Low-carbon hydrocarbon aromatization method

A low-carbon hydrocarbon and aromatization technology, applied in chemical instruments and methods, organic chemistry, molecular sieve catalysts, etc., can solve problems such as poor reaction stability, and achieve good technical effects by alleviating frequent reactor switching and catalyst regeneration , Improve the effect of effective active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

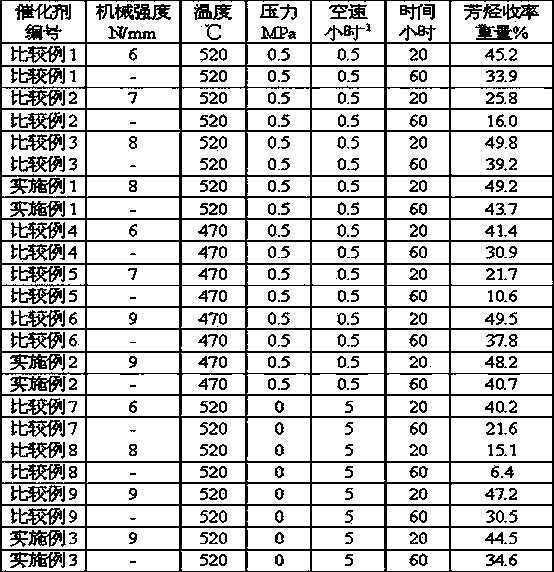

Examples

Embodiment 1

[0030] The binder-free NaZSM-5 molecular sieve (silicon-alumina ratio of 120) was calcined at 550° C. for 4 hours to remove the template. Afterwards, the obtained material was exchanged three times with 0.8 mol / L ammonium nitrate solution at 80°C, washed twice with water, and dried at 120°C for 10 hours to obtain ammonia-type molecular sieves. Ni and P species (sourced from ammonium phosphate) were loaded onto ammonia-type molecular sieves by equal-volume impregnation method, and the loading amounts were 3% and 1% of the weight of the precursor, respectively, dried and calcined.

[0031]

Embodiment 2

[0042] Binder-free NaZSM-5 molecular sieve (silicon-alumina ratio: 70) was calcined at 550°C for 4 hours to remove the template. Afterwards, the obtained material was exchanged three times with 0.8 mol / L ammonium nitrate solution at 80°C, washed twice with water, and dried at 120°C for 10 hours to obtain ammonia-type molecular sieves. Zn, P and F species (sourced from ammonium phosphate and ammonium fluoride, respectively) were loaded onto ammonia-type molecular sieves by equal volume impregnation method, and the loading amounts were 5%, 1% and 1% of the weight of the precursor, respectively, dried and calcined.

[0043]

Embodiment 3

[0054] Binder-free NaZSM-5 molecular sieves (silicon-aluminum ratio of 20) were calcined at 550°C for 4 hours to remove the template. Afterwards, the obtained material was exchanged three times with 0.8 mol / L ammonium nitrate solution at 80°C, washed twice with water, and dried at 120°C for 10 hours to obtain ammonia-type molecular sieves. Fe, Ga, P, and F species (sourced from ammonium phosphate and ammonium fluoride, respectively) were loaded onto ammonia-type molecular sieves by equal volume impregnation method, and the loading amount was 1% of the weight of the precursor, dried and calcined.

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com