Aqueous multicolor coating composition

A patterned paint, water-based colorful technology, applied in multi-color effect paints, coatings, alginic acid adhesives, etc., can solve the problem of insufficient long-term weather resistance, and achieve improved manufacturing stability, excellent sharpness, and durability. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

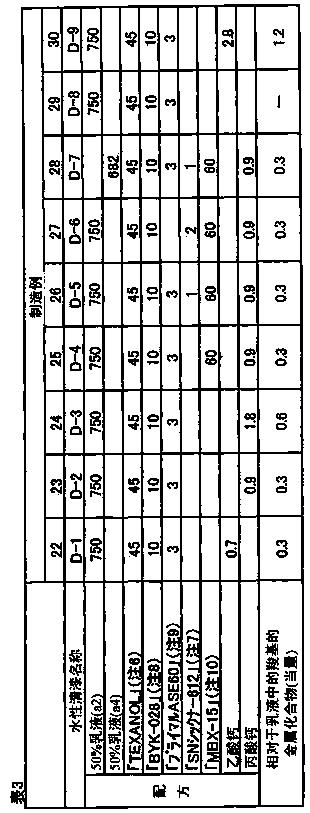

Examples

Embodiment

[0118] The following examples illustrate the present invention in more detail, but the present invention is not limited to these examples. "Parts" and "%" in the following examples represent "parts by mass" and "% by mass", respectively.

[0119]

manufacture example 1

[0120] Production Example 1: Production of Carboxyl and Carbonyl-containing Emulsion (a1) for the Production of Red and White Colored Paint Particle Components

[0121] 285 parts of deionized water and 1 part of "New Cole 707SF" (Note 1) were placed in a 2-liter capacity four-necked flask, and stored at 85°C after nitrogen replacement. 3% of the pre-emulsion obtained by emulsifying the components of the following composition and 41 parts of 123 parts of the initiator aqueous solution obtained by dissolving 3 parts of ammonium persulfate in 120 parts of deionized water were added thereto. After 20 minutes, the remaining pre-emulsion and ammonium persulfate aqueous solution were added dropwise to the flask over 4 hours.

[0122]

[0123] Deionized water 368 parts

[0124] Styrene 150 parts

[0125] Methyl methacrylate 410 parts

[0126] n-butyl acrylate 240 parts

[0127] 2-ethylhexyl acrylate 150 parts

[0128] Diacetone acrylamide 20 parts

[0129] 2-hydroxyethyl acryl...

manufacture example 2

[0134] Production Example 2: Production of core sheath emulsion (a2) containing carboxyl, alkoxysilyl and carbonyl groups for the production of coating film-forming components contained in water-based multicolor paint

[0135] 400 parts of deionized water and 1 part of "New Cole 707SF" (Note 1) were placed in a 3-liter capacity four-necked flask, and stored at 85°C after nitrogen replacement. 3% of the pre-emulsion (for the core) obtained by emulsifying the components of the following composition, and 25 parts of the initiator aqueous solution obtained by dissolving 5 parts of ammonium persulfate in 100 parts of deionized water were added respectively. 20 minutes after the end of the addition, 50% of the residual pre-emulsion (core) and ammonium persulfate aqueous solution was added dropwise to the flask for 3 hours.

[0136]

[0137] Deionized water 300 parts

[0138] Styrene 100 parts

[0139] Methyl methacrylate 250 parts

[0140] n-butyl acrylate 230 parts

[0141] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com