Preparation method of non-fried instant Chinese yam crisp chips

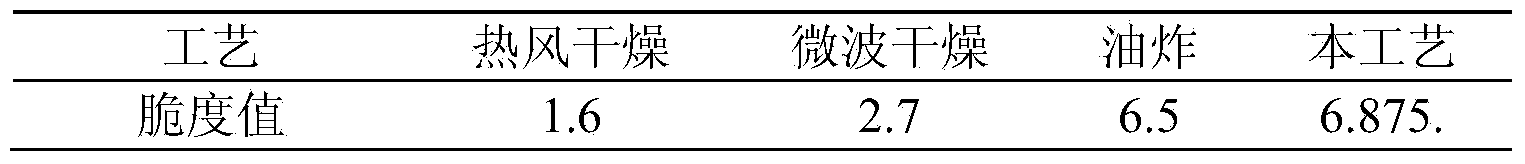

A non-fried, yam chip technology, which is applied in the field of preparation of non-fried instant yam crisps, can solve the problems of nutrient loss, vitamin destruction, and great harm to human body, and achieve long shelf life, low moisture content, and low processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Processing of raw materials: select fresh, complete, and non-mechanically damaged yams as raw materials, wash the soil on the surface with running water, and then peel off the skin;

[0040] (2) Cut the peeled yam into slices with a thickness of 1.5mm;

[0041] (3) Put the yam flakes obtained in step (2) into 0.2% citric acid, 0.2% Vc, 0.02% NaHSO 3 ; Soak in the color protection solution for 30min.

[0042] (4) Blanch the yam slices after the color protection in step (3) in hot water at 95-100°C, and cool in cold water;

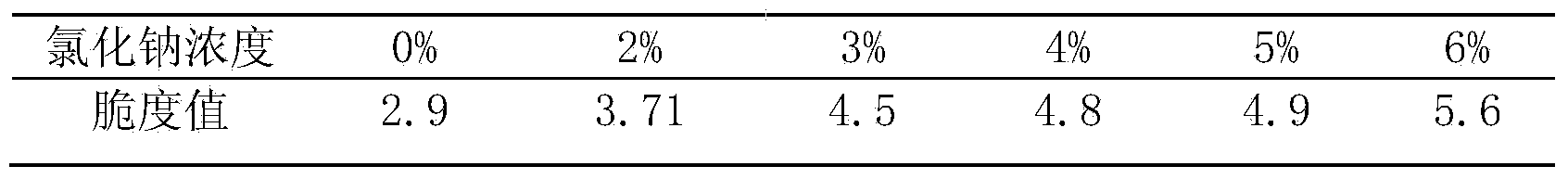

[0043] (5) Soak the yam slices blanched in step (4) in 3% NaCl, 0.5% sucrose solution for 5 minutes, remove and drain the surface water;

[0044] (6) Heat pump drying: The yam slices soaked in step (5) are subjected to heat pump drying, the heat pump drying temperature is 55°C, and the hot air velocity is 1.0m / s;

[0045] (7) Put the yam slices dried by hot air in step (6) into the microwave oven for the second stage of microwave, so that the f...

Embodiment 2

[0047] Embodiment 2: with embodiment 1, the difference is,

[0048] (2) The slice thickness is 1.5mm;

[0049] (3) The composition of the color protection liquid is 0.1% citric acid, 0.2% Vc, 0.01% NaHSO 3 ;

[0050] (5) Soak yam tablets in 2% NaCl, 0.3% sucrose solution for 5 minutes;

[0051] (6) Heat pump drying, temperature 45°C, wind speed 0.4m / s;

[0052](7) The microwave power of the first section is 420W, and the time is 80s, and the microwave power of the second section is 490W, and the time is 90s; the measured brittleness value of the product is 5.5, the color L* value is 48.87, and the b* value is 14.9. The expansion degree is 20%.

Embodiment 3

[0053] Embodiment 3: with embodiment 1, the difference is,

[0054] (2) The slice thickness is 4mm;

[0055] (3) The composition of the color protection liquid is 0.1% citric acid, 0.4% Vc, 0.02% NaHSO 3 ;

[0056] (5) Soak yam tablets in 3% NaCl, 1% sucrose solution for 5 minutes;

[0057] (6) Heat pump drying, temperature 65, ℃ wind speed 2.0m / s;

[0058] (7) The microwave power of the first section is 630W, and the time is 80s, and the microwave power of the second section is 490W, and the time is 70s; the measured brittleness value of the product is 4.33, the color L* value is 38.29, and the b* value is 13.31. The expansion degree is 26%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com