Heat exchange system

A technology of heat exchange system and heat exchanger, applied in the field of heat exchange system, can solve the problems of low utilization value, high energy consumption, underutilization, etc., and achieve the effect of simple structure, low investment cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

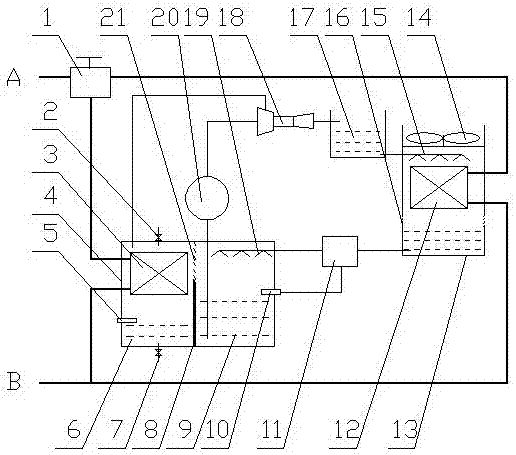

[0030] Two subsystems: a closed subsystem and an open subsystem.

[0031] The No. 1 heat exchanger 3 and the No. 2 heat exchanger 12 in the closed subsystem are connected in parallel by pipes, and the two ports A and B of the pipes are connected to the workstation.

[0032] The phase change device 4 in the open subsystem is a sealed box structure, which is divided into a condensation chamber 6 and a vaporization chamber 9 by a partition 8 and a steam louver 21. The partition 8 is located under the steam louver 21; the vaporization chamber 9 The liquid outlet of the liquid outlet is sequentially connected to the nozzle of the pump 20 and the ejector 18, and the negative pressure chamber of the ejector 18 is connected to the gas outlet of the condensation chamber 6; a liquid vapor nozzle 19 is installed above the vaporization chamber 9, and the inlet of the liquid vapor nozzle 19 is connected to a heating device 11, the liquid inlet of the heating device 11 is connected to the h...

Embodiment 2

[0036] On the basis of Example 1, a liquid diverter valve 1 is installed at the parallel inlets of the No. 1 heat exchanger 3 and the No. 2 heat exchanger 12 . In this embodiment, the liquid medium flowing through the No. 1 heat exchanger 3 and the No. 2 heat exchanger 12 is proportionally distributed through the liquid splitter valve 1 .

Embodiment 3、4

[0038] On the basis of Embodiment 1 and 2 respectively, air intake valve 2 and drain valve 7 are set above and below condensation chamber 6, and condensed water level sensor 5 is installed in condensation chamber 6, when condensed water level sensor 5 detects When the liquid level of the condensed water is higher than the set value, the intake valve 2 and the drain valve 7 are opened at the same time, and the intake is discharged; otherwise, the intake valve 2 and the drain valve 7 are both closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com