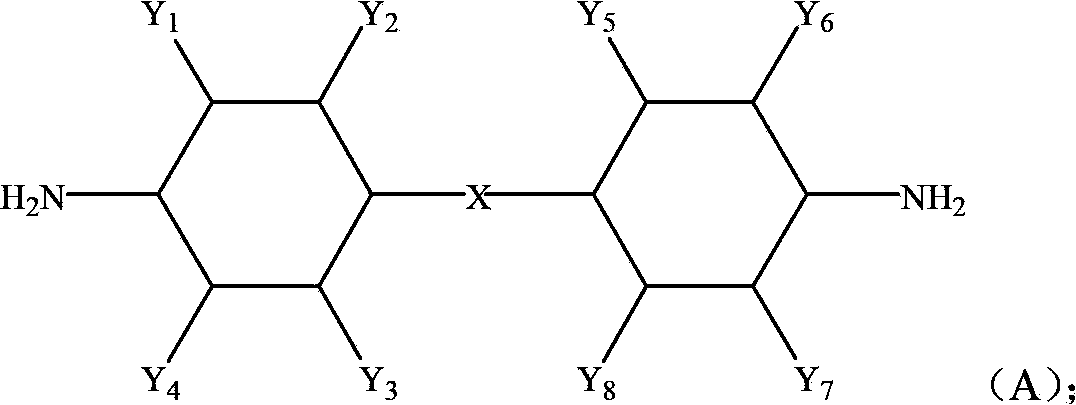

Semi-aromatic polyamide and preparation method thereof, and semi-aromatic polyamide composition and application thereof

A semi-aromatic and polyamide technology, applied in the field of polyamide, can solve the problems of polyamide shrinkage, high water absorption, and easy warping of processed parts, and achieve good warping resistance and glass transition temperature High, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

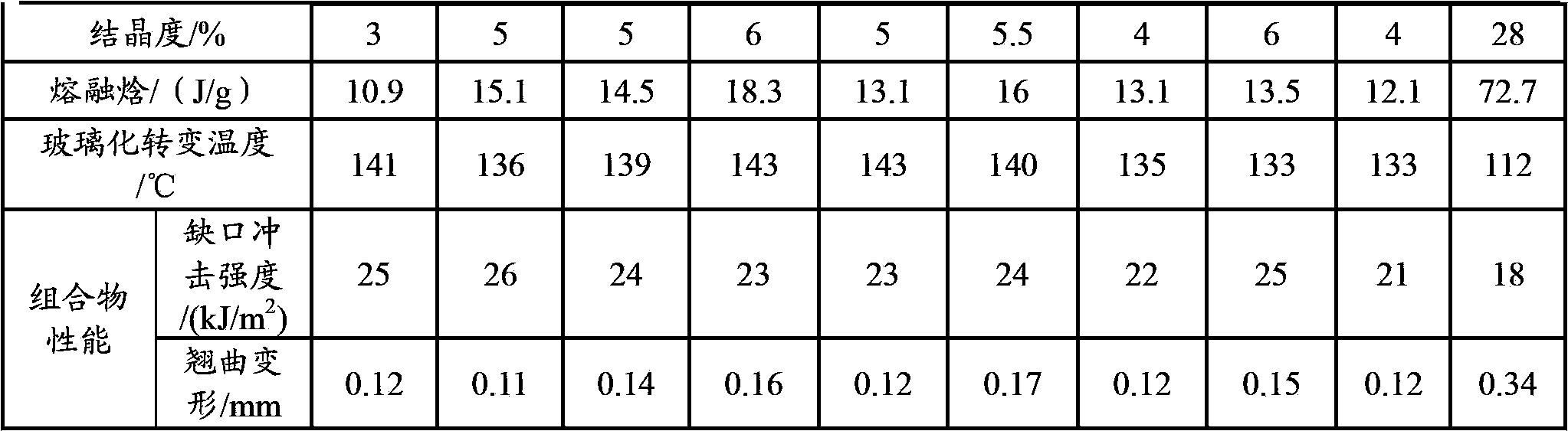

[0032] The preparation method of the semi-aromatic polyamide composition of the present invention is: according to adding 0.1-30 other additives according to 25-60 polyamide, carry out pre-mixing to obtain the premix and add the twin-screw extruder from the main feeding port, 40- 75 Inorganic reinforcing filler was added through side feeding, the mixture was melted and mixed at a screw speed of 300RPM, and the temperature of the screw barrel was 260-300°C, after the molten mixture left the extruder, it was water-cooled and granulated to obtain a polyamide composition.

[0033] An application of the semi-aromatic polyamide composition as described above, the composition is applied in the field of electronics and electricity.

[0034] The substances used in the embodiments of the present invention are all commercially available substances.

[0035] The test methods of the various performances of the above-mentioned polyamides are as follows:

[0036] Melting point, glass transi...

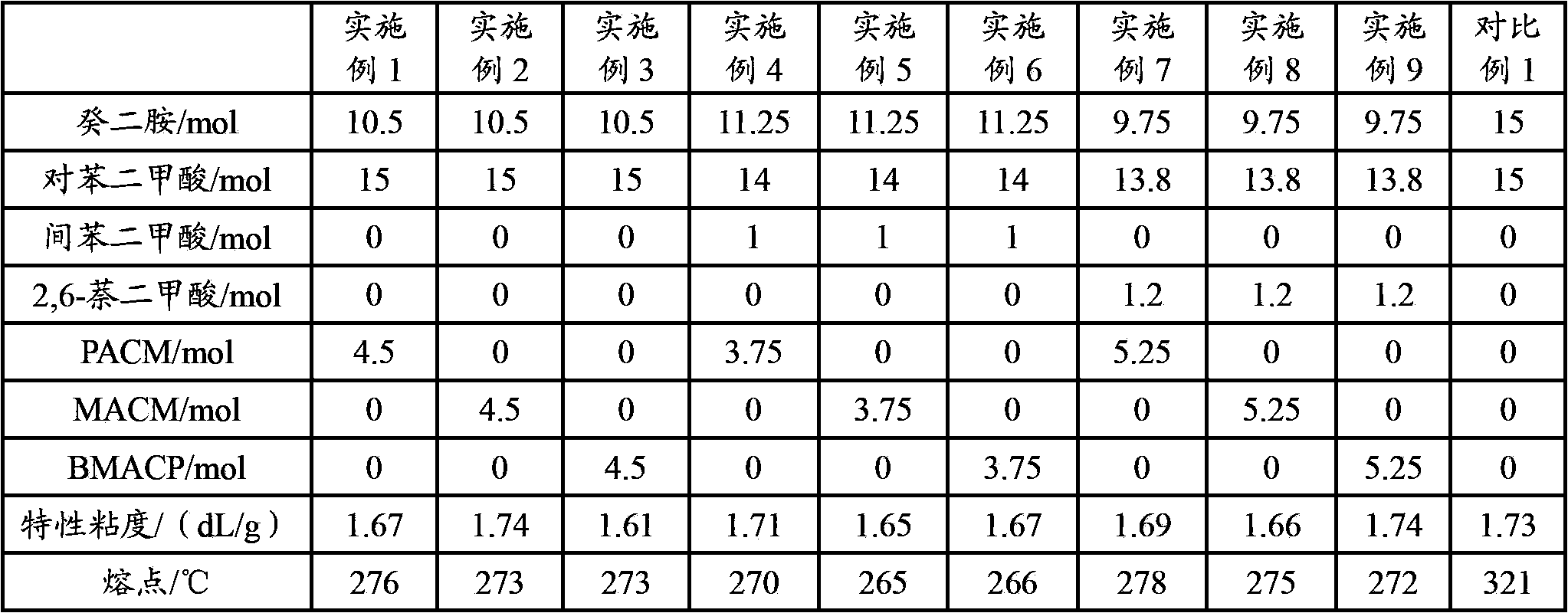

Embodiment 1

[0052]Add 2492g (15mol) of terephthalic acid, 1810g (10.5mol) of 1,10-decanediamine, 947g (4.5mol) of PACM, 73g (0.6mol) of benzoic acid, 5g of sodium hypophosphite, and 2.5 liters of deionized water. The reaction kettle was heated up after deoxygenation-nitrogen flushing cycle twice, and started stirring when it reached 90°C; then continued to heat up under stirring until the temperature inside the kettle rose to 220°C. The reaction was continued at 220°C and 2 MPa for 2 hours by removing part of the water. After the reaction is completed, the material is discharged to obtain a prepolymer. The prepolymer was vacuum-dried at 80°C for 24 hours, and then solid-phase polymerized at 220°C for 10 hours under a nitrogen stream to obtain the final resin, and the melting point, heat of fusion, crystallinity and glass transition temperature of the resin were measured; and measured Its intrinsic viscosity, the test results are listed in Table 1.1. The obtained polyamide is prepared t...

Embodiment 2

[0054] Add 2492g (15mol) of terephthalic acid, 1810g (10.5mol) of 1,10-decanediamine, 1073g (4.5mol) of MACM, 73g (0.6mol) of benzoic acid, 5g of sodium hypophosphite, and 2.5 liters of deionized water. The reaction kettle was heated up after deoxygenation-nitrogen flushing cycle twice, and started stirring when it reached 90°C; then continued to heat up under stirring until the temperature inside the kettle rose to 220°C. The reaction was continued at 220°C and 2 MPa for 2 hours by removing part of the water. After the reaction is completed, the material is discharged to obtain a prepolymer. The prepolymer was vacuum-dried at 80°C for 24 hours, and then solid-phase polymerized at 220°C for 10 hours under a nitrogen stream to obtain the final resin. The melting point, heat of fusion, crystallinity and glass transition temperature of the resin were measured; and measured Its intrinsic viscosity, the test results are listed in Table 1.1. The obtained polyamide is prepared the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com