M-shaped tractive digitalized energy-saving oil pumping unit

A pumping unit and traction technology, which is applied in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of hidden safety hazards, inconvenient moving machines, uncontrollable breaking and disengagement of polished rods, and uncontrollable counterweights. The effect of convenient wellhead operation, simple structure, and convenient and quick adjustment of technical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

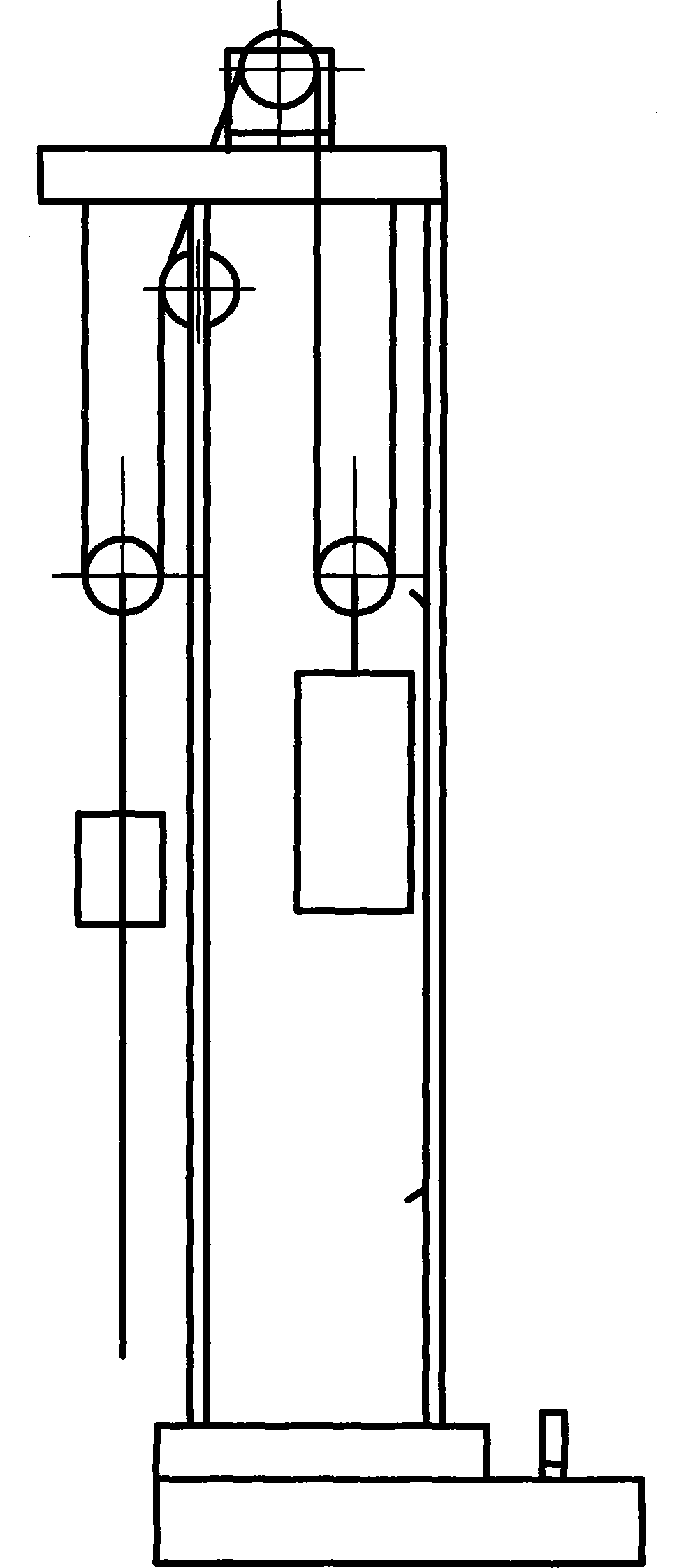

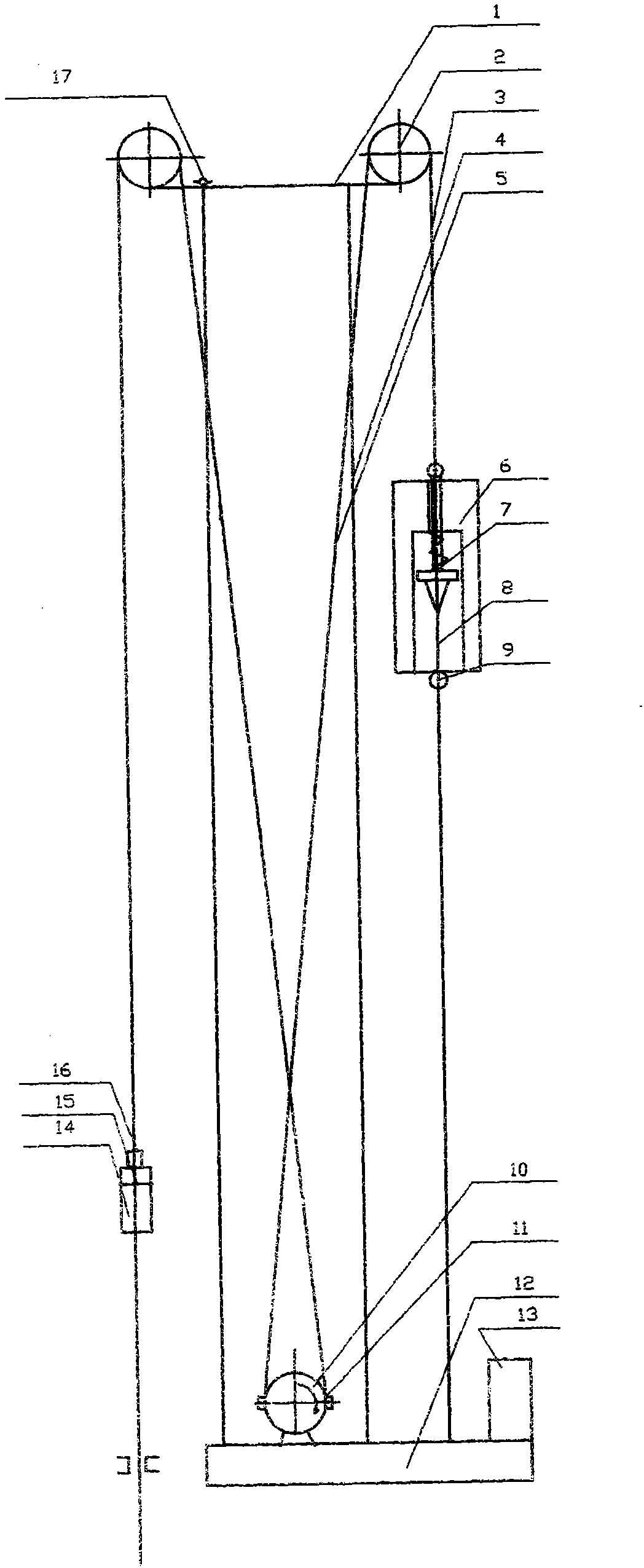

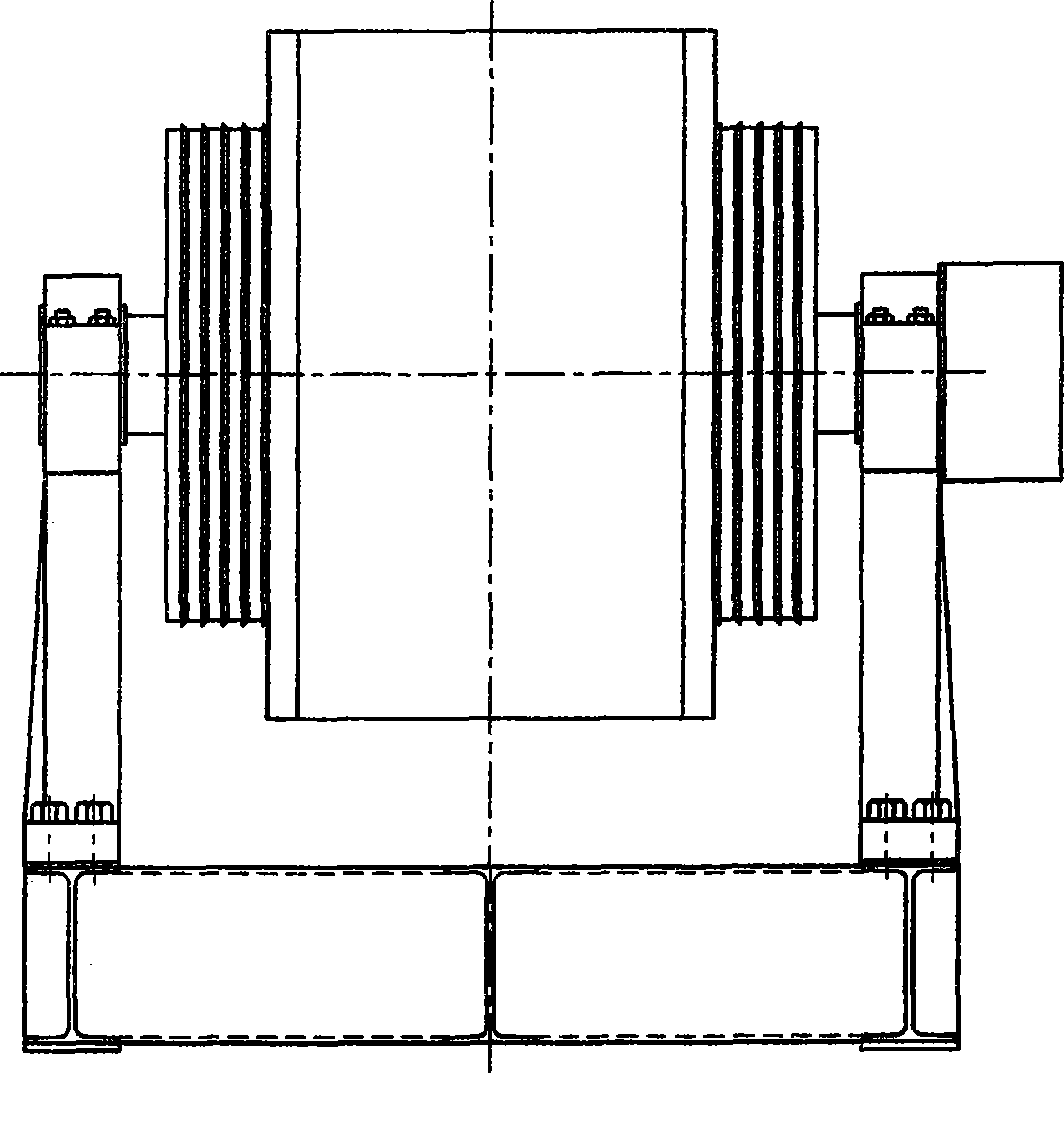

[0025] exist figure 2 Among the embodiments: 1. is the upper platform of the pumping unit, which is welded with section steel, and the upper platform 1 is the base of the fixed pulley 2, and it is installed on the frame 4. The frame 4 is the carrier of the pumping unit, made of section steel, and it is installed on the concrete foundation 12. The 2nd, fixed pulley, fixed pulley utilizes MC to make, and fixed pulley seat utilizes cast steel to make. image 3It is a structural diagram of the motor 10, and the motor is designed as a rare-earth permanent magnet synchronous motor with low speed and high torque of the outer rotor. The motor 10 is installed on the concrete foundation 12, and traction wheels are arranged on both sides of the motor 10 for power transmission by flexible cables. A brake system 11 is installed on the outer edge of the outer rotor of the motor 10 . The power of motor 10 is transmitted by wire rope 5, fixed pulley 2. 3 is the M-type traction system. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com