Brown Chinese rice wine lactobacillus beverage and preparation method for same

A technology of lactic acid bacteria drink and fermented glutinous rice, which is applied in the direction of dairy products, milk preparations, applications, etc., can solve the problem of brown drinks lacking the flavor of fermented fermented glutinous rice, and achieve the effect of increasing uniqueness and nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Formula (see Table 1, 2)

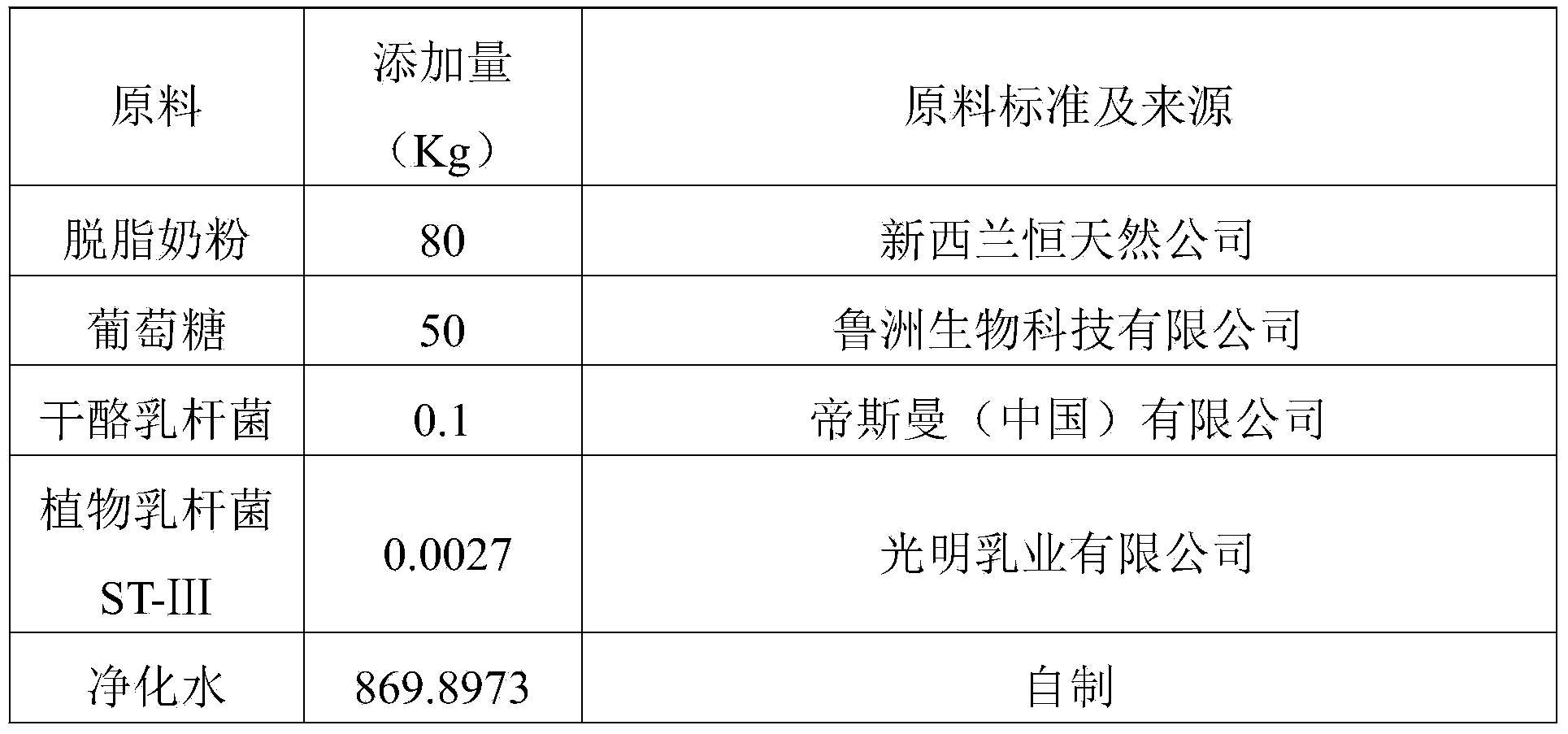

[0045] Table 1. Raw materials, addition amount and source of brown yoghurt (calculated on the basis of 1 ton of product)

[0046]

[0047] Table 2. Raw materials, addition amount and source of brown liqueur fermented lactic acid bacteria beverage (calculated on the basis of 1 ton of product)

[0048] raw material

Amount added (Kg)

Raw material standards and sources

brown yogurt

500

self made

0.15

Tianjin Binhai Jebsen Specialized Chemicals Co., Ltd.

sweet wine juice

50

Beijing Ershang CJ Food Co., Ltd.

[0049] pectin

3

CP Kelco

446.85

self made

[0050] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0051] 2. Preparation process of brown yoghurt

[0052] (1) Maillard reaction:

[0053] Mass ratio (based on 1000 parts by mass): skimmed mil...

Embodiment 2

[0063] 1. Formula (see Table 3, 4)

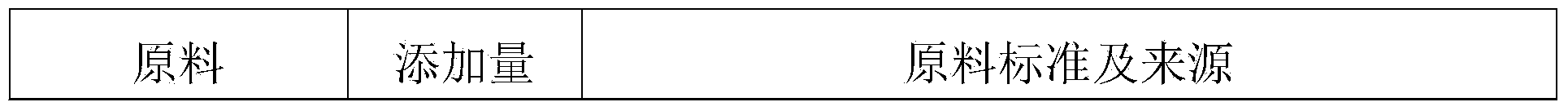

[0064] Table 3. Raw materials, addition amount and source of brown yoghurt (calculated on the basis of 1 ton of product)

[0065]

[0066]

[0067] Table 4. Raw materials, addition amount and source of brown liqueur fermented lactic acid bacteria beverage (calculated on the basis of 1 ton of product)

[0068]

[0069] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0070] 2. Preparation process of brown yoghurt

[0071] (1) Maillard reaction:

[0072] Mass ratio (based on 1000 parts by mass): skimmed milk powder: fructose syrup: purified water=120 parts: 100 parts: 780 parts.

[0073] Heat the purified water to 50°C, then add skim milk powder and proportioned fructose syrup, and hydrate under low-speed stirring. After dissolving for 45 minutes, raise the temperature of the hydrated base material to 121°C for Maillard reaction for 10 minutes until brown Change, the bro...

Embodiment 3

[0082] 1. Formula (see Table 5, 6)

[0083] Table 5. Raw materials, addition amount and source of brown yoghurt (calculated on the basis of 1 ton of product)

[0084]

[0085] Table 6. Raw materials, addition amount and source of brown liqueur fermented lactic acid bacteria beverage (calculated on the basis of 1 ton of product)

[0086] raw material

Amount added (Kg)

Raw material standards and sources

brown yogurt

450

self made

[0087] White sugar

70

Beijing Sugar Co., Ltd.

sweet wine juice

150

Beijing Ershang CJ Food Co., Ltd.

soybean polysaccharide

5

Beijing Zhongbai Venture Chemical Products Co., Ltd.

purified water

325

self made

[0088] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0089] 2. Preparation process of brown yoghurt

[0090] (1) Maillard reaction:

[0091] Mass ratio (based on 1000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com