Continuous diazotization production process of aromatic amine

A production process, technology of aromatic amines, applied in the field of continuous diazotization production process of aromatic amines, can solve the problems of low production efficiency, poor working environment, unstable reaction conditions, etc., to reduce batch difference and improve utilization rate , The effect of shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

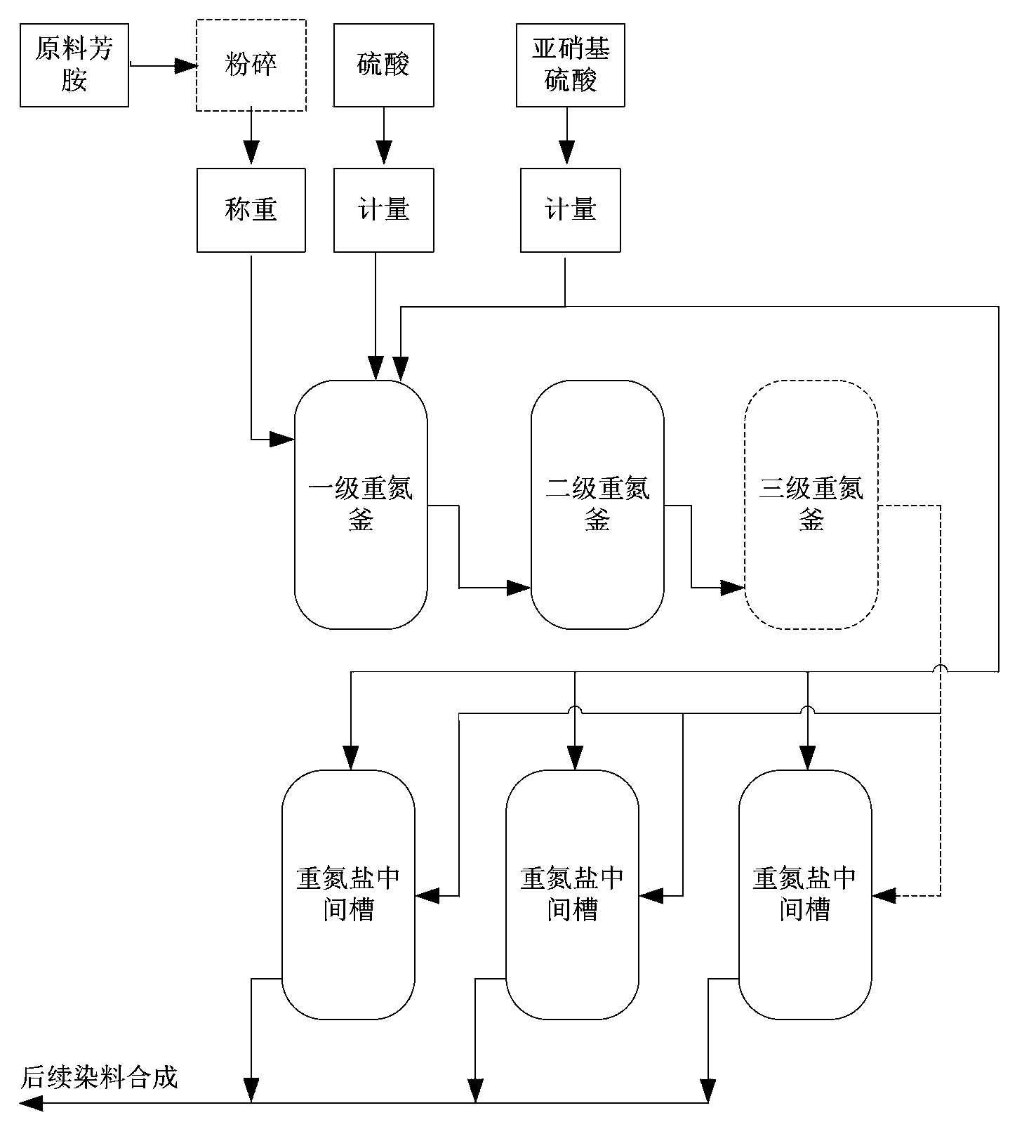

Embodiment 1

[0024] The continuous diazo method of two kettles in series is adopted, and the effective volume of a single kettle is 3M3 , with a cooling jacket outside and a cooling coil inside, the liquid level of the single-pot reaction is set to about 90% of the effective volume, and the reaction residence time is about 3 hours.

[0025] Add the previous batch of diazonium salt solution synthesized as base material into two diazonium reaction kettles, the amount added is 60% of the full liquid level, start stirring, and feed frozen brine into the jacket and cooling coil, The powdery 2,4-dinitro-6-bromoaniline raw material is added to the silo of the weighing feeding system, the feeding speed is controlled by the motor speed of the screw feeder, and added to the primary weight after being detected by the weight-loss type load cell. The feed rate in the nitrogen reactor is 180kg / h. At the same time, according to the feed molar ratio of aromatic amine, sulfuric acid, and nitrosyl sulfuric a...

Embodiment 2

[0034] The continuous diazo method of three kettles in series is adopted, and the effective volume of a single kettle is 3m 3 , The first and second-stage kettles are equipped with cooling jackets and cooling coils inside; the third-stage kettles are equipped with jackets; the reaction liquid level of the single kettle is set to about 90% of the effective volume, and the reaction residence time is about 2.5 hours.

[0035] Add the previous batch of synthesized diazonium salt solution as base material into three diazonium reaction kettles, the amount added is 60% of the full liquid level, start stirring, and feed frozen brine into the jacket and cooling coil. The powdered 2,6-dichloro-4-nitroaniline raw material is added to the silo of the weighing feeding system, the feeding speed is controlled by the motor speed of the screw feeder, and added to the primary weight after being detected by the weight loss type weighing sensor. The feed rate in the nitrogen reactor is 165kg / h. A...

Embodiment 3

[0044] Granular p-nitroaniline is first pulverized by a pulverizer, and passed through a 50-mesh vibrating sieve for subsequent use;

[0045] The continuous diazo method of two kettles in series is adopted, and the effective volume of a single kettle is 3m 3 , with a cooling jacket outside and a cooling coil inside, the liquid level of the single-pot reaction is set to about 90% of the effective volume, and the reaction residence time is about 2.5 hours.

[0046] Add the previous batch of synthesized diazonium salt solution as the bottom material into two diazonium reaction kettles, the amount added is 58% of the full liquid level, start stirring, and feed frozen brine into the jacket and cooling coil. The pulverized p-nitroaniline raw material is fed into the silo of the weighing feeding system, the feeding speed is controlled by the motor speed of the screw feeder, and the feeding amount added to the primary diazonium reactor is detected by the weight loss sensor At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com