Building curtain wall glass fiber reinforcement composite board mounting assembly and method

A glass fiber and installation method technology, which is applied to building components, buildings, building structures, etc., can solve the problems of difficult adjustment of the upper and lower spacing of the decorative panel, difficult construction, and high waste generation rate, and can overcome the easy cracking of expansion joints and joints. The effect of avoiding secondary measurement and simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

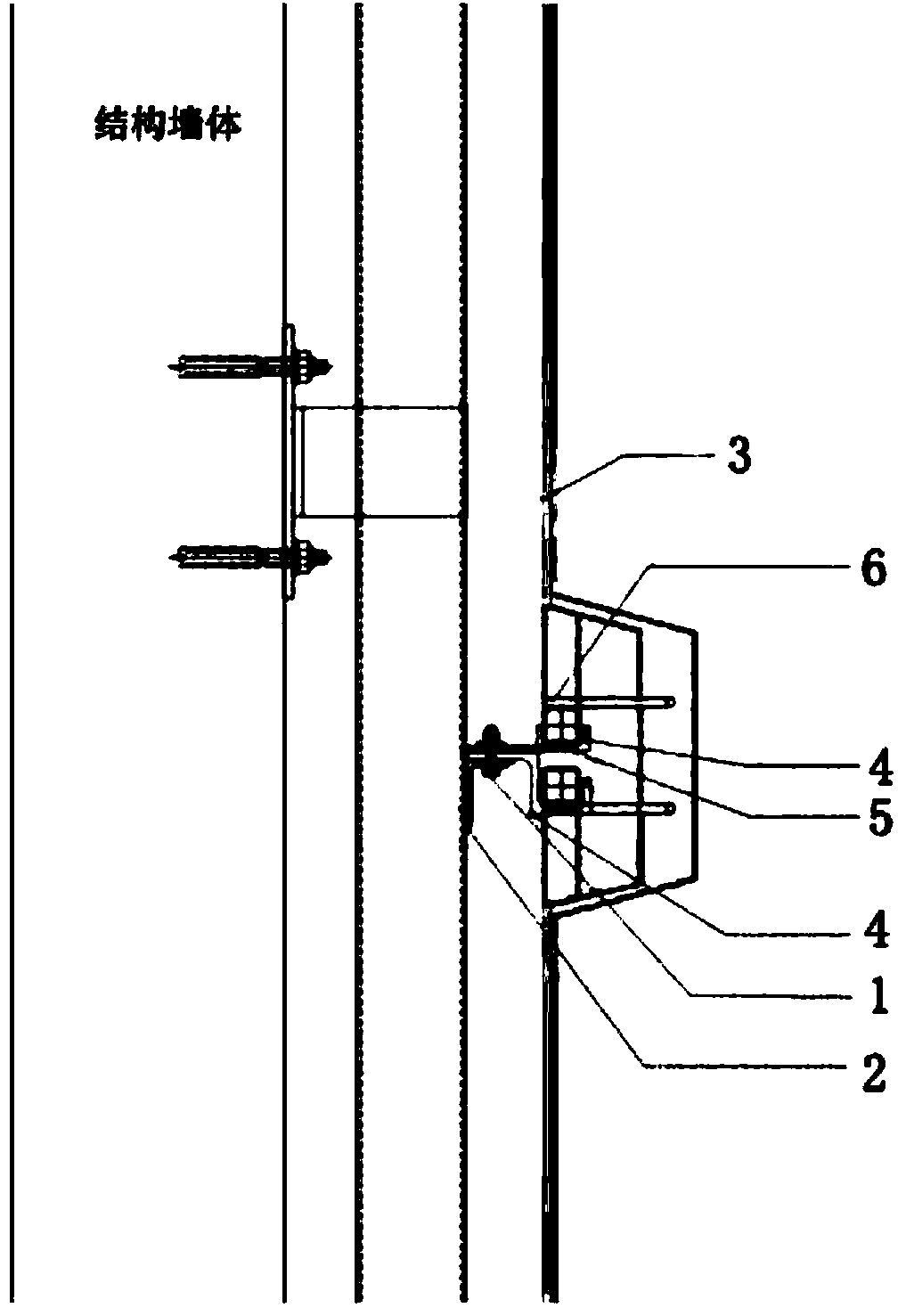

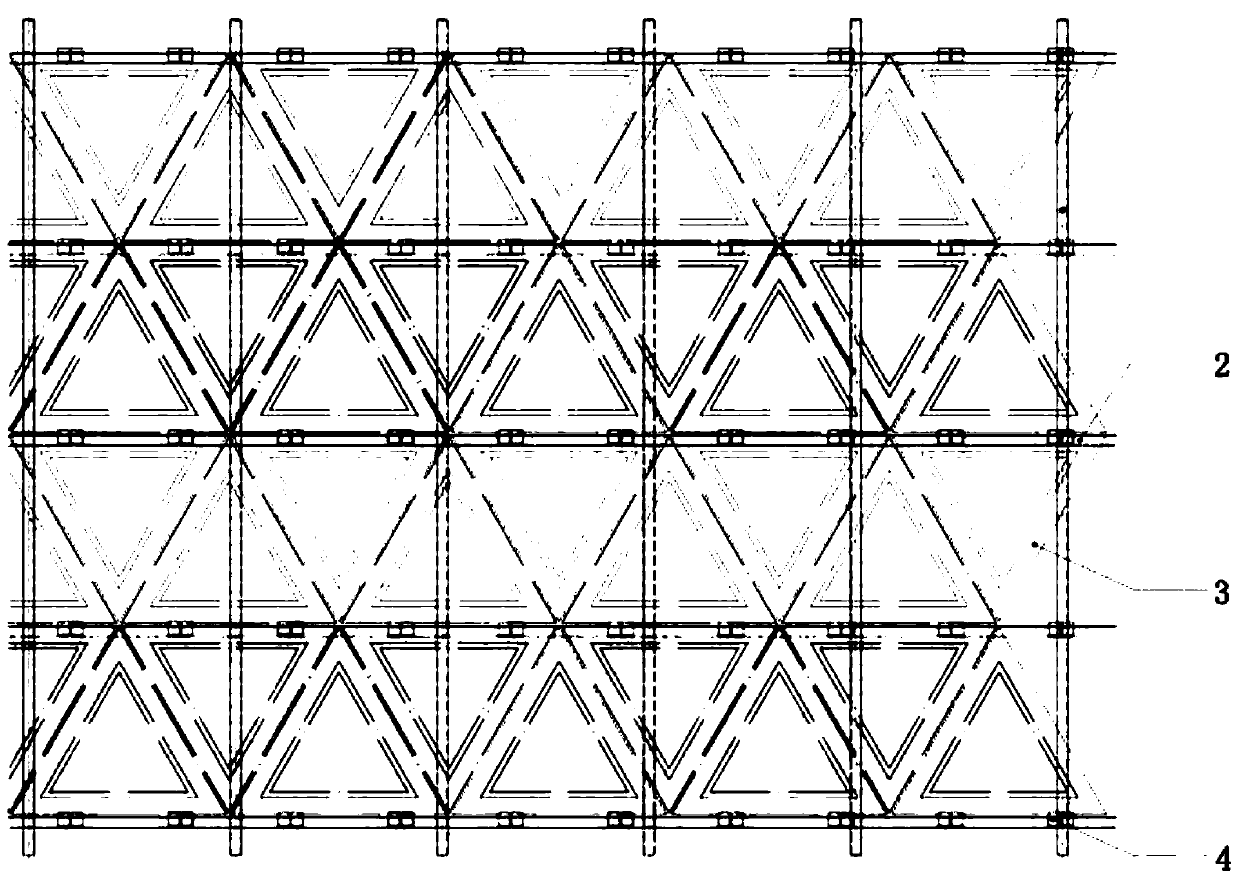

[0028] like figure 1 and figure 2 As shown, a building curtain wall glass fiber reinforced composite panel installation assembly includes bolt group 1, angle steel 2 and glass fiber reinforced composite panel 3, and also includes adapter 4, steel pad 5 and fixing pipe 6.

[0029] The fixed pipe 6 is installed inside the glass fiber reinforced composite board 3; the adapter 4 is fixed up and down on the angle steel 2 in the reserved hole through the bolt group 1, the fixed pipe 6 is stuck in the adapter 4, and the steel pad 5 is located in the adapter 4 and the lower part of the fixed pipe 6, and the adapter 4 and the fixed pipe 6 are welded and fixed.

[0030] The adapter 4 is pre-processed according to the measured dimensions.

[0031] The steel pad 5 is a galvanized steel pad.

[0032] The glass fiber reinforced composite board 3 adjusts the number and spacing of the installed components according to the weight division, the thickness and quantity of the steel pad 5 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com