Catalyst with hydrogenation catalysis effect, preparation method and application of catalyst and hydroisomerization method

A technology of catalysts and additives, applied in the field of catalysts and their preparation, can solve the problem that the hydrogenation catalytic activity of the catalyst needs to be further improved, and achieve the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

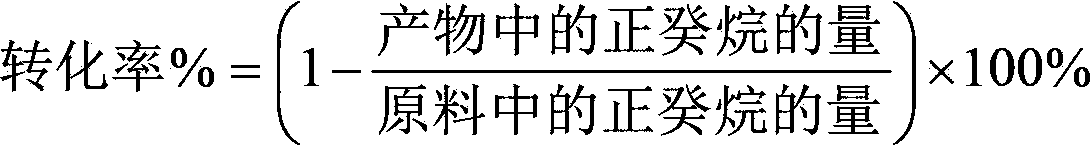

Examples

preparation example Construction

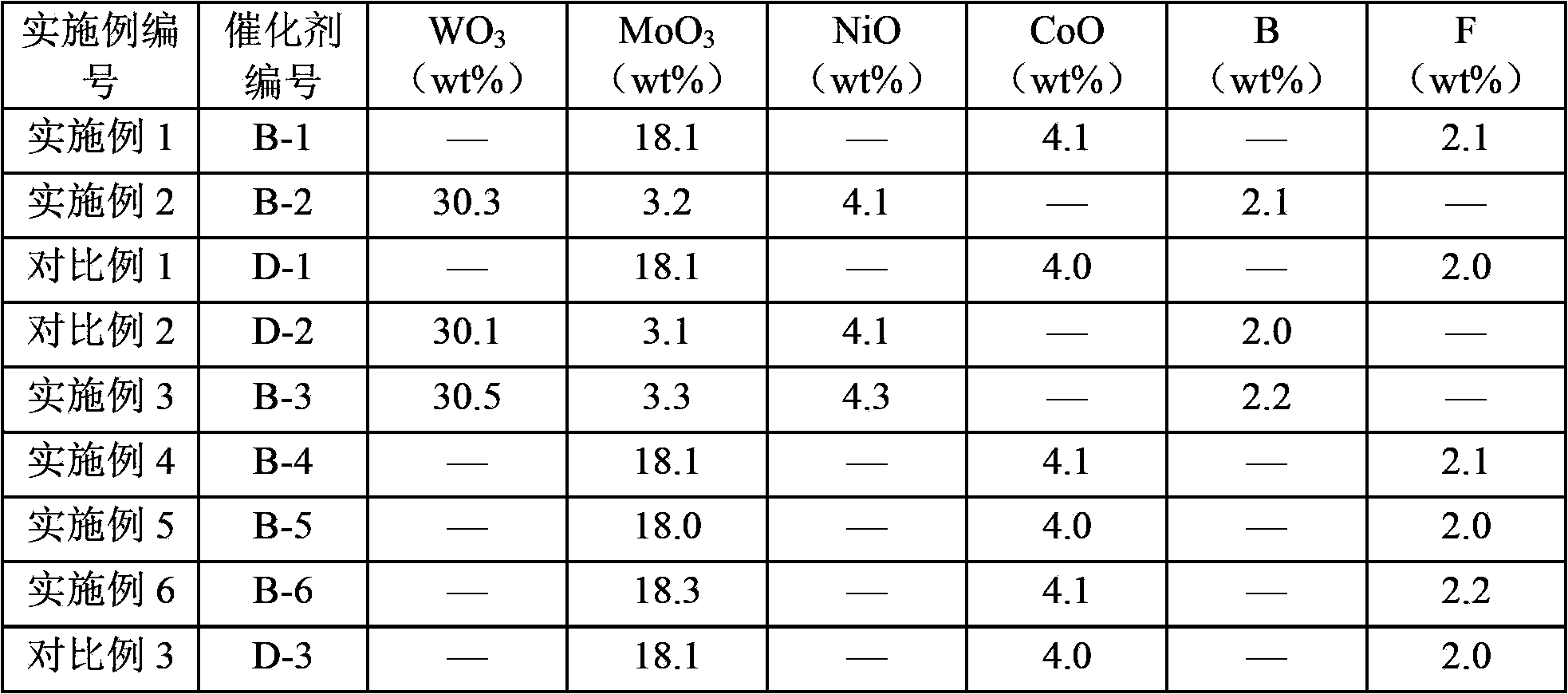

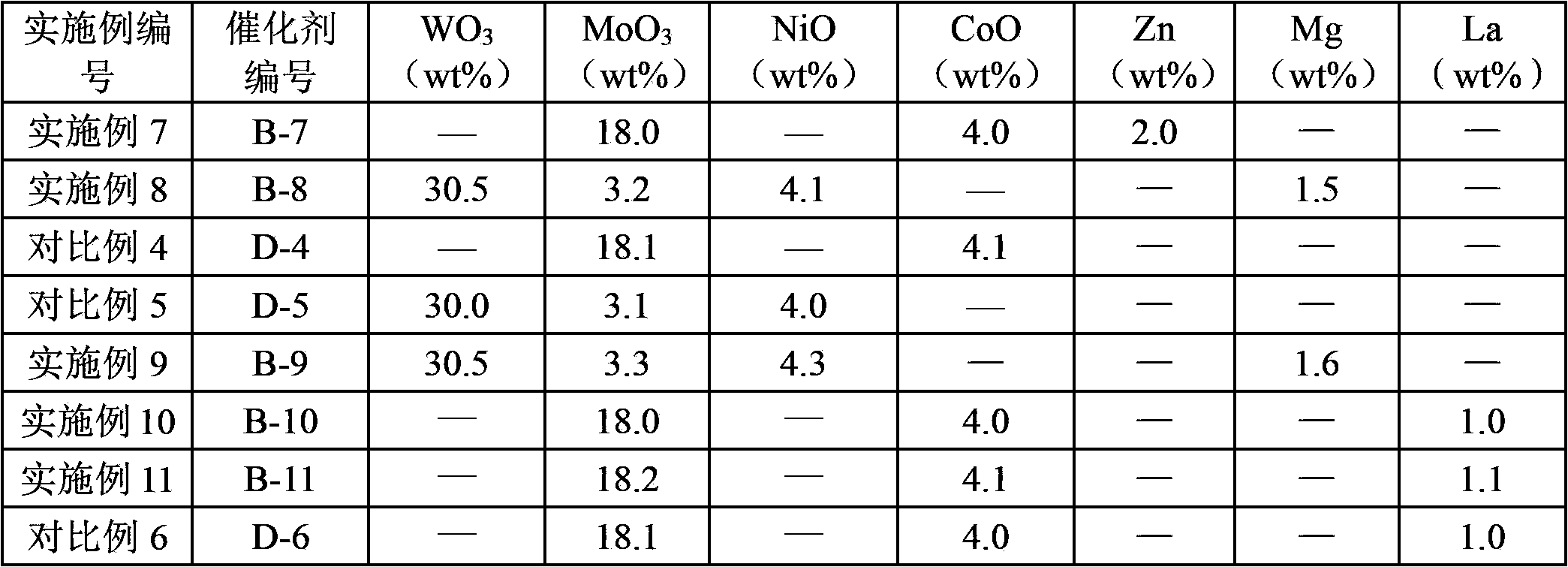

[0026] In the catalyst obtained according to the preparation method of the present invention, the contents of the metal elements of Group VIB, metal elements of Group VIII and elements used as promoters can be properly selected according to the specific application of the catalyst. Generally, the introduction amount of the Group VIB metal element, the Group VIII metal element and the element as an auxiliary agent on the shaped porous carrier is such that, based on the total amount of the catalyst, the shaped The content of the porous carrier can be 30-88.5% by weight, preferably 43-88.5% by weight, more preferably 52-85% by weight; in terms of oxides, the content of Group VIB metal elements can be 10-50% by weight, It is preferably 10-45% by weight, more preferably 12-40% by weight; in terms of oxides, the content of Group VIII metal elements can be 1-10% by weight, preferably 1-7% by weight, more preferably 2- 5% by weight; based on the element, the content of the element as ...

preparation example 1

[0086] (1) Synthesize SAPO-11 molecular sieve according to the method of Example 16 in US4440871. The specific steps are:

[0087] Mix 144.0g of pseudo-boehmite (commercially purchased from the Catalyst Plant of Sinopec Changling Refining and Chemical Company, with a dry basis content of 71% by weight) and 440.0g of distilled water, then add 230.6g of phosphoric acid (85% by weight), and stir evenly. Mixture P1 is obtained.

[0088] 649.2 g of a 40% by weight aqueous solution of hydroxytetra-n-butylamine and 26.0 g of fumed silica gel (with a silicon oxide content of 92.8% by weight and a water content of 7.2% by weight) were evenly mixed to obtain a mixture P2.

[0089]The mixtures P1 and P2 were uniformly mixed, and 102.0 g of di-n-propylamine was added with stirring to obtain a reaction mixture. Put the reaction mixture into a polytetrafluoroethylene-sealed reaction kettle, crystallize at 200°C for 24 hours, filter and wash the solid product to neutrality, and dry the sol...

preparation example 2

[0092] 75 grams of ZSM-5 molecular sieves (commercially purchased from Catalyst Plant of Sinopec Changling Refining and Chemical Company, SiO 2 / Al 2 o 3 The molar ratio is 50, and the dry basis content is 80% by weight), 1125 grams (on a dry basis) of pseudoboehmite (commercially purchased from Shandong Aluminum Factory, the trade name is SD powder, and the dry basis content is 69% by weight), 1000 grams of silica sol (commercially purchased from Qingdao Ocean Chemical Factory, with a silicon dioxide content of 30% by weight) and 45 grams of scallop powder were mixed evenly, extruded into clover-shaped strips with a circumscribed circle diameter of 1.6 mm, and the extruded molding Dry at 120°C for 3 hours, and bake at a temperature of 550°C for 3 hours to prepare a porous carrier S2, wherein, based on the total amount of the porous carrier, the content of mesoporous molecular sieves is 5.0% by weight, and the content of silicon oxide The content of alumina is 20.0% by weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com