A kind of preparation method of hierarchical mesoporous silica nanoparticles

A mesoporous silica and nanoparticle technology, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of harsh synthesis conditions, high cost, and easy aggregation of particles, and achieve a wide range of pore size distribution and reduce Synthetic cost, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

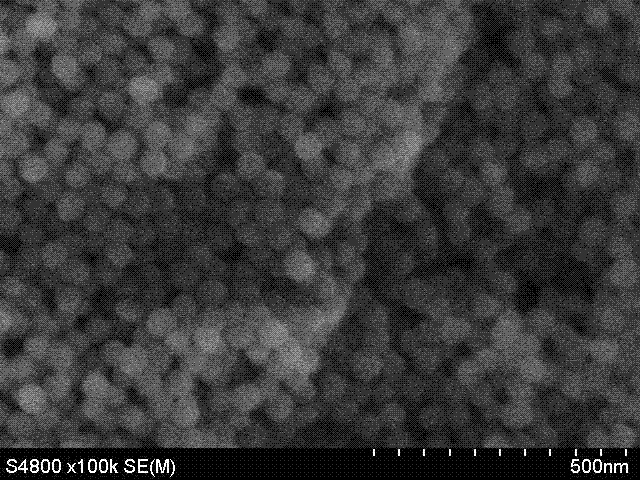

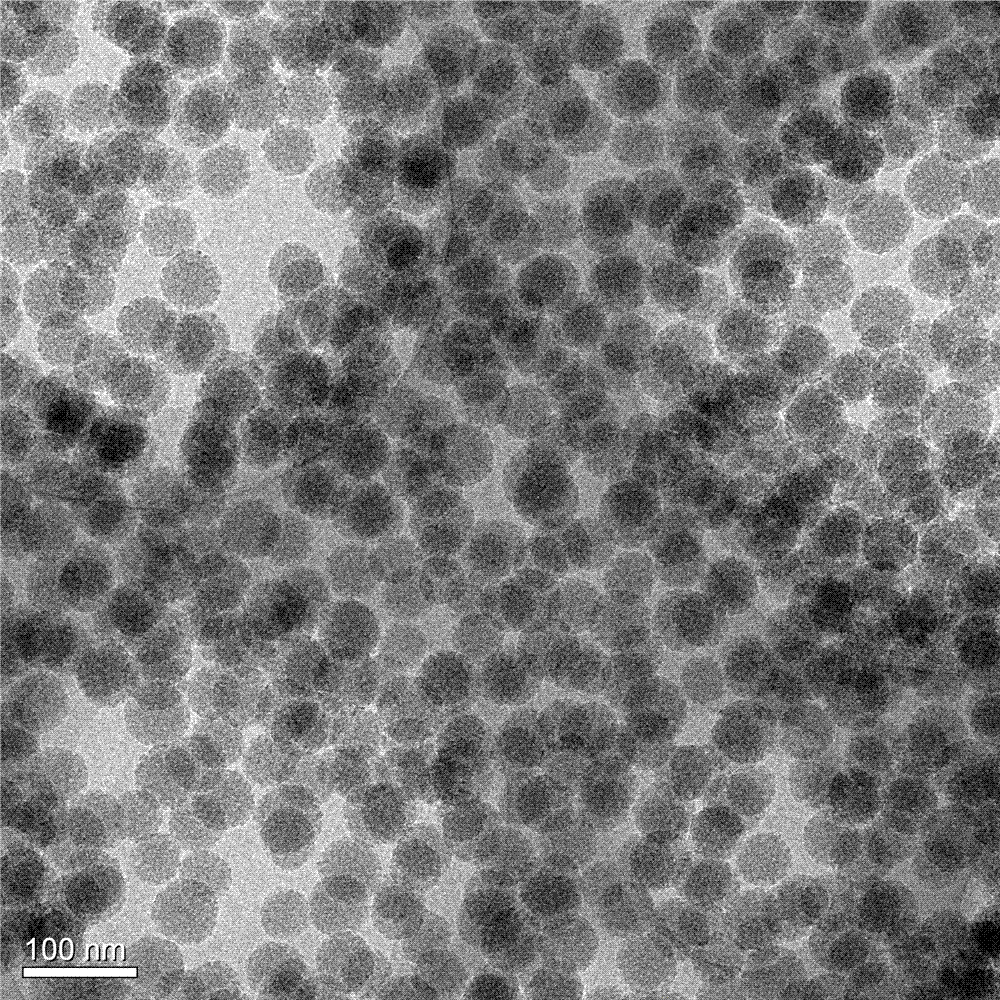

[0020] First, 1.63 g of 1-hexadecyl-3-methylimidazolium trifluoromethanesulfonate (C 16 -ILs) was added to a solution containing 100 ml deionized water and 3.7 g triethanolamine (TEAH 3 ) in a beaker at a constant temperature of 80°C for 1 hour until the solution becomes clear, then quickly add 14.6 g of tetraethoxysilicate (TEOS) into the beaker, and continue to stir at a constant temperature of 80°C for 2 hours to obtain a milky white colloidal state suspension, the molar composition of the mixture is SiO 2 : C 16 -ILs : TEAH 3 : H 2 O = 1 : 0.06 : 1.0 : 80; the obtained mixture was centrifuged, washed, and dried to obtain the hierarchical mesoporous SiO 2 Nanoparticles, yield 70%, average particle size 45 nm ( figure 1 and figure 2 ). The specific surface area of the particles is 834 m 2 / g, 1.87 ml / g, the pore size ranges from 2 to 20 nm.

Embodiment 2

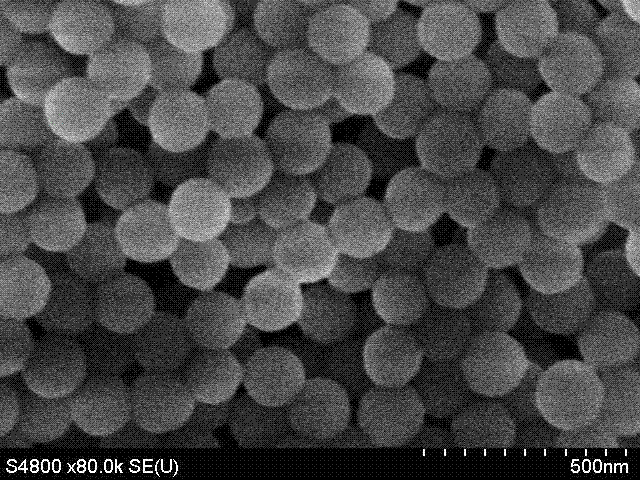

[0022] First, 1.63 g of 1-dodecyl-3-methylimidazolium trifluoromethanesulfonate (C 12 -ILs) was added to a solution containing 100 ml deionized water and 3.7 g triethanolamine (TEAH 3 ) in a beaker at a constant temperature of 80°C for 1 hour until the solution becomes clear, then quickly add 14.6 g of tetraethoxysilicate (TEOS) into the beaker, and continue to stir at a constant temperature of 80°C for 2 hours to obtain a milky white colloidal state suspension, the molar composition of the mixture is SiO 2 : C 12 -ILs : TEAH 3 : H 2 O = 1 : 0.06 : 1.0 : 80; the obtained mixture was centrifuged, washed, and dried to obtain the hierarchical mesoporous SiO 2 Nanoparticles, yield 75%, average particle size 200 nm ( image 3 and Figure 4 ). The specific surface area of the particles is 1034 m 2 / g, the pore volume is 1.27 ml / g, and the pore diameter ranges from 3.6 to 60 nm.

Embodiment 3

[0024] Except that tetramethoxysilicate (TMOS) was used instead of tetraethoxysilicate (TEOS) in Example 1, other preparation conditions were the same as in Example 1, and the hierarchical mesoporous SiO 2 The average particle size of nanoparticles is 30 nm. The specific surface area of the particles is 804 m 2 / g, the pore volume is 1.97 ml / g, and the pore diameter ranges from 2.6 to 20 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com