Preparation method for silver nanocubes

A cube and silver nanotechnology, applied in the direction of nanotechnology, can solve the problems of uneven particle size control, long reaction time, poor repeatability, etc., and achieve the effect of uniform shape, high repeatability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

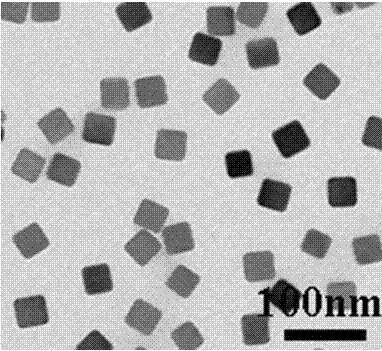

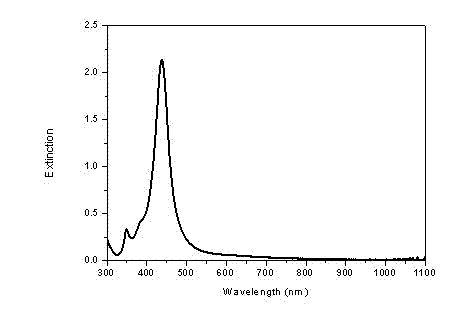

[0029] Step 1: Add 5mL ethylene glycol into a 50mL three-necked flask, heat it to 150°C with an oil bath, and keep the temperature constant at 150°C, then add 0.06mL 3mM sodium hydrosulfide ethylene glycol solution, 0.5mL 3mM HCl Diol solution, 1.25mL 20mg / mL PVP solution in ethylene glycol, and 0.4mL 200mM silver trifluoroacetate solution in ethylene glycol. The extent of the reaction was monitored by UV-visible absorption spectrum. When the UV-visible absorption peak appeared near 350 nm and 435 nm, the flask was taken out and immersed in an ice-water bath to terminate the reaction. After repeated centrifugal washing with ethanol and water, the nano-seeds Dispersed in water for preservation, the concentration of silver seeds is 9×10 20 cells / mL, with an average side length of 35 nm;

[0030] Step 2: Add 1.25mL ethylene glycol into a 10mL beaker, heat it to 150 ℃ with an oil bath, then add 0.3mL 20mg / mL PVP ethylene glycol solution, 200μL prepared in the first step with an a...

Embodiment 2

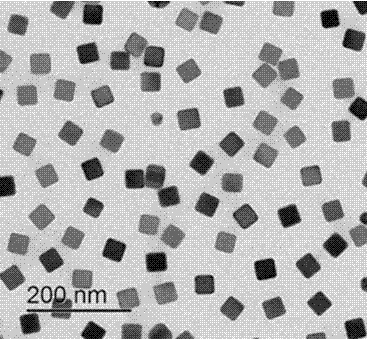

[0032] Add 1.25mL of ethylene glycol into a 10mL beaker and heat to 150°C with an oil bath. Then add 0.3 mL 20mg / mL PVP ethylene glycol solution, the average side length of 100 μ L embodiment 1 prepared in the first step is the silver nanocube seed of 35 nm and the ethylene glycol solution of 100 μ L 200mM silver nitrate, react after carrying out 3 h The flask was taken out and immersed in an ice-water bath to terminate the reaction, and silver nanocubes with an average side length of 56 nm were obtained, washed repeatedly with ethanol and water, and dispersed in water for storage.

Embodiment 3

[0034] Step 1: Add 5mL of ethylene glycol into a 50mL three-neck flask, heat it to 150°C with an oil bath, and keep the temperature constant at 150°C. Then add 0.06mL 3mM potassium sulfide ethylene glycol solution, 0.5mL 3 mM HCl ethylene glycol solution, 1.25mL 20mg / mL PVP ethylene glycol solution and 0.4mL 200mM silver trifluoroacetate ethylene glycol solution, and use UV-visible absorption The extent of the reaction is monitored by spectroscopy. When the ultraviolet-visible absorption peaks appear around 350 nm and 435 nm, the flask is taken out and immersed in an ice-water bath to terminate the reaction. After repeated centrifugation and washing with ethanol and water for several times, the nano-seeds are dispersed in water for storage , the concentration of silver seeds is 9х10 20 cells / mL, with an average side length of 35 nm;

[0035] Step 2: Add 1.25mL ethylene glycol into a 10mL beaker, heat it to 150 ℃ with an oil bath, then add 0.3mL 20 mg / mL PVP ethylene glycol so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com