Method for concentrating and recovering noble metals from printed circuit boards of discarded mobile phones and catalysts of discarded cars using discarded nonferrous slag

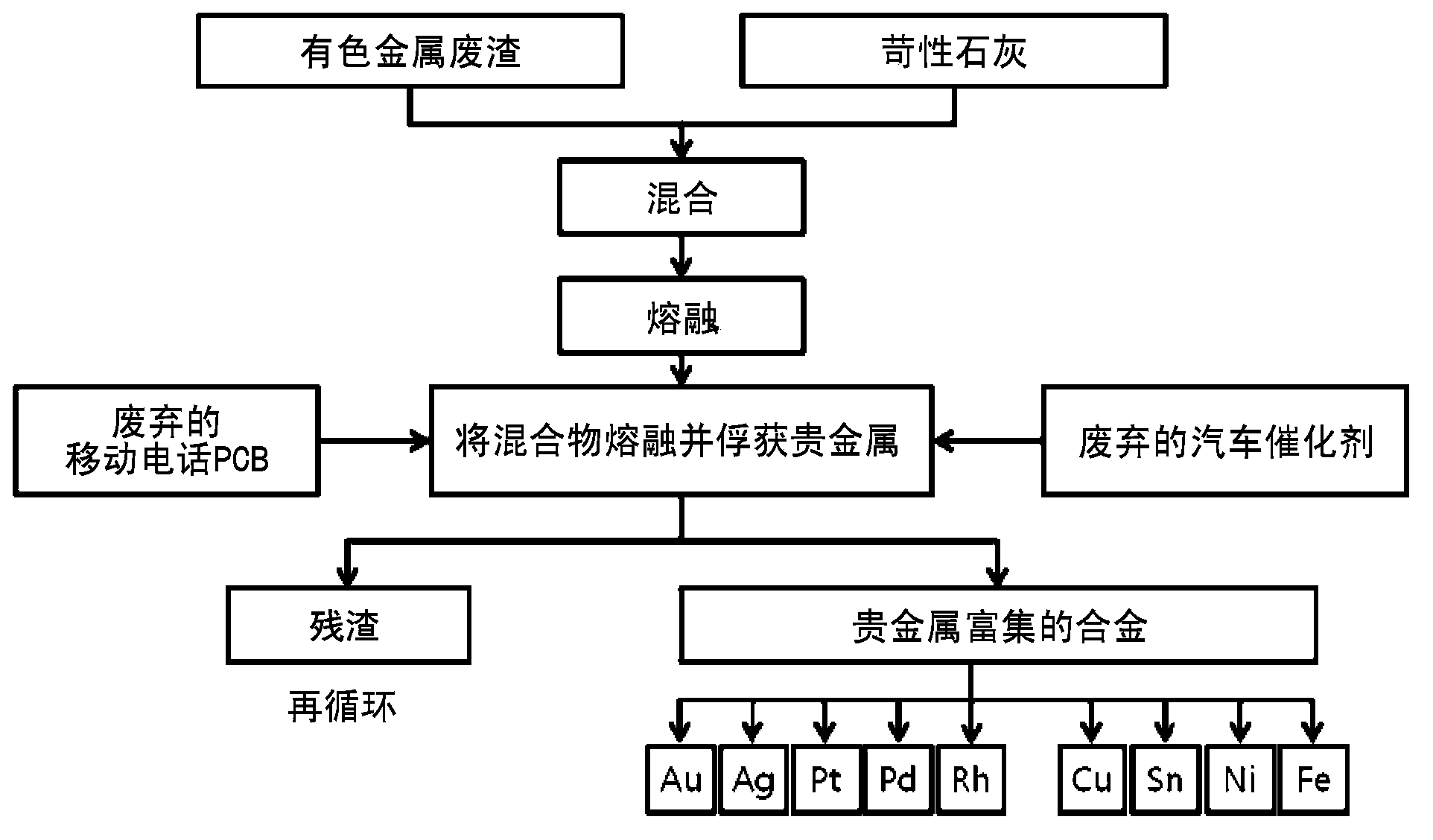

一种汽车催化剂、有色金属的技术,应用在回收贵金属领域,能够解决合金相难分离、增加生产成本、加工时间增加等问题,达到缩短加工时间、能量节约的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

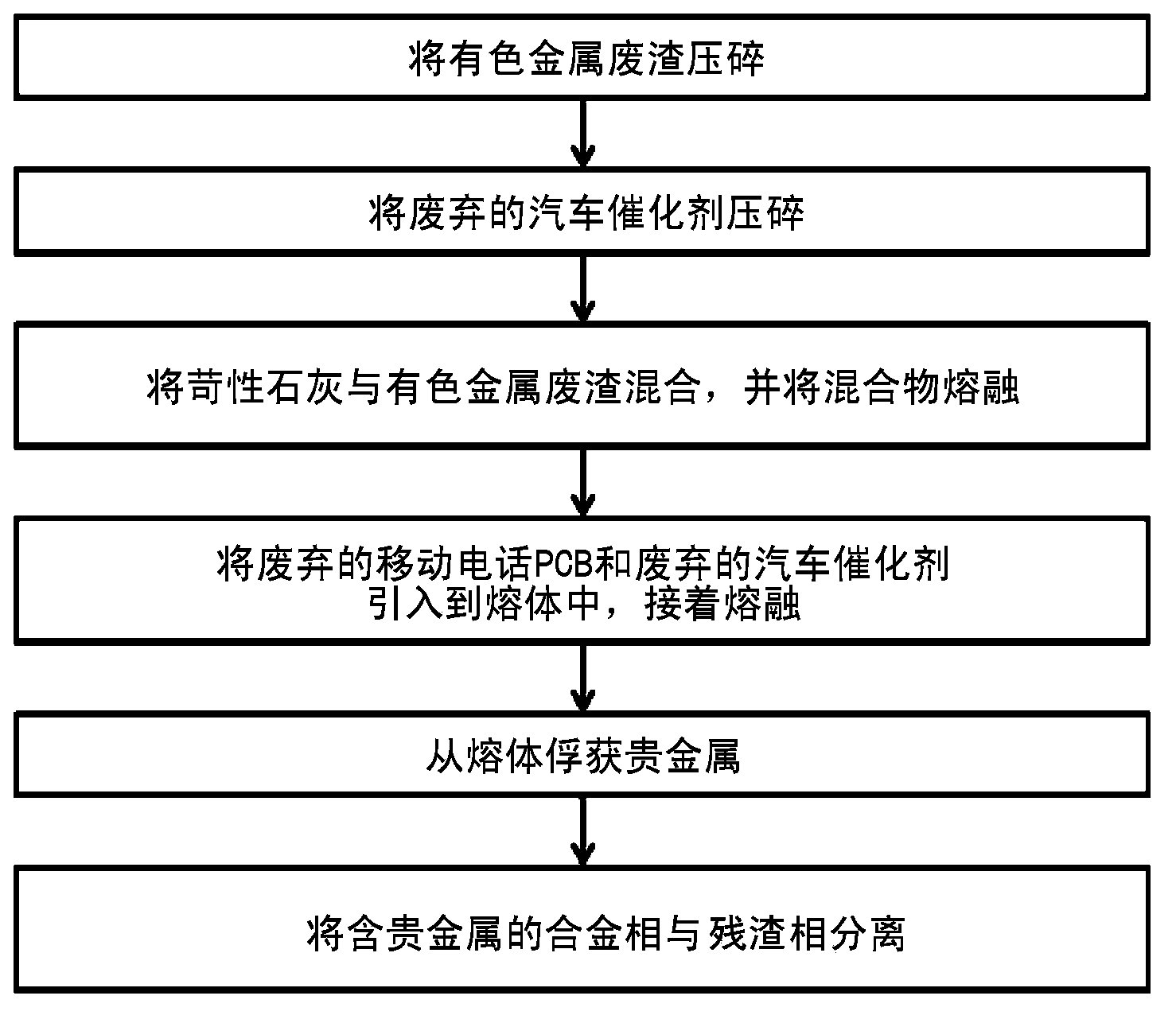

Method used

Image

Examples

Embodiment 1

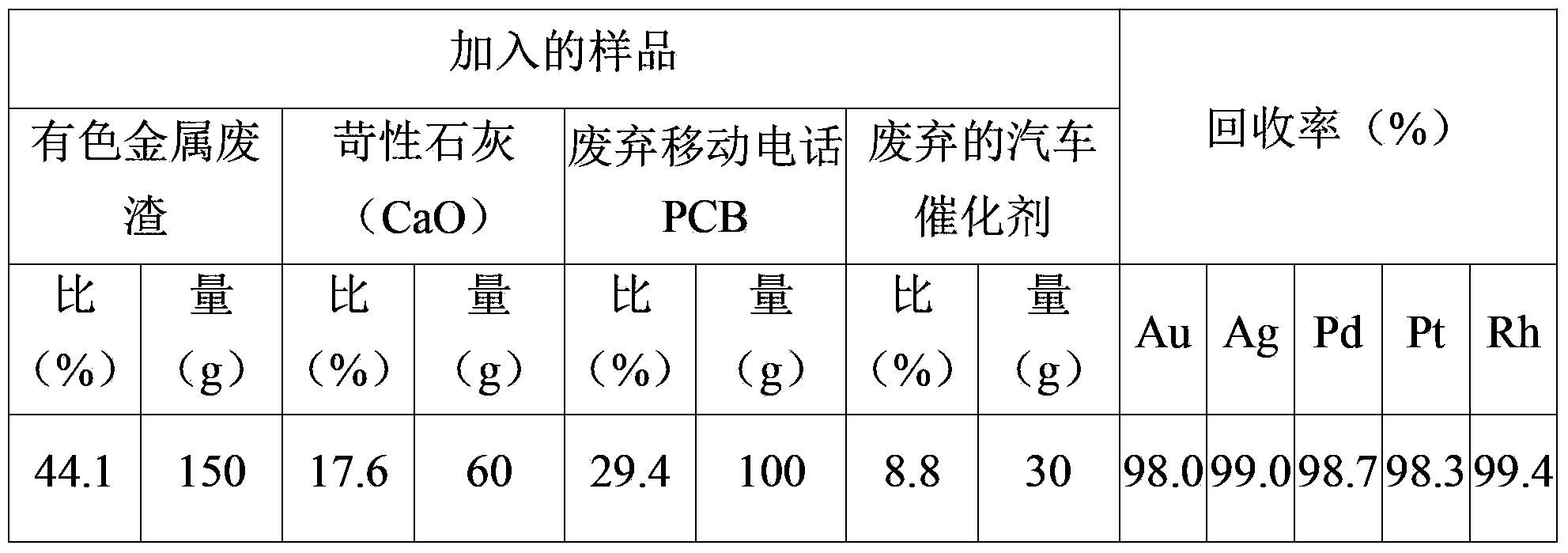

[0044]The non-ferrous metal waste slag and the discarded automobile catalyst are respectively crushed into small particles with a diameter of 0.5-1.0cm. The non-ferrous slag thus crushed is then mixed with caustic lime (CaO), which is a flux as an agent for controlling the composition of the slag. The amount based on 100 parts by weight of non-ferrous metal waste slag was uniformly mixed with 40 parts by weight of caustic lime (CaO) using a V-type mixer (Hanyang Science, Korea), and the mixture was charged into an electric furnace, followed by melting at 1300 °C 20 minutes to obtain a melt. A discarded mobile phone PCB and a crushed discarded auto catalyst were added to the melt thus obtained, followed by melting at 1450° C. for 20 minutes to obtain a melt. At this time, the amount of discarded mobile phone PCBs loaded was 67 parts by weight based on 100 parts by weight of nonferrous metal slag, and the amount of discarded automobile catalyst was 20 parts by weight based on 1...

Embodiment 2

[0047] The non-ferrous metal waste slag and the discarded automobile catalyst are respectively crushed into small particles with a diameter of 0.5-1.0cm. The non-ferrous slag thus crushed is then mixed with caustic lime (CaO), which is a flux as an agent for controlling the composition of the slag. Using a V-type mixer (Hanyang Science, Korea), the amount of caustic lime (CaO) was uniformly mixed with 5 parts by weight based on 100 parts by weight of non-ferrous metal waste slag, and the mixture was charged into an electric furnace, followed by melting at 1300 °C 10 minutes to obtain a melt. A discarded mobile phone PCB and a crushed discarded auto catalyst were added to the melt thus obtained, followed by melting at 1300° C. for 40 minutes to obtain a melt. At this time, the amount of waste mobile phone PCB loaded was 50 parts by weight based on 100 parts by weight of nonferrous metal residue, and the amount of discarded automobile catalyst was 15 parts by weight based on 10...

Embodiment 3

[0050] Crush non-ferrous metal waste slag and waste auto catalyst into small particles with a diameter of 1.0-1.5cm and 0.5-1.0cm, respectively. The non-ferrous slag thus crushed is then mixed with caustic lime (CaO), which is a flux as an agent for controlling the composition of the slag. 25 parts by weight of caustic lime (CaO) was uniformly mixed in an amount based on 100 parts by weight of non-ferrous metal waste slag using a V-type mixer (Hanyang Science, Korea), and the mixture was charged into an electric furnace, followed by melting at 1350 °C 15 minutes to obtain a melt. A discarded mobile phone PCB and a crushed discarded auto catalyst were added to the melt thus obtained, followed by melting at 1400° C. for 30 minutes to obtain a melt. At this time, the amount of waste mobile phone PCB loaded was 50 parts by weight based on 100 parts by weight of nonferrous metal waste residue, and the amount of waste automobile catalyst loaded was 25 parts by weight based on 100 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com