A kind of positive electrode of battery, its preparation method and lithium ion secondary battery

A cathode and battery technology, applied in the battery field, can solve problems such as unsatisfactory rate performance, poor cycle performance, and easy material loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

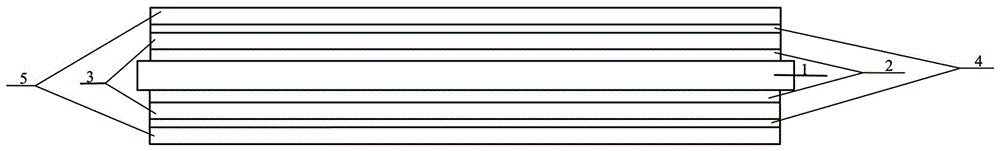

[0028] The present invention also provides a method for preparing the positive electrode, which is characterized in that the method includes firstly attaching the first conductive material to the conductive substrate, then attaching the first active material layer on the first conductive material layer, and then carrying out the first pressing step. sheet, and then attach the second conductive material layer on the first active material layer, and then attach the second active material layer on the second conductive material layer, and then carry out the second sheeting, wherein, the second sheeting after the second sheeting The compacted density of the active material layer is lower than the compacted density of the first active material layer after the first tableting.

[0029] Preferably, the compacted density of the second active material layer is 0.01-0.5 g / cm lower than the compacted density of the first active material layer 3 , further preferably, the compacted density...

Embodiment 1

[0049] (1) Preparation of positive electrode

[0050] The purchased aluminum foil current collector with a width of 400 mm and a thickness of 15 microns is degreased and cleaned, and then etched by a high-pressure plasma corona machine to obtain an aluminum foil with increased surface tension.

[0051] Mix 750g of NMP, 10g of PVP powder and 20g of PVDF (polyvinylidene fluoride), then add 220g of conductive carbon black and stir evenly to obtain the first conductive paste, and evenly coat the first conductive paste on Both surfaces of the treated aluminum foil 1 are coated with a thickness of 2-3 μm on each side, and then vacuum-dried at 90° C. for 0.5 hour to obtain a first conductive material layer 2 with a thickness of about 4 μm attached to the conductive substrate.

[0052] Mix 2000g of NMP and 60g of PVDF, then add 50g of conductive carbon black and stir evenly, and finally add 2000g of lithium iron phosphate and stir evenly to obtain the first positive electrode slurry (...

Embodiment 2

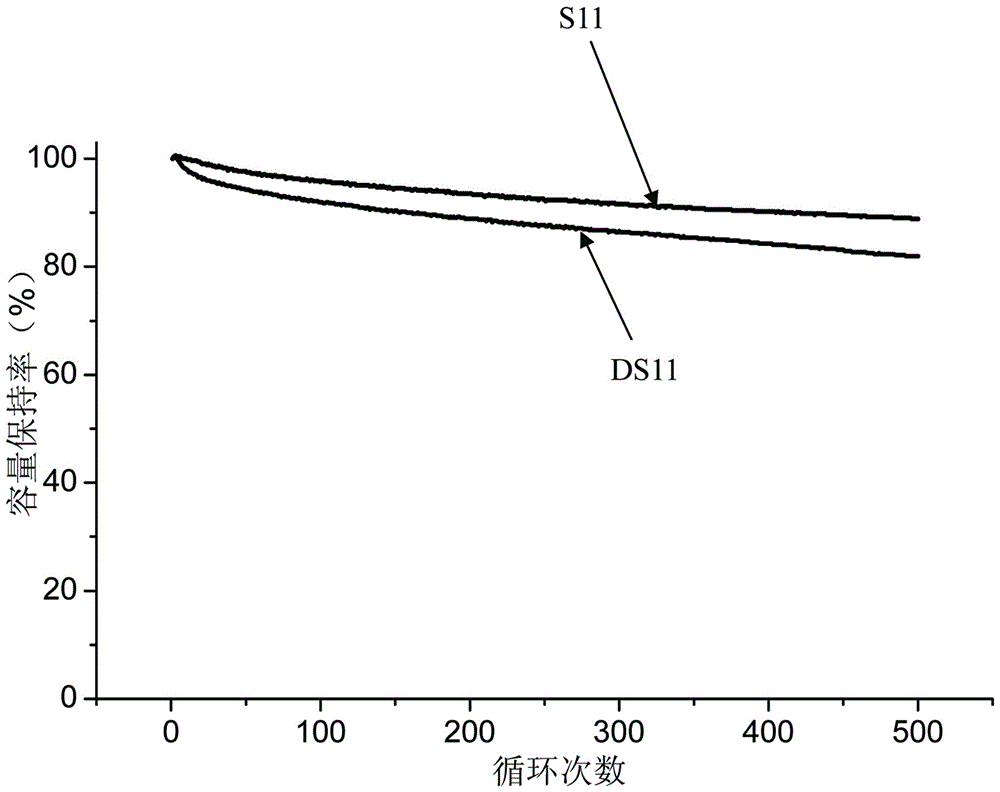

[0061] Positive electrode S2 and battery S22 were prepared by the same method as in Example 1, except that the pressure of the first tablet of the first active material layer was 50 MPa, and the compacted density was 2.2 g / cm 3 the first active material layer. The pressure of the second tablet pressing of the second active material layer is 45 MPa, and the compaction seal is 2.15g / cm 3 the second active material layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com