Radiation-proof clothes

A technology of anti-radiation clothing and anti-radiation layer, which is applied in the field of anti-radiation clothing, can solve the problems of poor anti-radiation effect of anti-radiation clothing, unsuitability for radiation protection products, and inability to protect the whole body, so as to prevent the weakening of anti-radiation effect and improve the anti-radiation effect. Radiation effect, effect of improving radiation protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

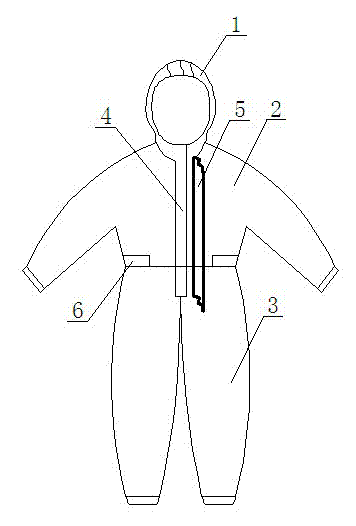

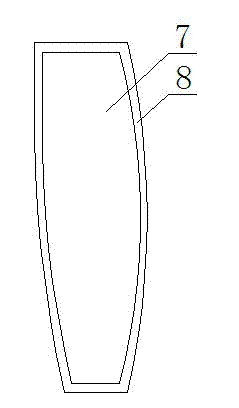

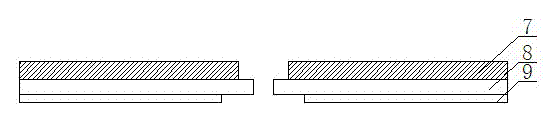

[0023] A kind of anti-radiation clothing, comprising coat 2, trousers 3 and hat 1, a zipper is arranged in the middle part of the coat 2, the zipper is a zipper made of high-density polyester, one side of the zipper is provided with a second One protective layer 4, the other side is provided with the second protective layer 5, and the inner side of the jacket is provided with an adjustment belt 6, and the jacket 2, the trousers 3, the hat 1, the first protective layer 4, and the second protective layer 5 are all three layers Structure, from outside to inside are heavy metal anti-radiation layer 7, carrier layer 8 and silver fiber layer 9 respectively, and described carrier layer is made of polystyrene, and its thickness is 2-5mm; The lengths of the three structural layers of the forming part are not equal, the length of the carrier layer is greater than the length of the heavy metal radiation protection layer, the length of the heavy metal radiation protection layer is greater ...

Embodiment 2

[0026] A kind of anti-radiation clothing, its difference with embodiment 1 is that described heavy metal anti-radiation layer can also be the molybdenum anti-radiation layer that heavy metal molybdenum and polystyrene form, wherein the mass content of heavy metal molybdenum is 92%.

[0027] The difference between the manufacturing method and Example 1: the polystyrene thermoplastic elastomer is processed on common equipment such as a hot roll mill and an internal mixer, and the processing temperature is controlled at 140-200 ° C; after the polystyrene is softened, the Molybdenum metal powder with a particle diameter of less than 15 microns is added to one side of the polystyrene, and the sheet is cooled to form a molybdenum radiation protection layer; after cooling, silver fibers are pressed into the other side of the polystyrene to form a silver fiber layer.

Embodiment 3

[0029] A kind of anti-radiation clothing, the difference between it and embodiment 1 is that the heavy metal anti-radiation layer is a tungsten-molybdenum anti-radiation layer composed of a mixture of tungsten and molybdenum and polystyrene, wherein the volume ratio of heavy metal tungsten and heavy metal molybdenum is 1:1 .

[0030] The difference between the manufacturing method and Example 1: First, mix the tungsten metal powder and the molybdenum metal powder with a particle diameter of less than 15 microns in a ratio of 1:1 by volume, and stir evenly; then knead the polystyrene thermoplastic elastomer on a hot roller Machine, internal mixer and other common equipment for processing, the processing temperature is controlled at 140-200 °C; after the polystyrene is softened, metal powder mixed with tungsten and molybdenum is added to one side of it, and pressed into tablets to cool and form, forming tungsten-molybdenum Radiation protection layer; after cooling, silver fibers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com