A method for deep adsorption desulfurization of oil products

An oil and adsorbent technology, applied in chemical instruments and methods, refining hydrocarbon oil, treating hydrocarbon oil, etc., can solve the problems of unstable organic framework, low sulfur removal rate, long adsorption time, etc. Low mass diffusion efficiency, enhanced mass transfer diffusion performance, and the effect of increasing active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

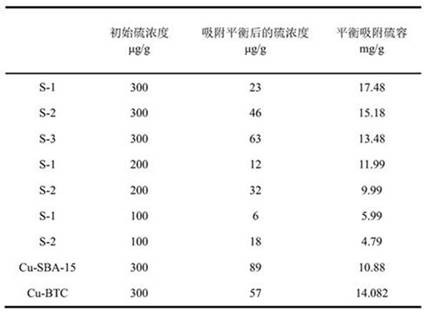

Embodiment 1

[0026] Dissolve P123 in HCl solution with a concentration of 1M, stir to fully dissolve it, and obtain solution (1); dissolve the silicon source shown in formula (I) in ethanol, stir and dissolve it fully, and obtain a silicon source with a concentration of 1M solution; the silicon source solution is added dropwise to the solution (1), and a copper nitrate solution with a concentration of 0.05M is added, so that the molar ratio of the silicon source, soft template agent, and metallic copper in the solution system is 3:0.8:1, Continue to stir for 8 hours; transfer the obtained mixture into a stainless steel reaction kettle with polytetrafluoroethylene, react at 100°C for 24 hours, naturally cool to room temperature after the reaction, filter, and use ethanol to remove the soft template agent in the filtered product Reflux extraction, the Cu / mesoporous organosilica nanotube desulfurization adsorbent of this example was obtained, wherein Cu accounted for 6.4 wt% of the mass of the...

Embodiment 2

[0028] Dissolve P123 in HCl solution with a concentration of 1.5M, stir to fully dissolve it, and obtain solution (1); Silicon source solution; Add the silicon source solution dropwise to the solution (1), and add a copper nitrate solution with a concentration of 0.05M, so that the molar ratio of the silicon source, soft template agent, and metallic copper in the solution system is 3:0.8: 0.5, continue to stir for 8 hours; transfer the resulting mixture into a stainless steel reactor with polytetrafluoroethylene, react at 110°C for 20 hours, naturally cool to room temperature after the reaction, filter, and use ethanol to filter the soft template in the filtered product reflux extraction to obtain the Cu / mesoporous organosilica nanotube desulfurization adsorbent of this embodiment, wherein Cu accounts for 4.2 wt% of the mass of the adsorbent, which is marked as number S-2.

Embodiment 3

[0030] Dissolve P123 in HCl solution with a concentration of 1.5M, stir to fully dissolve it, and obtain solution (1); Silicon source solution; Add the silicon source solution dropwise to the solution (1), and add a silver nitrate solution with a concentration of 0.03M, so that the molar ratio of the silicon source, soft template agent, and silver metal in the solution system is 3:0.8: 0.8, continue to stir for 8 hours; transfer the resulting mixture into a stainless steel reactor with polytetrafluoroethylene, react at 100°C for 30 hours, naturally cool to room temperature after the reaction, filter, and use ethanol to filter the soft template in the filtered product The Ag / mesoporous organosilica nanotube desulfurization adsorbent of this embodiment was obtained by reflux extraction, wherein Ag accounted for 5.9 wt% of the mass of the adsorbent, which was recorded as number S-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com