Preparation method of iron-based nanocrystal spectroscopic standard sample

A technology for iron-based nanocrystals and spectral standard samples, which is applied in the field of preparation of iron-based nanocrystals spectral standard samples, can solve the problems of difficulty, few iron-based nanocrystalline standard samples, and large component segregation of samples, and achieves accurate effect of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0018] The preparation method of the iron-based nano crystal spectrum standard sample provided by the invention provides guarantee for the development and production of the iron-based nano crystal material.

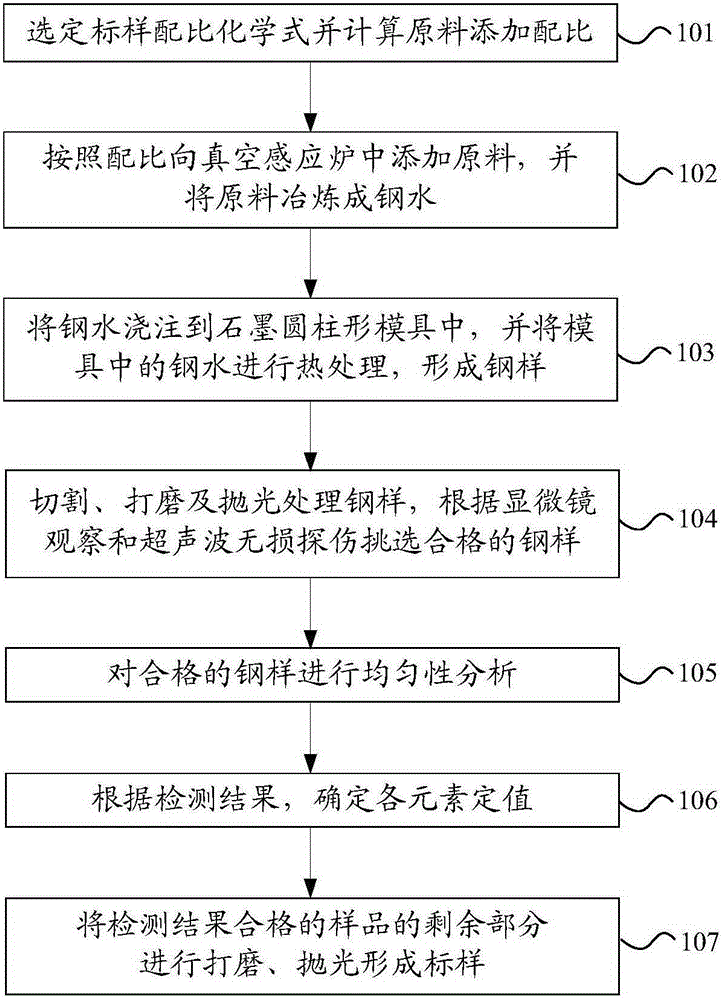

[0019] figure 1 It is a flowchart of the iron-based nanocrystal spectral standard sample preparation method of the present invention, as shown in the figure, the method includes:

[0020] Step 101, using the iron element as the base, select the chemical formula of the standard sample ratio and calculate the raw material addition ratio; the added raw materials include industrial pure iron, ferro-boron fragments, ferro-niobium fragments, silicon fragments, and electrolytic copper.

[0021] Specifically, taking iron as the base, silicon, boron, niobium and copper as the high and low standards, distributed in steps, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com