Quantitative metallographic analysis method for phase M23C6 of Super 304H steel

A quantitative metallographic and analysis method technology, applied in the field of quantitative metallographic analysis, can solve the problems of target precipitated phase loss, low extraction efficiency, high material consumption, etc., and achieve fast and accurate quantitative analysis, wide observation range, and simple sample preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

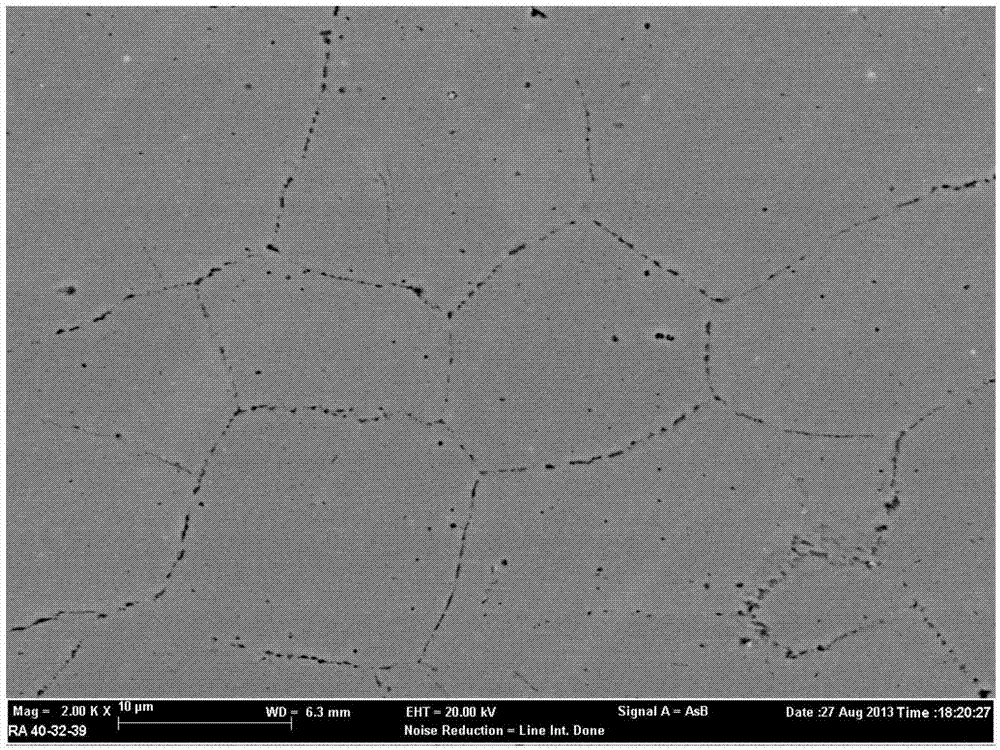

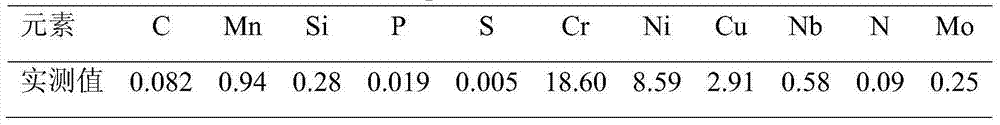

[0026] The composition is shown in Table 1, the specification is Φ48×9mm, the service temperature is about 600-610°C, and the M in the Super304H steel pipe that has been in service for 41,000 hours 23 C 6 The calculation of the volume percentage content of the phase is taken as an example to illustrate the specific operation steps of the present invention.

[0027] The chemical composition (wt.%) of table 1 embodiment Super304H stainless steel

[0028]

[0029] Step 1, metallographic sample preparation.

[0030] Cutting: Use a grinding wheel cutting machine to cut small samples of Super304H steel pipes, and keep cooling with cooling water during the cutting process.

[0031] Mounting: after the sample is ground flat, the conductive thermal mounting material is used to mount the sample.

[0032] Grinding: Grinding the metallographic observation sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com