Tissue culture seedling rapid transplanting machine based on laser cutting and transplanting method thereof

A technology for laser cutting and tissue culture seedlings, applied in planting methods, transplanting machinery, applications, etc., can solve the problems of low work efficiency and high cost, and achieve the effects of high work efficiency, strong applicability, and improved cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

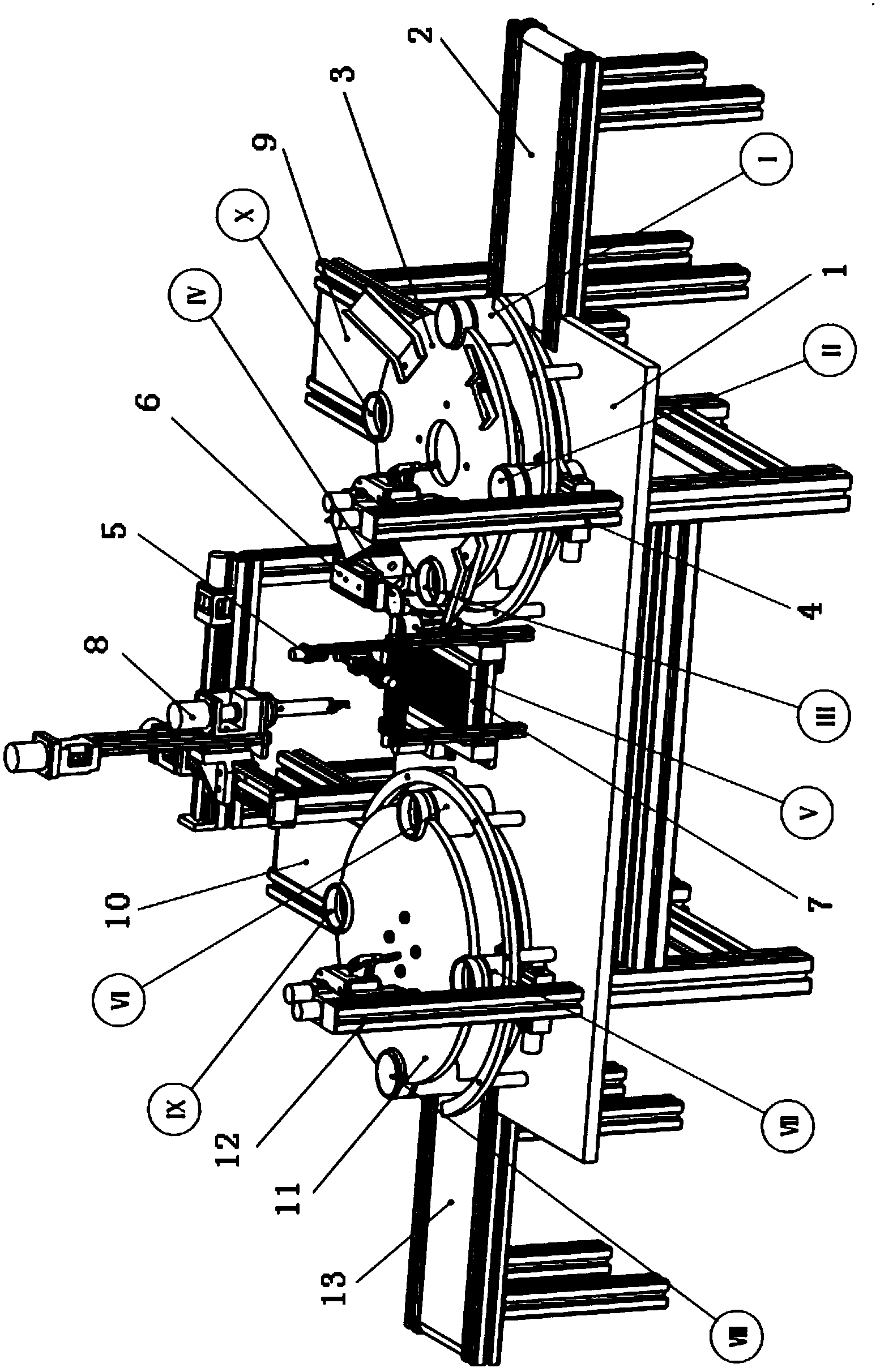

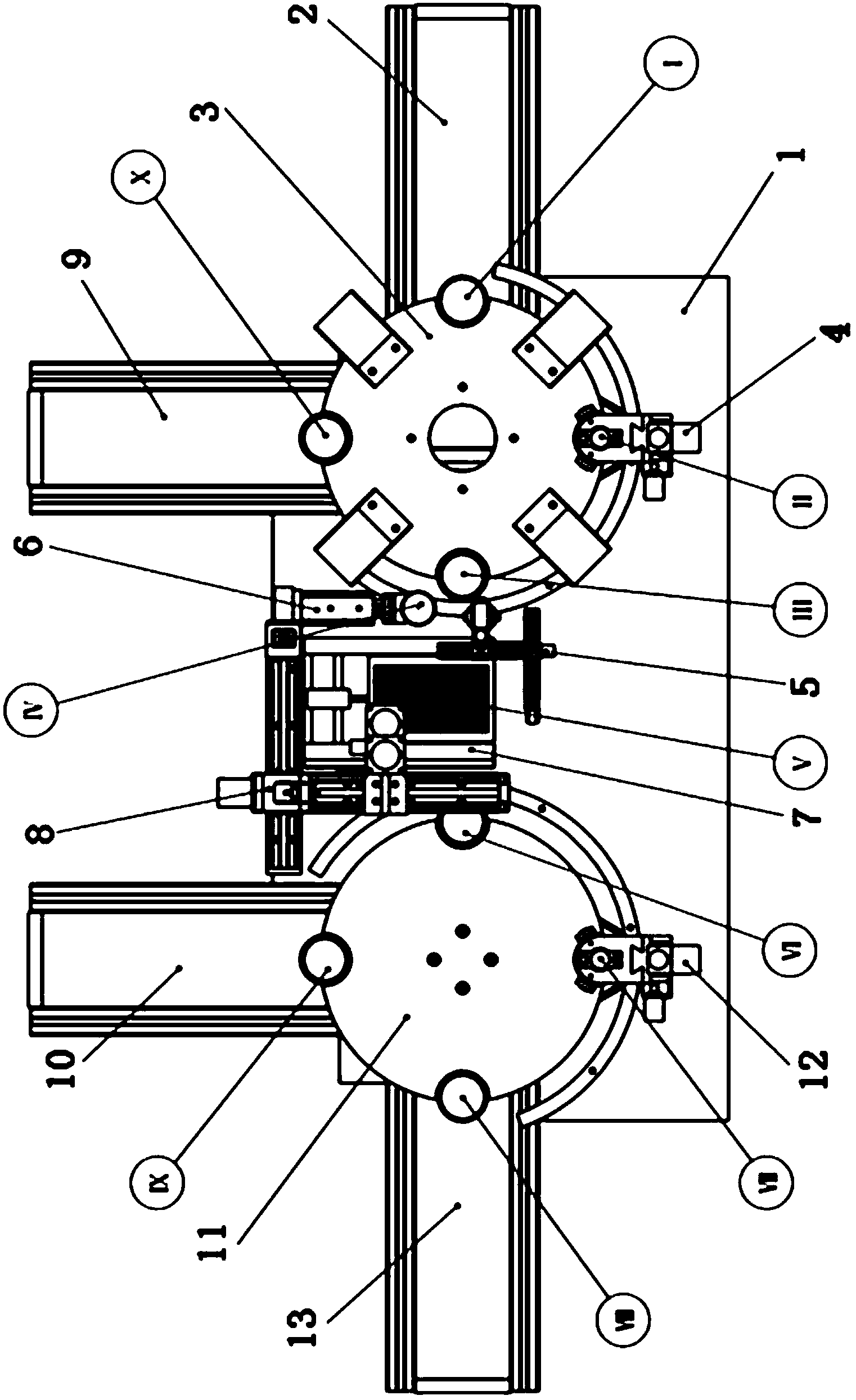

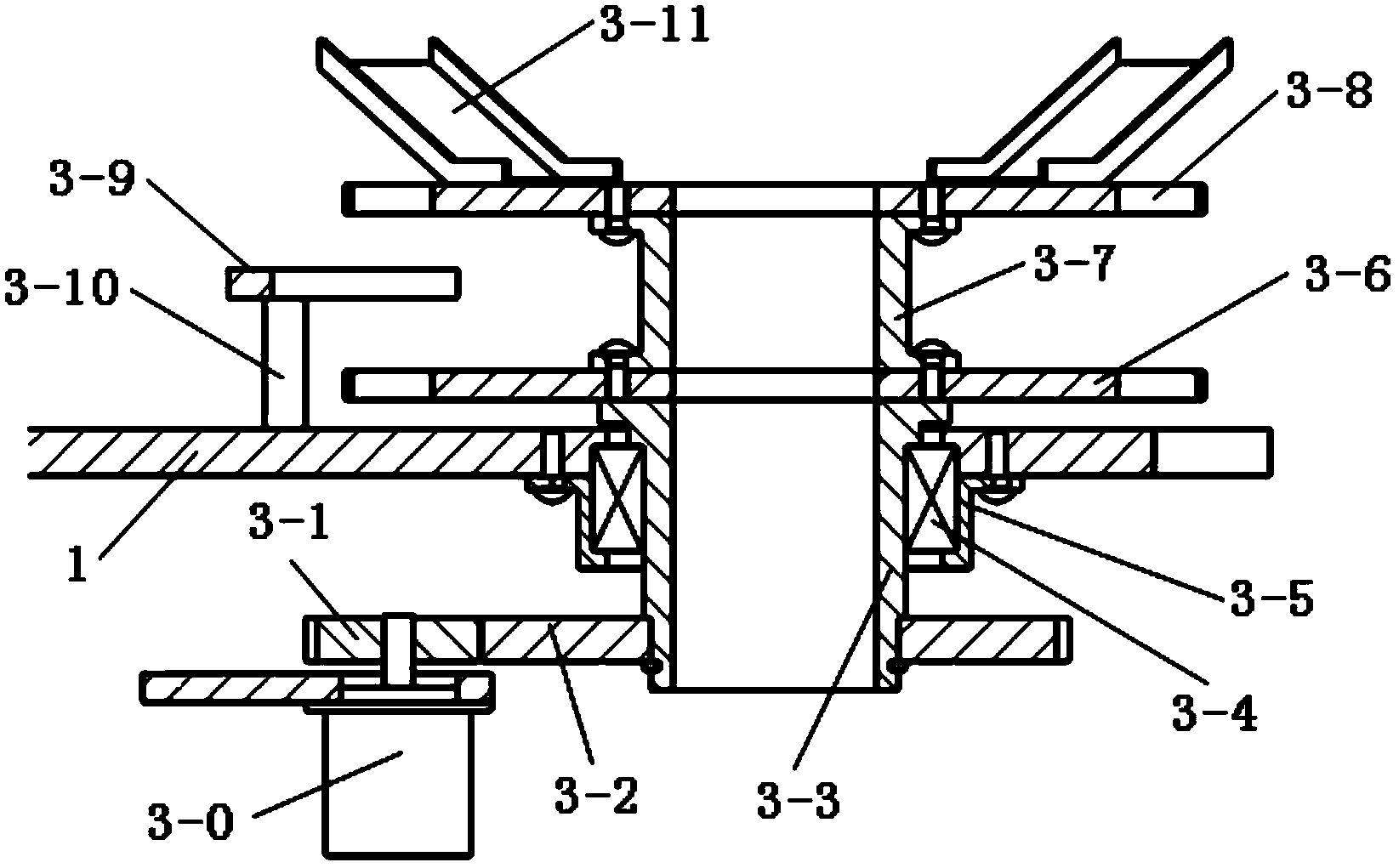

[0019] like figure 1 , figure 2 Shown, the present invention comprises a workbench 1, a mother bottle and moves into conveyor belt 2, a mother bottle conveying mechanism 3, a cover opening mechanism 4, a seedling picking mechanism 5, a root-cutting mechanism 6, a screening mechanism 7, a transplant Mechanism 8, a mother bottle move out of the conveyor belt 9, a child bottle moves into the conveyor belt 10, a child bottle conveying mechanism 11, a capping mechanism 12 and a child bottle move out of the conveyor belt 13. The child bottle moving out conveyor belt 13 and the mother bottle moving in conveyor belt 2 are symmetrically arranged on the left and right sides of the workbench 1, and the child bottle moving in conveyor belt 10 and the mother bottle moving out conveyor belt 9 are arranged adjacent to the child bottle moving out conveyor belt 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com