Making method of axis neck of 9-12% Cr steel turbine rotor and axis neck produced by the method

A manufacturing method and turbine technology, applied in the direction of manufacturing tools, furnace types, mechanical equipment, etc., can solve the problems of insufficient joint toughness and fatigue strength, and achieve the effect of improving joint toughness, fatigue characteristics, and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

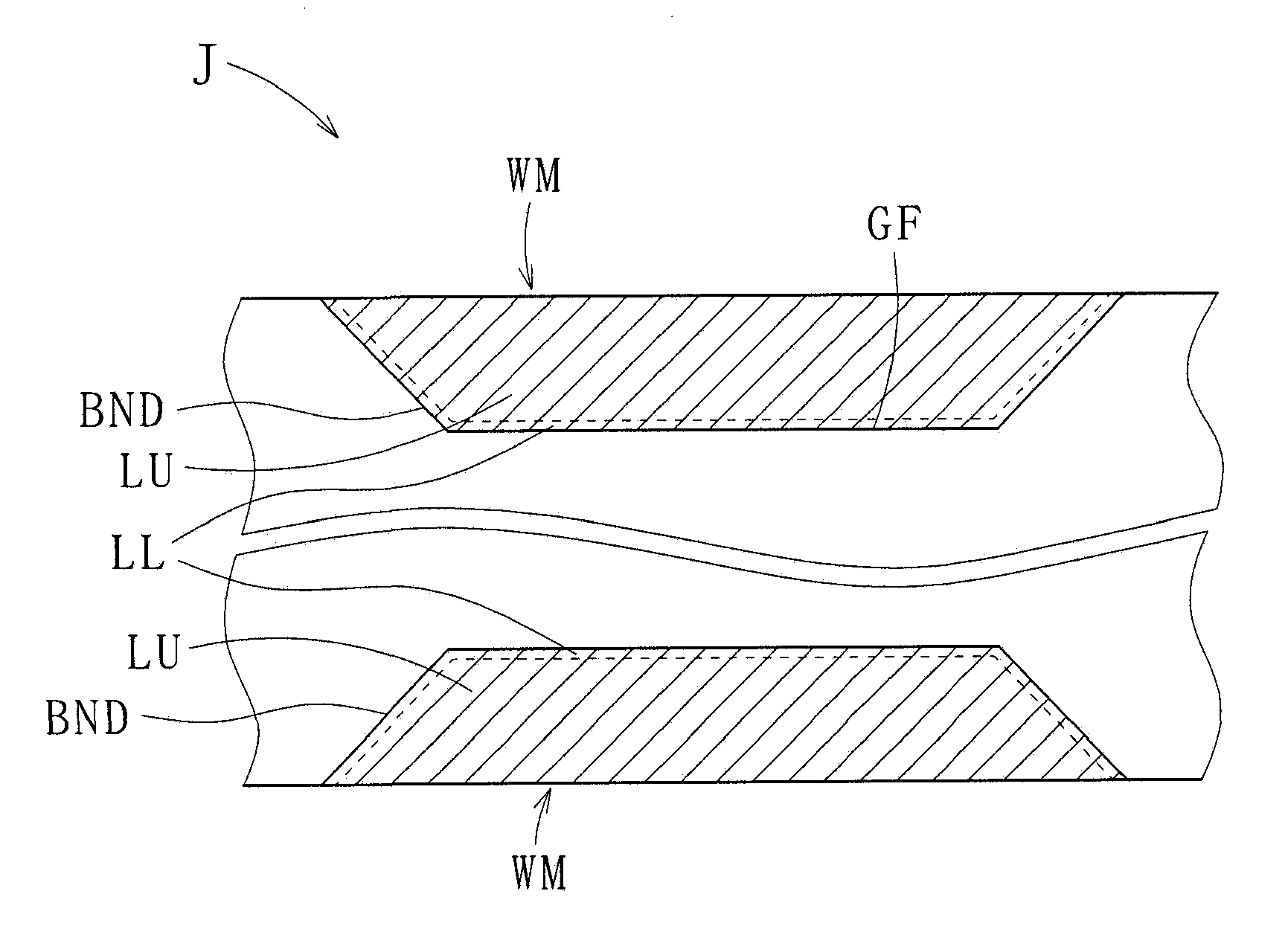

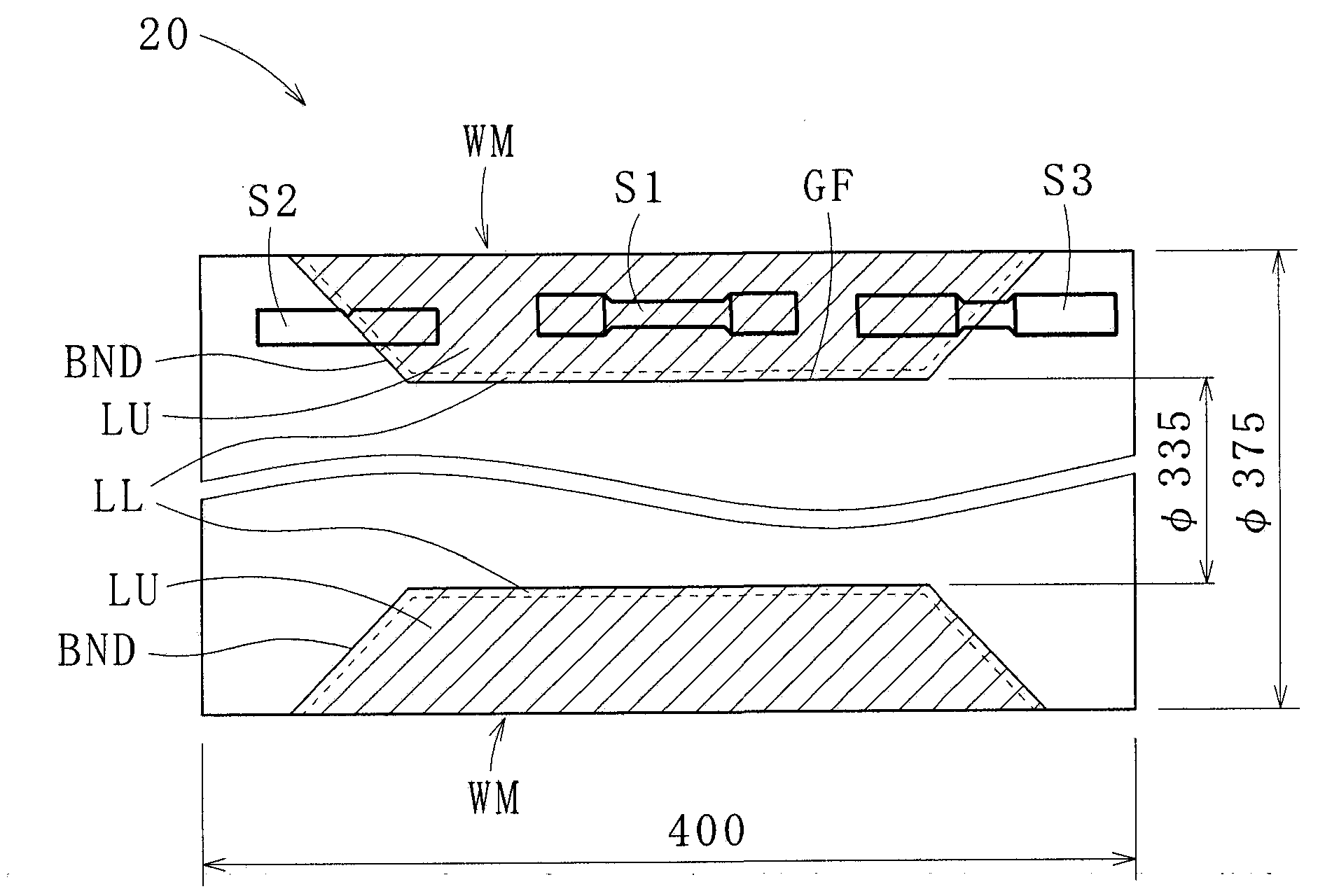

[0040] Next, an embodiment of the present invention will be described with reference to the drawings for understanding of the present invention. It should be noted that, in each figure, parts not relevant to the description may be omitted from illustration. In addition, the ratio (%) of the component composition of a metal represents % by weight.

[0041] The inventors of the present invention experimented under various welding construction conditions combining the component composition of the weld deposit welded to the journal with the welding material, the welding method, and the subsequent heat treatment for stress relief. As a result, it was found that especially by including a small amount of alloy components such as Ni and / or Cr in the weld deposit metal in the inner layer of the journal, and further containing a small amount of V component, it is possible to suppress the joint portion (the weld deposit part and the weld deposit part) 9-12%Cr steel with high fatigue cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap