Pour point depression and viscosity reduction agent and preparation method thereof

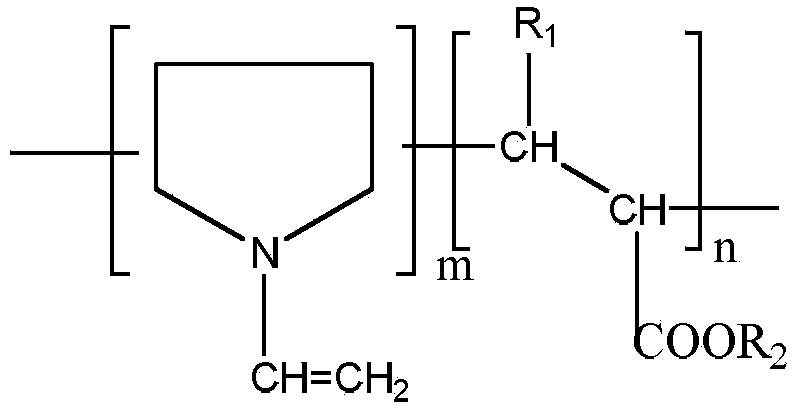

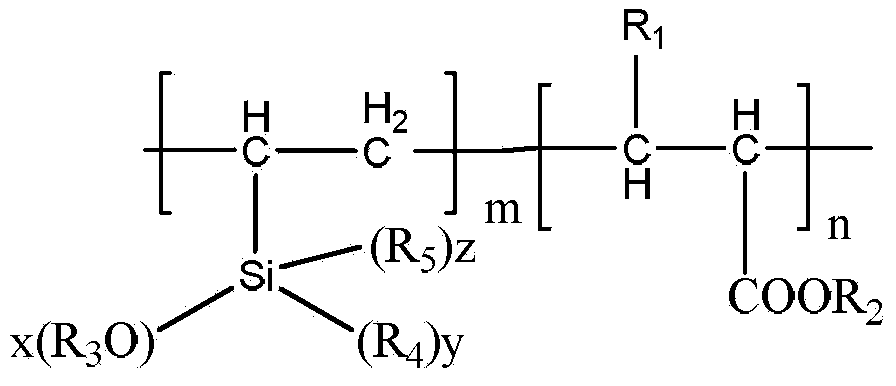

A technology of viscosity reducer and auxiliary agent, which is applied in the field of oil-soluble temperature-resistant, salt-resistant, pour point and viscosity reducer and its preparation, can solve the problems of poor temperature-resistant and salt-resistant performance, unsatisfactory application effect, and poor universality. Good pour point depressing, enhanced miscibility and universal applicability, low degree of order effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

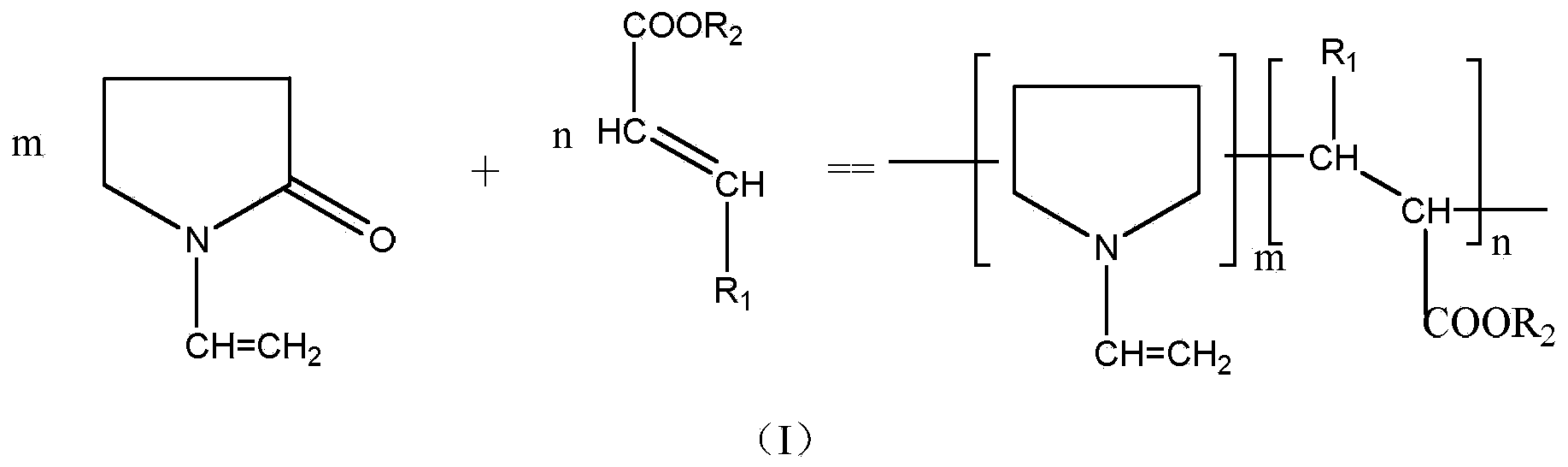

Method used

Image

Examples

Embodiment 1

[0066]1) Add 108.0g of stearyl alcohol, 273.6g of toluene, 1.36g of p-toluenesulfonic acid and 0.68g of hydroquinone in a 250ml three-necked flask equipped with a thermometer, reflux condenser, stirrer and water separator, and heat to Dissolve it completely at 60°C, then add 28.8g of acrylic acid, continue to heat up to 110°C, react at constant temperature for 8h, and stop the reaction. After the reaction, the mixed solution obtained is poured into a separatory funnel, neutralized and washed with 5% by mass of NaOH solution, to remove the catalyst and polymerization inhibitor until the water layer is colorless, then repeatedly washed with a large amount of deionized water until Neutral, dried in a vacuum oven at 40°C for 6 hours, the waxy solid finally obtained was octadecyl acrylate.

[0067] 2) Add 97.2g of octadecyl acrylate to a three-necked flask equipped with a condenser, a thermometer and a stirrer, raise the temperature to 60°C, and after it melts, add 11.1g of vinylpy...

Embodiment 2

[0072] 1) In a 250ml three-neck flask equipped with a thermometer, reflux condenser, stirrer and water separator, add 85.6g of tetradecyl alcohol, 273.6g of toluene, 1.36g of p-toluenesulfonic acid and 0.68g of hydroquinone in sequence, and heat to Dissolve it completely at 60°C, then add 34.4g of methacrylic acid, continue to heat up to 110°C, react at constant temperature for 8h, and stop the reaction. After the reaction, the mixed solution obtained is poured into a separatory funnel, neutralized and washed with 5% by mass of NaOH solution, to remove the catalyst and polymerization inhibitor until the water layer is colorless, then repeatedly washed with a large amount of deionized water until Neutral, use a vacuum oven to dry at 40°C for 6 hours, and the finally obtained waxy solid is tetradecyl methacrylate.

[0073] 2) Add 84.6g of tetradecyl methacrylate into a three-necked flask equipped with a condenser, a thermometer and a stirrer, raise the temperature to 60°C, and a...

Embodiment 3

[0078] 1) Add 72.6g of cetyl alcohol, 273.6g of toluene, 1.36g of p-toluenesulfonic acid and 0.68g of hydroquinone in a 250ml three-neck flask equipped with a thermometer, reflux condenser, stirrer and water separator, and heat to Dissolve it completely at 60°C, then add 25.8g of methacrylic acid, continue to heat up to 110°C, react at constant temperature for 8h, and stop the reaction. Pour the mixed solution obtained after the reaction into a separatory funnel, neutralize and wash with a 5% NaOH solution to remove the catalyst and polymerization inhibitor until the water layer is colorless, then repeatedly wash with a large amount of deionized water until Neutral, dried in a vacuum oven at 40°C for 6 hours, the waxy solid finally obtained was hexadecyl methacrylate.

[0079] 2) Add 88.8g cetyl methacrylate to a three-necked flask equipped with a condenser, a thermometer and a stirrer, raise the temperature to 60°C, and after it melts, add 12.8g of vinyl diethylmethylsilane a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com