Test reagent for realizing online rapid nondestructive test of quality of gold plating layer and using method of test reagent

A non-destructive testing and coating technology, which is applied in the direction of chemical reaction of materials and material analysis by observing the influence of chemical indicators, which can solve the problem of inability to realize online non-destructive testing, cumbersome operation of testing technology, and long test time. and other problems, to achieve the effects of high test efficiency, strong wetting penetration, and simple use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

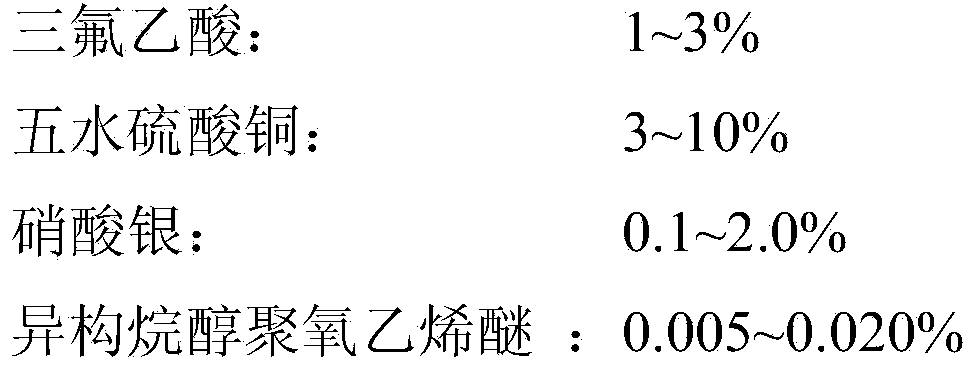

[0047] Test reagent components (percentage by weight): 3% trifluoroacetic acid, 10% copper sulfate pentahydrate, and the balance is pure water.

[0048] Conventional acid control components ① (percentage by weight): 3% hydrochloric acid, 10% copper sulfate pentahydrate, and the balance is pure water.

[0049] Conventional acid control component ② (percentage by weight): 3% hydrochloric acid, 3% trifluoroacetic acid, 10% copper sulfate pentahydrate, and the balance is pure water.

[0050] Test sample: PCB mobile phone antenna board, nickel layer thickness 1-2μm, gold thickness 0.025-0.075μm.

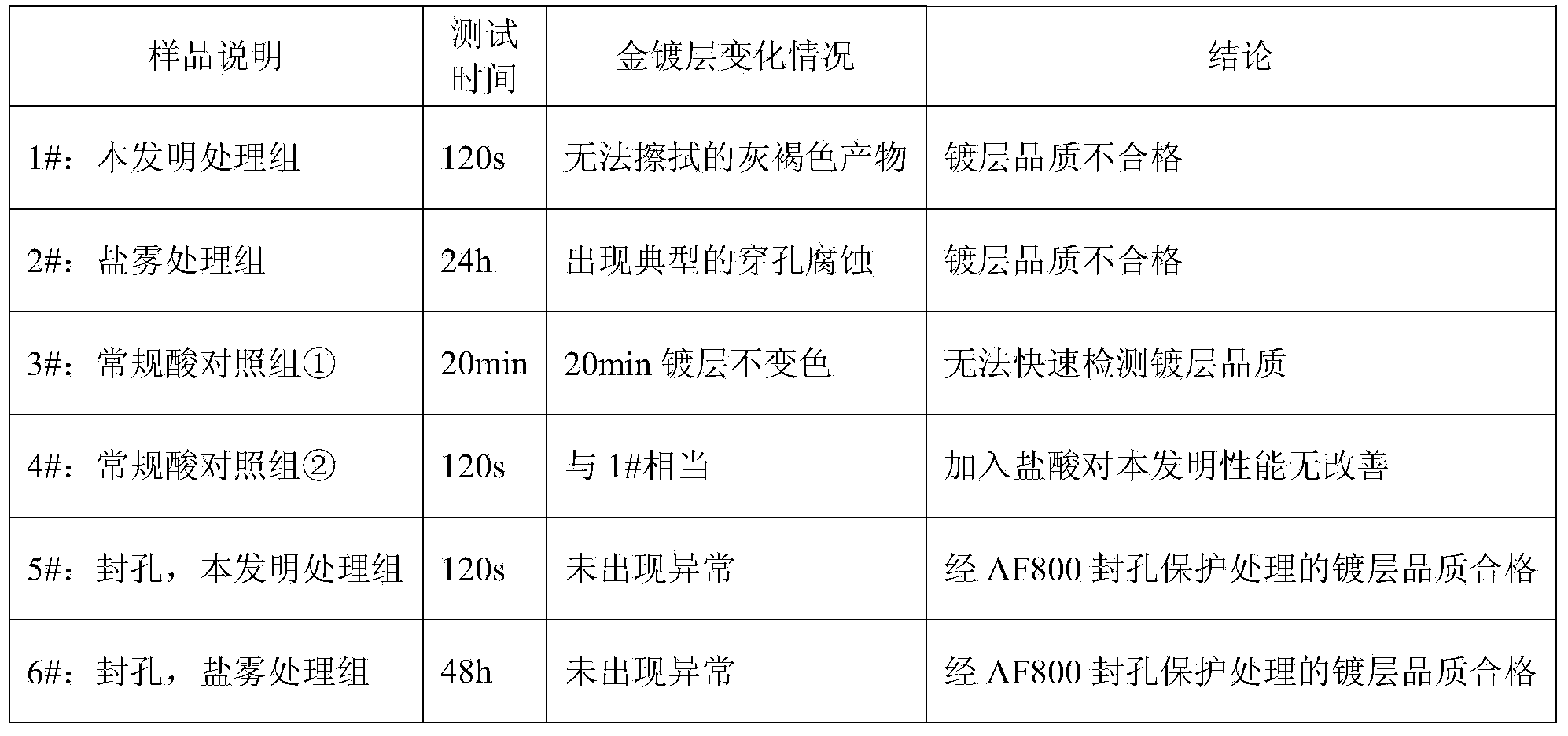

[0051] The processing group settings are as follows:

[0052] 1#: The treatment group of the present invention. Apply 2 to 3 drops of the present invention to cover the area to be detected of the gold coating, wipe the gold coating with a dust-free cloth after several seconds, and observe the discoloration.

[0053] 2#: Salt spray treatment group. Operate according to GB / T10125-1997 s...

Embodiment 2

[0062] Test reagent components (percentage by weight): 1% trifluoroacetic acid, 8% copper sulfate pentahydrate, 2% silver nitrate, and the balance is pure water.

[0063] Conventional acid control components ① (percentage by weight): 1% nitric acid, 8% copper sulfate pentahydrate, 2% silver nitrate, and the balance is pure water.

[0064] Conventional acid control component ② (percentage by weight): 1% nitric acid, 1% trifluoroacetic acid, 8% copper sulfate pentahydrate, 2% silver nitrate, and the balance is pure water.

[0065] Test sample: PCB mobile phone battery board, nickel layer thickness 3-5μm, gold thickness 0.075-0.125μm.

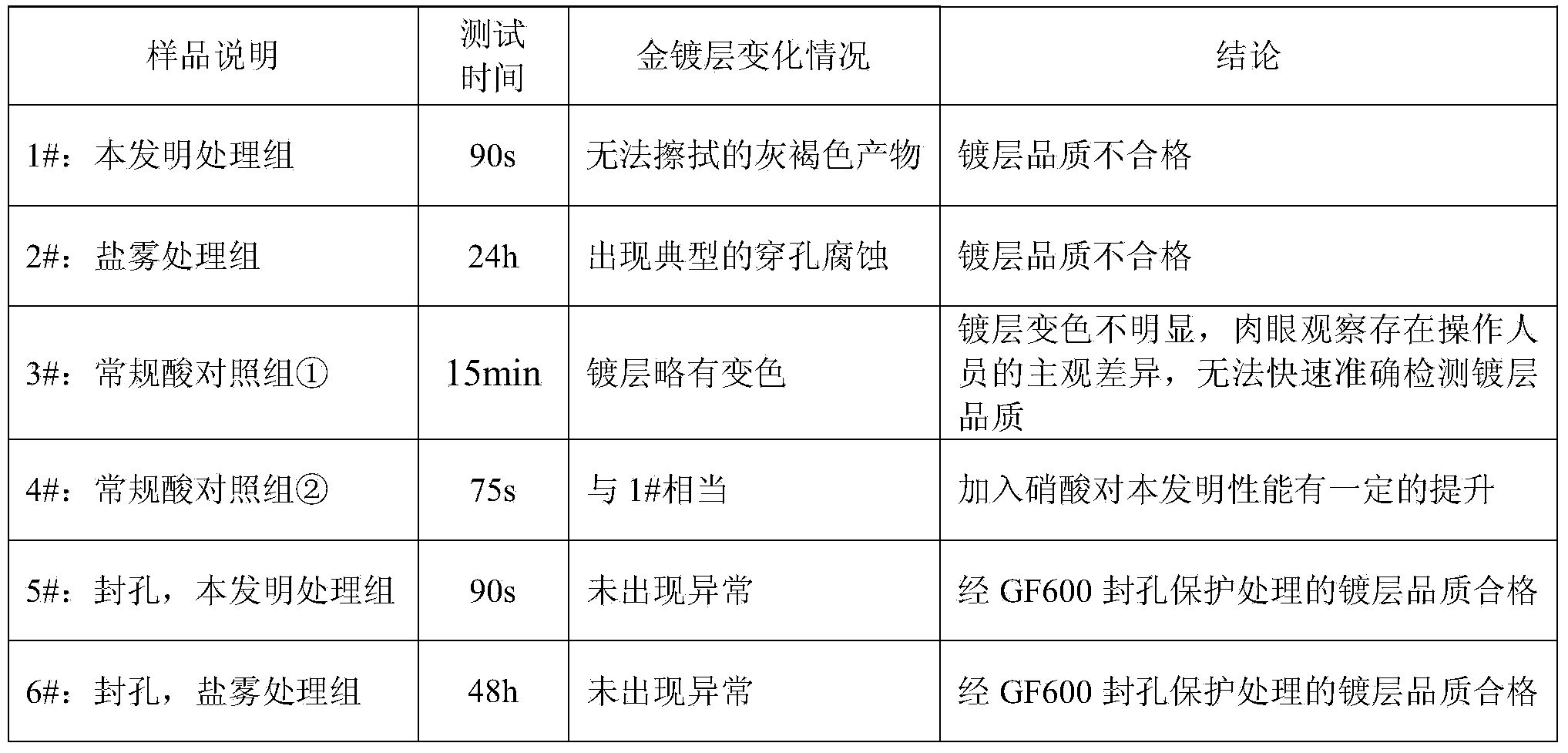

[0066] The processing group settings are as follows:

[0067] 1#: The treatment group of the present invention. Apply 2 to 3 drops of the present invention to cover the area to be detected of the gold coating, wipe the gold coating with a dust-free cloth after several seconds, and observe the discoloration.

[0068] 2#: Salt spray treatment gro...

Embodiment 3

[0077]Test reagent components (percentage by weight): 1% trifluoroacetic acid, 3% copper sulfate pentahydrate, 0.1% silver nitrate, 0.02% EH-6 (Dow, USA), and the balance is pure water.

[0078] Conventional acid control components ① (percentage by weight): 1% sulfuric acid, 3% copper sulfate pentahydrate, 0.1% silver nitrate, 0.02% EH-6 (U.S. Dow), and the balance is pure water.

[0079] Conventional acid control component ② (percentage by weight): 1% sulfuric acid, 1% trifluoroacetic acid, 3% copper sulfate pentahydrate, 0.1% silver nitrate, 0.02% EH-6 (Dow, USA), and The amount is pure water.

[0080] Test sample: PCB optical mode communication board, nickel layer thickness 5-8μm, gold thickness 0.75-1μm.

[0081] The processing group settings are as follows:

[0082] 1#: The treatment group of the present invention. Apply 2 to 3 drops of the present invention to cover the area to be detected of the gold coating, wipe the gold coating with a dust-free cloth after several...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com