Control method for nitrogen content of molten steel of wear-resistant steel

A control method and wear-resistant steel technology, applied in the field of metallurgy, can solve problems such as poor surface quality of continuous casting slabs, failure of steel benefits to be brought into play, and decline in steel plasticity, so as to achieve the effect of improving the internal and surface quality of casting slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

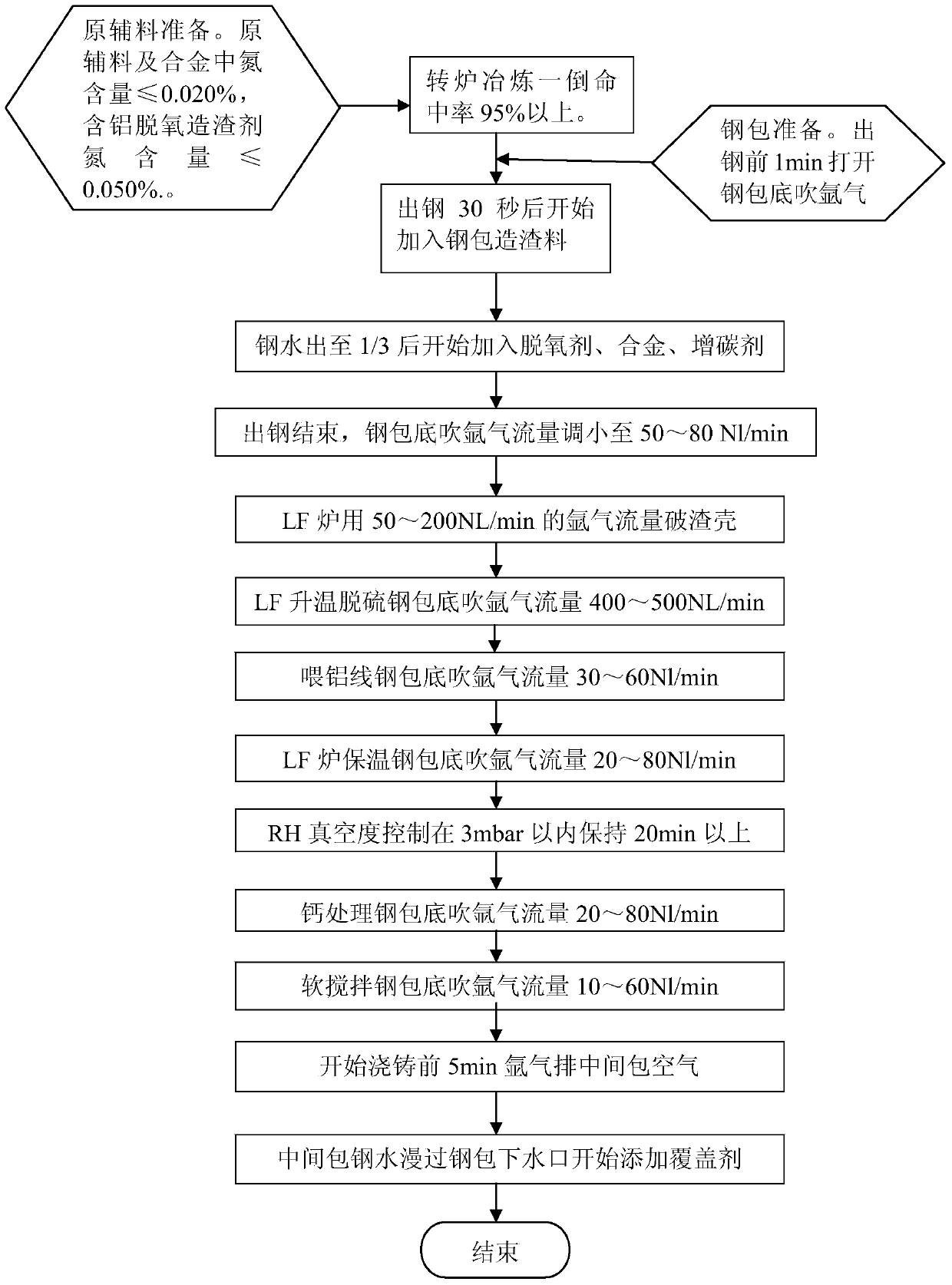

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, NM500 steel is selected, smelted in a 150-ton converter, a 150-ton ladle furnace, and cast in a slab continuous casting machine. In order to improve the surface and internal quality of the slab, the nitrogen content at the end of NM500 smelting is required to be controlled within 0.0050%.

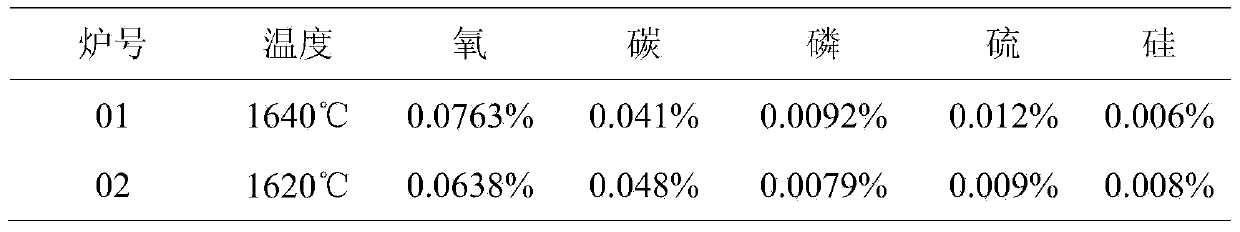

[0037] (1) Converter blowing. The composition and temperature control at the end of blowing meet the requirements, and the converter does not carry out supplementary blowing. See Table 1.

[0038] Table 1 Composition at the end point of converter (%)

[0039]

[0040] (2) Deoxidation and slagging alloying after converter furnace. 1 minute before tapping, open the ladle bottom blowing argon flow and set the flow rate to 500NL / min, and add the auxiliary materials in the order of tapping: start tapping→refining slag, lime→aluminum block→silicomanganese, low-carbon ferromanganese.

[0041] (3) Tapping ends. After tapping and alloying, the ladle bottom blowing fl...

Embodiment 2

[0047] In this embodiment, NH1250 steel is selected, smelted in a 150-ton converter, a 150-ton ladle furnace, and cast in a slab continuous casting machine. In order to improve the surface and internal quality of the slab, the nitrogen content at the end of NH1250 smelting is required to be controlled within 0.0060%.

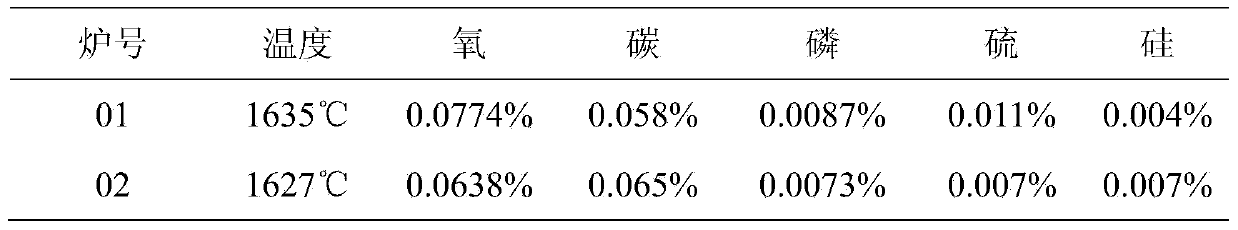

[0048] (1) Converter blowing. The composition and temperature control at the end of blowing meet the requirements, and the converter does not carry out supplementary blowing. See Table 2.

[0049] Table 2 Converter end point composition (%)

[0050]

[0051] (2) Deoxidation and slagging alloying after converter furnace. 1 minute before tapping, open the ladle bottom blowing argon flow and set the flow rate to 350NL / min, and add auxiliary materials in the tapping process sequence: start tapping → refining slag, lime → aluminum block → silicon manganese, low carbon ferromanganese.

[0052] (3) Tapping ends. After tapping and alloying, the ladle bottom blow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com