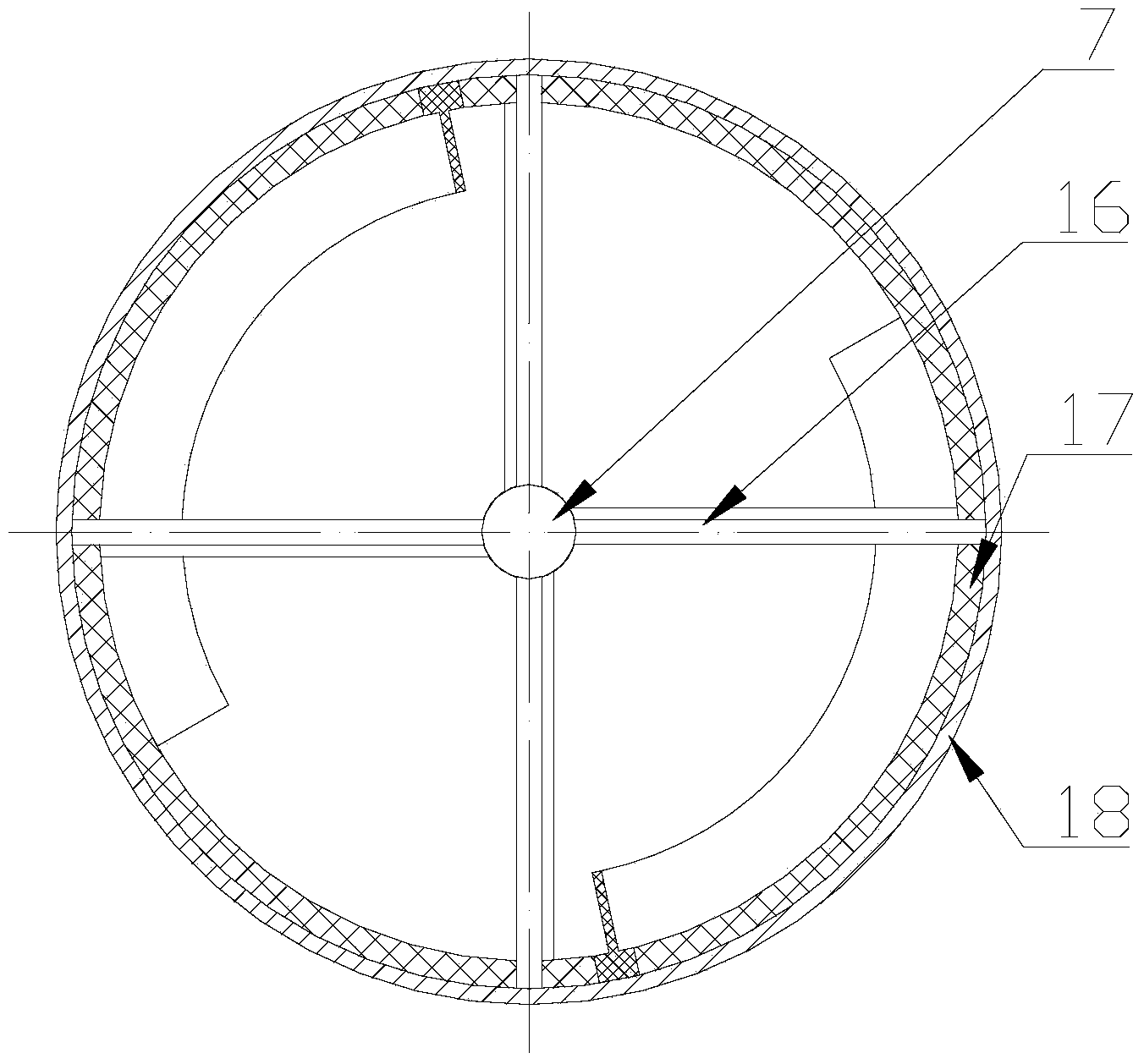

[0099] Such as figure 1 with Figure 8 , as shown in the axial schematic diagram of this embodiment and the schematic diagram of component assembly data, it shows the various components of the two-way separation device of the walnut shell kernel drum under the coupling action of pneumatic force and flexible helical blades. The diameter of the main shaft 7 is d 1 (d 1 =30~40mm), the two ends are respectively positioned on the frame 2 through the self-aligning ball bearing I3 and the self-aligning ball bearing II10, the main shaft 7 is connected with the output shaft of the reduction motor 9 through the star-shaped elastic coupling 8; the reduction motor 9 The rotation speed is w (w=0.55~1.20r / s), and it is fixed on the motor base 11 by bolts. The corresponding screw hole of the motor base 11 is a long-diameter through hole, which can realize the fine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com