Epoxy latent curing agent and corresponding epoxy resin coating

A technology of latent curing agent and epoxy resin coating, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of unfavorable production of composite materials, poor compatibility of solvents, long curing time, etc., and achieve short curing time, Short curing time and good curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

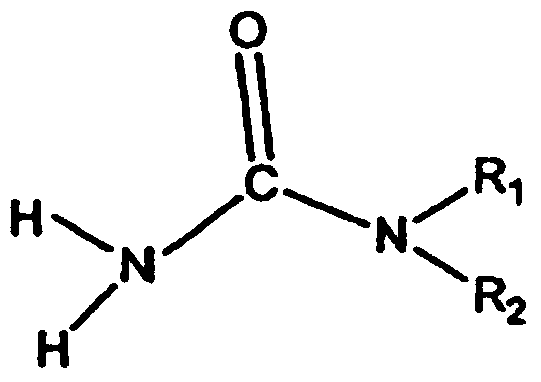

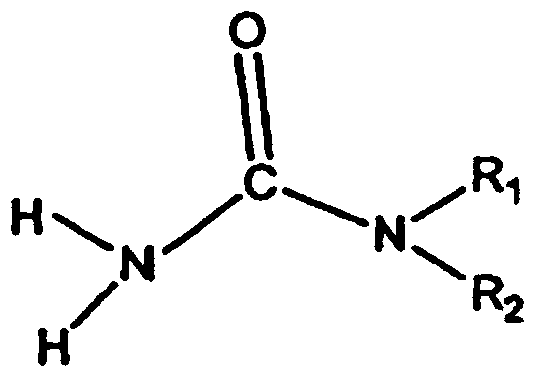

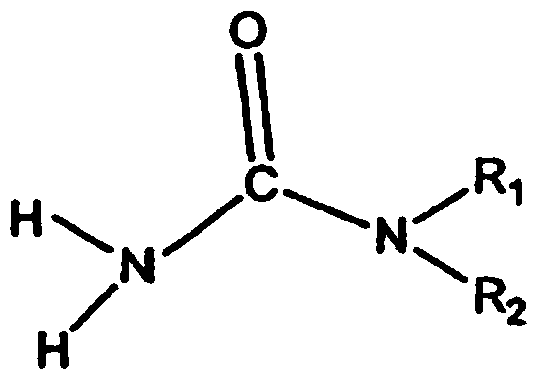

[0017] The epoxy resin latent curing agent includes the following components in parts by weight: 80 dicyandiamide, 30 urea, 40 silicon dioxide, 10 asbestos fibers, and 10 polyglycidyl ethers.

[0018] In this embodiment, the function of urea is to lower the curing temperature of the curing agent and shorten the curing time. The function of the above-mentioned diluent polyglycidyl ether is to reduce the viscosity.

Embodiment 2

[0020] The epoxy resin latent curing agent includes the following components in parts by weight: 90 parts by weight of dicyandiamide, 50 parts by 1,1-dimethylurea, 40~60 parts of silicon dioxide, 10~30 parts of asbestos fiber, 10~20 parts of acetone,

[0021] In this embodiment, the function of 1,1-dimethylurea is to lower the curing temperature of the curing agent and shorten the curing time. The function of the above-mentioned diluent acetone is to reduce the viscosity.

Embodiment 3

[0023] A kind of epoxy resin paint, every 100 parts of water comprises the following composition by mass percentage: epoxy resin 40%, curing agent 15%, pigment 10%, defoamer 15%, thickener 10%, leveling agent 10%.

[0024] The curing agent is the epoxy resin latent curing agent obtained in Example 1, and its curing temperature is low and the curing time is short. The thickener is methylcellulose. The leveling agent is an acrylic leveling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com