Oil-proof paper and production method thereof

A production method and oil-proof paper technology, which is applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of reducing paper degradation performance and complicated papermaking process, and achieve excellent degradability, reduced consumption, and reduced costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

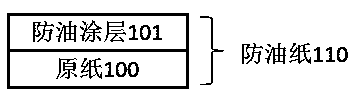

[0020] The preparation method of greaseproof paper 110 of the present invention, its steps are as follows:

[0021] (1) Provide the initial base paper 100 .

[0022] (2) Preparation of composite oil-proof coating

[0023] Using starch, plasticizer, coalescent, fluoropolymer and water, the temperature of the water bath heated in the water bath is 70-95°C

[0024] The starch and the film-forming aid are dissolved under the condition of 5-30 minutes, and the starch, the plasticizer, the film-forming aid, the fluorine-containing compound and water are mixed under the condition of stirring for 5-30 minutes to prepare a composite oil-proof coating.

[0025] (3) Coating a composite oil-repellent coating on the surface of the base paper 100 and drying it with hot air at a drying temperature of 70-105° C. to form an oil-repellent coating 101 . A coating machine is used to apply the composite oil-repellent coating to the surface of the base paper 100 . After drying, the moisture in t...

example 1

[0030] Base paper 100 is made of transparent paper with a basis weight of 20 g / m 2 .

[0031] Composite oil-proof coating: 100 parts of starch, 10 parts of plasticizer, 100 parts of film-forming aid, 20 parts of fluorine-containing compound. The starch is natural starch. Described plasticizer is glycerol. The film-forming aid is polyvinyl alcohol. The fluorine-containing compound is perfluoropolyether phosphate, and the solid content of the coating is 5%.

[0032] Dissolve starch and film-forming aids under the condition that the water bath temperature of the water bath is 70°C, and then mix the starch, plasticizer, film-forming aids, fluorine-containing compounds and water at a speed of 80 r / min. Stir for 5 minutes to prepare a composite oil-proof coating.

[0033] Use a composite oil-repellent coating to form an oil-repellent coating on the surface of base paper 100 by roll coating, with a coating weight of 9.5 g / m 2 , and use hot air to dry at a drying temperature of ...

example 2

[0036] The base paper 100 is translucent paper with a basis weight of 32 g / m 2 .

[0037] Composite oil-proof coating: 100 parts of starch, 40 parts of plasticizer, 50 parts of film-forming aid, 30 parts of fluorine-containing compound. The starch is modified starch. Described plasticizer is sorbitol. The film-forming aid is cellulose. The fluorine-containing compound is perfluoropolyether phosphate, and the solid content of the paint is 15%.

[0038] Dissolve the starch and film-forming aids under the condition that the temperature of the water bath heated by the water bath is 95°C, and then mix the starch, plasticizer, film-forming aids, fluorine-containing compounds and water at a speed of 200 r / min. Stir for 30 minutes to prepare a composite oil-proof coating.

[0039] Use a composite oil-repellent coating to form an oil-repellent coating on the surface of base paper 100 by roll coating, with a coating weight of 1 g / m 2 , and dried with hot air at a drying temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com