Storage battery electrode plate acid spraying and preparation method thereof

A battery and acid-leaching technology, which is applied in the direction of lead-acid battery electrodes, electrode manufacturing, chemical electrode manufacturing, etc., can solve the problems that lead sulfate is not easy to charge, increase resistance, etc., to improve charging acceptance, reduce energy consumption, and improve The effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

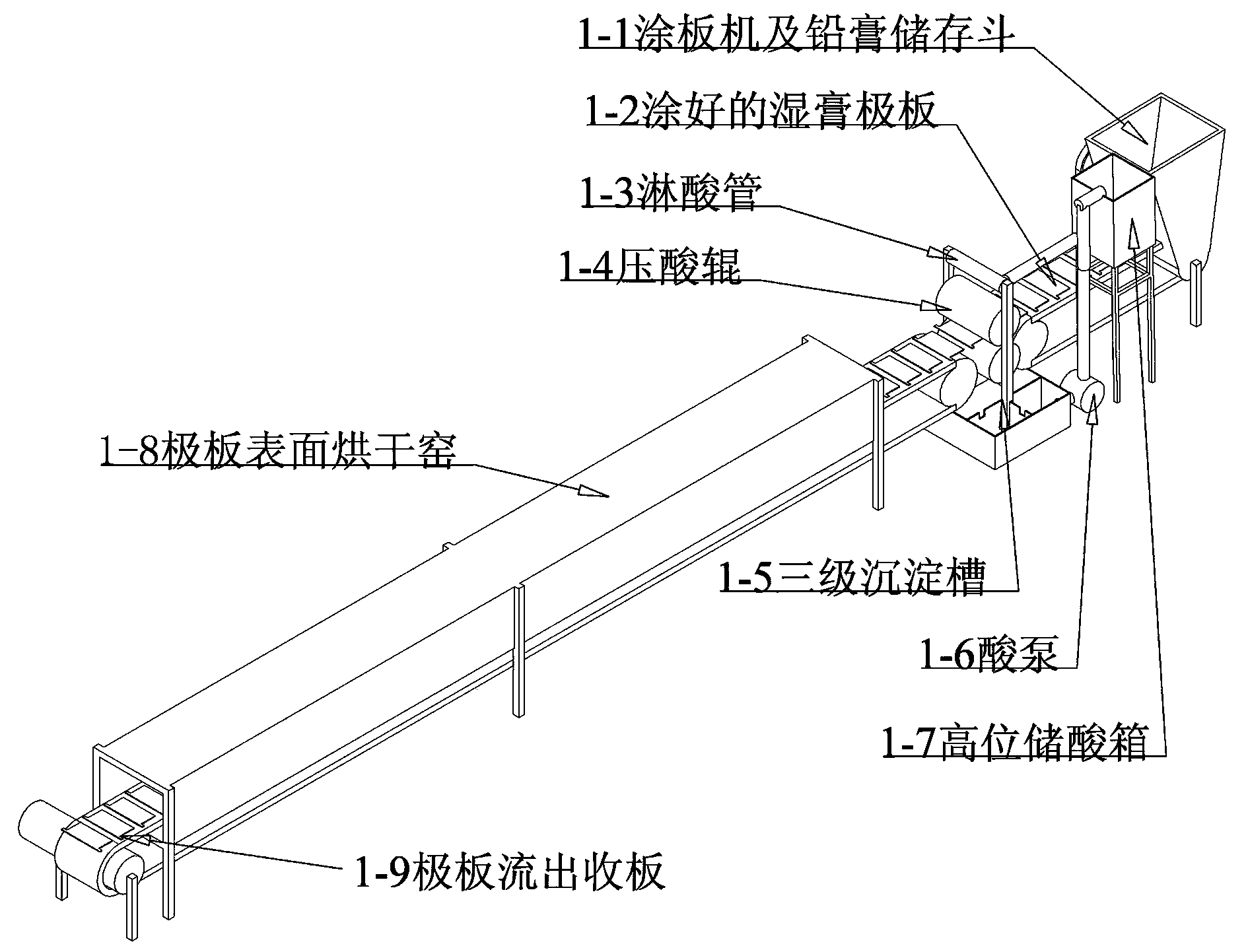

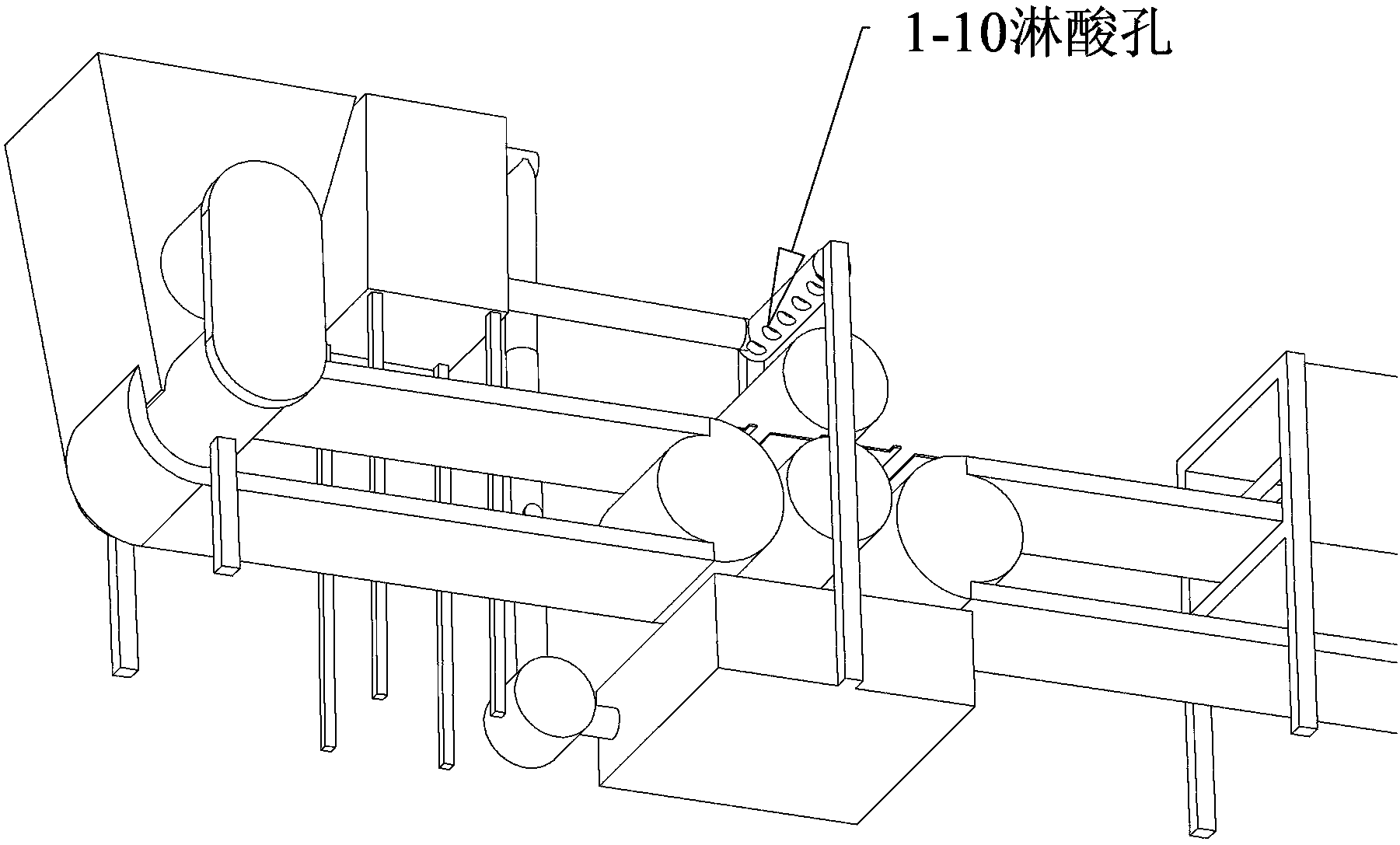

Image

Examples

Embodiment 1

[0032] The present embodiment accumulator electrode plate leaching acid, comprises positive plate leaching acid and negative plate leaching acid, and described positive plate leaching acid comprises the following raw materials in parts by weight: 0.8 part of sodium carboxymethyl cellulose, 0.5 part of polyethylene glycol, sulfuric acid 1 part of sodium, 0.1 part of stannous sulfate, 4 parts of sulfuric acid, and 93.6 parts of water; the negative plate leaching acid includes the following raw materials in parts by weight: 0.8 part of sodium carboxymethyl cellulose, 0.5 part of polyethylene glycol, 1 part of sodium sulfate 0.1 part of stannous sulfate, 8 parts of analytically pure concentrated sulfuric acid, and 88.6 parts of water.

[0033] The acid density of the positive plate in this embodiment is 1.025 g / cm 3 , the acid density of the negative plate is 1.052 g / cm 3 In high temperature seasons, the plate loses water quickly and should adopt this embodiment.

Embodiment 2

[0035] The present embodiment accumulator pole plate leaching acid, comprises positive plate leaching acid and negative plate leaching acid, and described positive plate leaching acid comprises the following raw materials in parts by weight: 0.3 part of sodium carboxymethyl cellulose, 1 part of polyethylene glycol, sulfuric acid 0.5 part of sodium, 0.3 part of stannous sulfate, 5 parts of sulfuric acid, and 92.9 parts of water; the negative plate leaching acid comprises the following raw materials in parts by weight: 0.3 part of sodium carboxymethylcellulose, 1 part of polyethylene glycol, 0.5 part of sodium sulfate 0.3 parts of stannous sulfate, 10 parts of sulfuric acid, and 87.9 parts of water. The sulfuric acid is analytically pure concentrated sulfuric acid with a weight concentration of 96-99%.

[0036] The acid density of the positive plate in this embodiment is 1.032g / cm 3 , the acid density of the negative plate is 1.061 g / cm 3 , The powder falling off the board sur...

Embodiment 3

[0038]The present embodiment accumulator plate leaching acid, comprises positive plate leaching acid and negative plate leaching acid, and described positive plate leaching acid comprises the following raw materials in parts by weight: 0.5 part of sodium carboxymethyl cellulose, 0.7 part of polyethylene glycol, sulfuric acid 2 parts of sodium, 0.2 part of stannous sulfate, 4.5 parts of sulfuric acid, 93.1 parts of water; the negative plate leaching acid comprises the following raw materials in parts by weight: 0.5 part of sodium carboxymethyl cellulose, 0.7 part of polyethylene glycol, 2 parts of sodium sulfate Parts, 0.2 parts of stannous sulfate, 12 parts of sulfuric acid, 84.6 parts of water. The sulfuric acid is analytically pure concentrated sulfuric acid with a weight concentration of 96-99%, wherein Fe content (weight) ≤ 0.0005%, Cl content (weight) ≤ 0.0005%, KMnO 4 Content (weight) ≤ 0.001%.

[0039] The acid density of the positive plate in this embodiment is 1.028 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com