Heat conduction asphalt concrete road surface temperature difference power generation system

An asphalt concrete and thermoelectric power generation technology, which is applied in the directions of generators/motors, roads, roads, etc., can solve the problems of poor thermal conductivity, limit the promotion of urban asphalt pavement thermoelectric power generation systems, and affect the power generation efficiency of the system. The effect of reducing road rutting damage and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

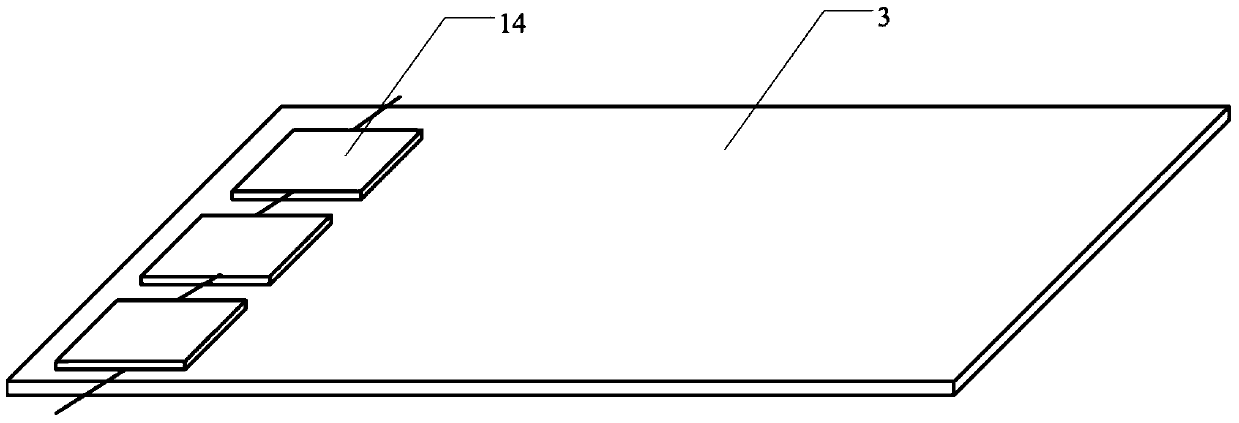

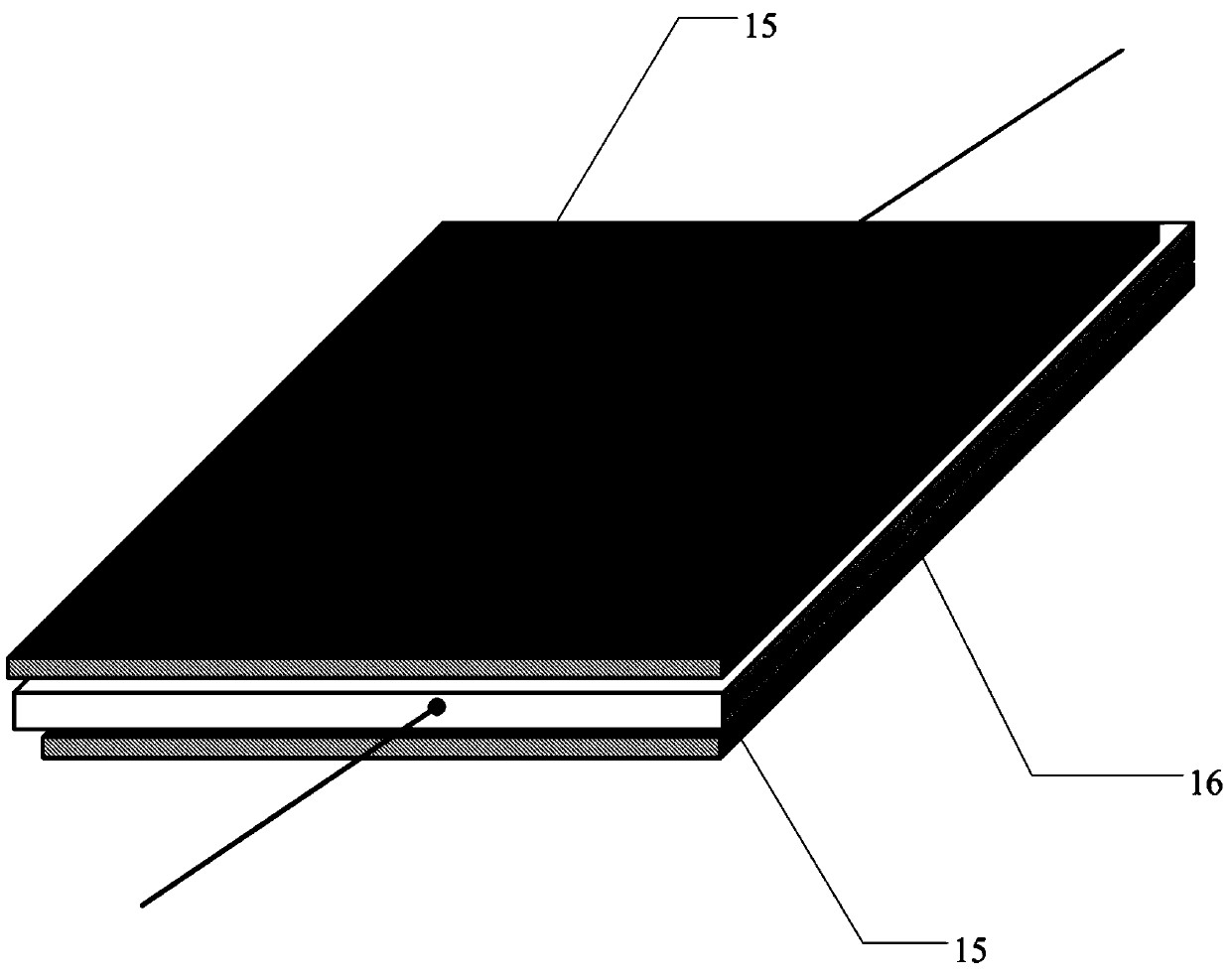

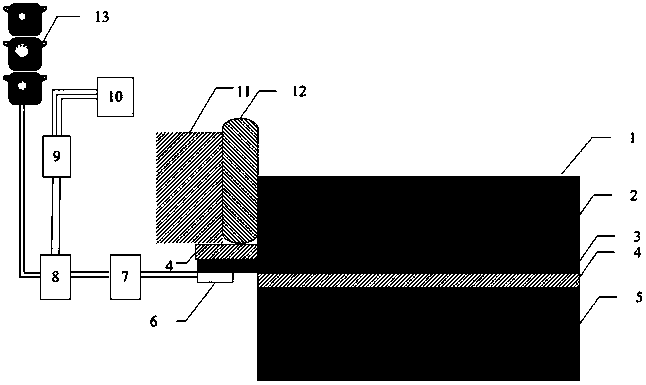

[0017] The invention is a heat-conducting asphalt concrete pavement temperature difference power generation system, its structure is as follows figure 1 As shown, it includes: a solar heat collection system laid on the roadbed 5, and its structure is an emulsified asphalt concrete seal layer 1, a heat-conducting asphalt concrete layer 2, a heat-conducting aluminum sheet 3, and a heat-insulating material layer 4 from top to bottom; The semiconductor thermoelectric power generation module group 6 is set at the lower end of the heat conduction aluminum sheet 3 and at a certain depth of the soil in the green belt 11, and is composed of a plurality of semiconductor thermoelectric power generation module modules 14 connected in series, wherein the structure of the semiconductor thermoelectric power generation module 14 is thermally conductive silicon from top to bottom. Grease 15, semiconductor thermoelectric power generation sheet 16, heat conduction silicone grease 15, the lower en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com