Water-based heat activated adhesive and preparation method thereof

A heat-activated, adhesive technology, applied in the direction of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of unfavorable rapid construction, unfavorable high-speed automatic production, high cost, etc., to protect life, health and safety, and effectively Conducive to automatic production and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

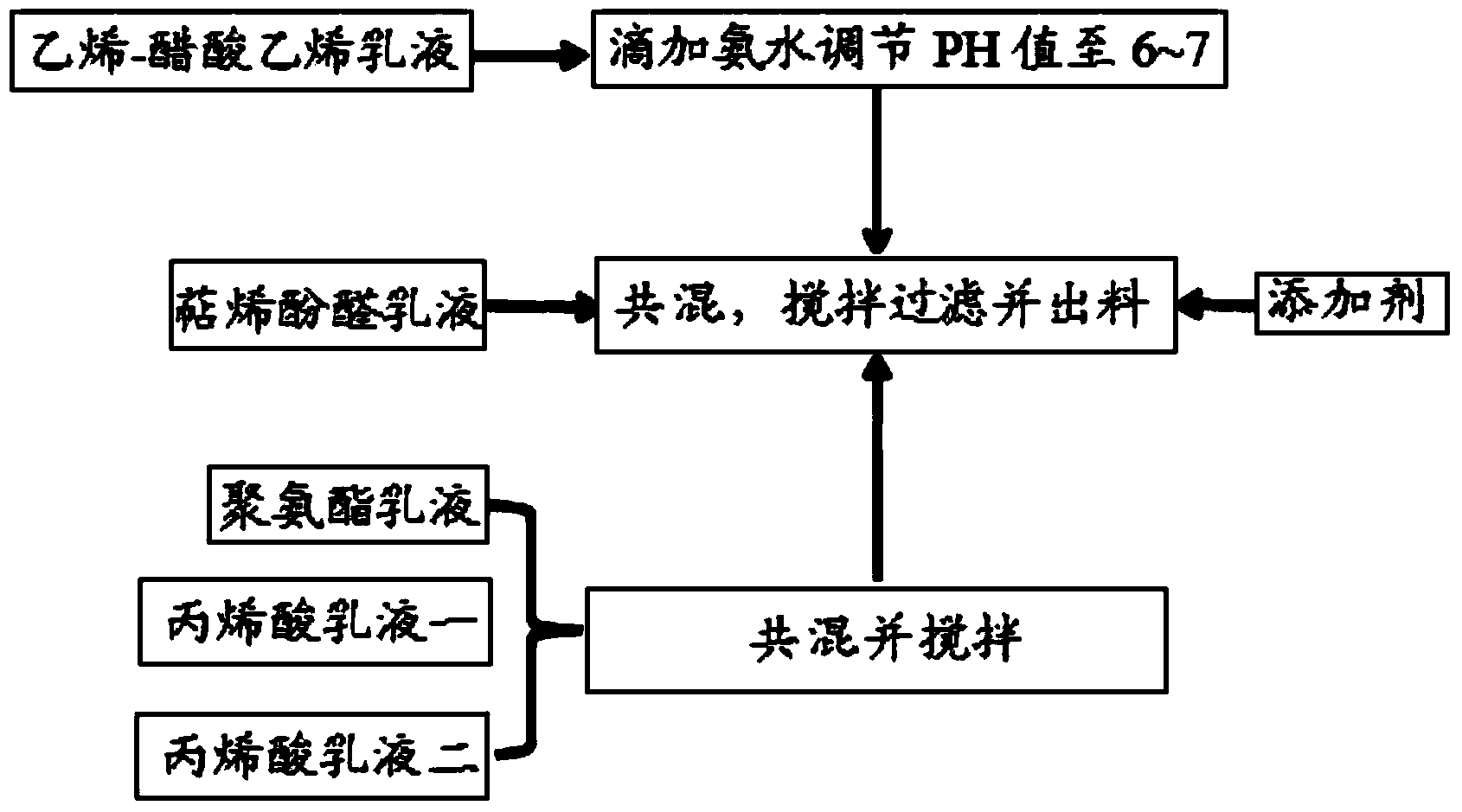

[0017] like figure 1 Shown, the present invention discloses a kind of preparation method of water-based heat-activated adhesive, it comprises the following steps,

[0018] S1. Put 5-20 parts by weight of ethylene-vinyl acetate emulsion into the first reaction kettle, and add ammonia water dropwise under stirring condition to adjust the pH value of the ethylene-vinyl acetate emulsion. Wherein the pH value ranges from 6 to 7, and the stirring time is 10 minutes. The above-mentioned ethylene-vinyl acetate emulsion is preferably 8 to 15 parts.

[0019] S2. Put 15-35 parts by weight of water-based polyurethane emulsion, 30-50 parts of acrylic emulsion, and 5-15 parts of another acrylic emulsion into the second reaction kettle and stir. Wherein, the stirring time in step S2 is 30min, and the rotating speed is 300RPM. The above-mentioned aqueous polyurethane emulsion is 22.5 parts; the acrylic emulsion is preferably 37.5 parts; another part of acrylic emulsion is preferably 10 par...

Embodiment 1

[0023] Add 5 g of ethylene-vinyl acetate emulsion into the first reaction kettle, add ammonia water dropwise under stirring condition, control the pH to 6, stir for 10 minutes, seal and store for later use. Add 15g water-based polyurethane emulsion, 50g acrylic emulsion one, and 10g acrylic emulsion two in the second reaction kettle, make the three stir and blend in the second reaction kettle, the rotating speed when stirring in the second reaction kettle is 300RPM, the stirring time for 30min. Then, add the emulsion system in the first reaction kettle to the second reaction kettle, then add 15g of terpene phenolic emulsion, 0.1g of wetting and leveling agent, and blend at a rotation speed of 300RPM and a stirring time of 300min , after fully stirring, the material is filtered and discharged to obtain the final product.

Embodiment 2

[0025] Add 10 g of ethylene-vinyl acetate emulsion into the first reaction kettle, add ammonia water dropwise under stirring, control the pH to 6, stir for 10 minutes, and seal it for future use. Add 35g water-based polyurethane emulsion, 30g acrylic emulsion one and 5g acrylic emulsion two in the second reaction kettle, make the three stir and blend in the second reaction kettle, the rotating speed when stirring in the second reaction kettle is 300RPM, the stirring time for 30min. Then, add the emulsion system in the first reaction kettle to the second reaction kettle, then add 15g of terpene phenolic emulsion, 0.1g of wetting and leveling agent, and blend at a rotation speed of 300RPM and a stirring time of 300min , after fully stirring, the material is filtered and discharged to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com